Engineering Enhanced Humans

Prosthetic engineering has not found a solution for everyone. How does experiencing exclusion from everyday life feel?

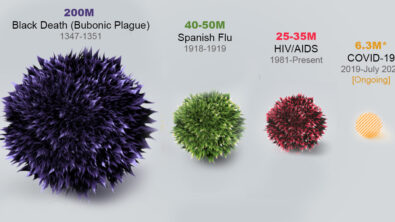

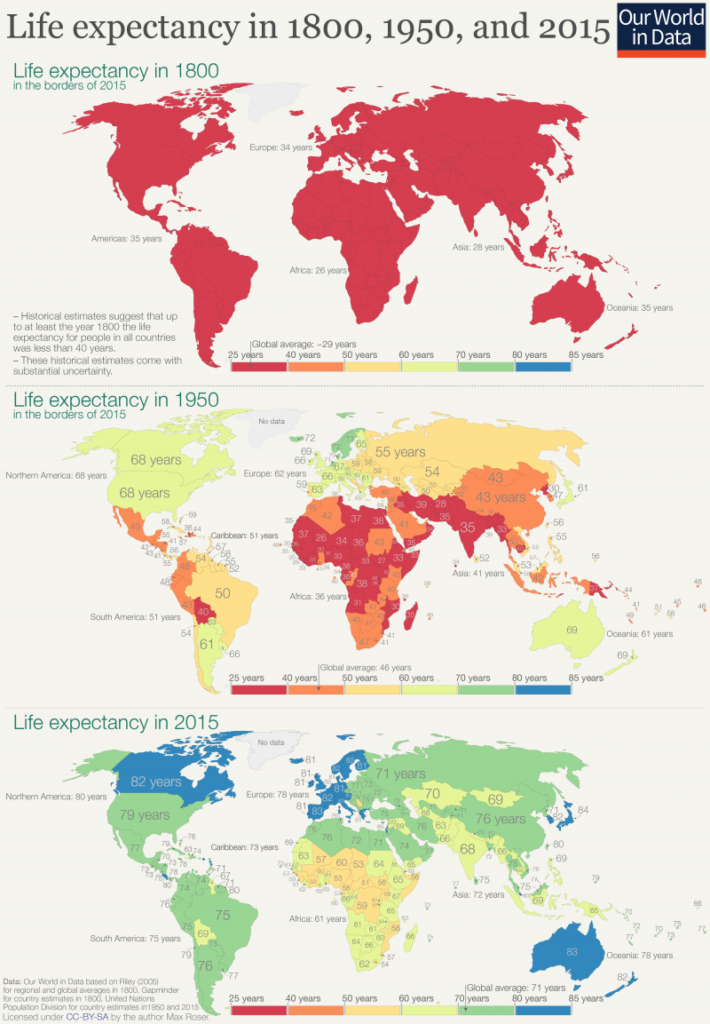

One billion people live with disabilities. They are the world’s largest minority. And if you are like me, the term conjures up mental images of people with a permanent type – missing a limb or suffering from a debilitating disease. However, data suggests that most of us will experience being temporarily disabled at one point. We are becoming increasingly susceptible to the sicknesses and frailties that aging brings. Just two hundred years ago, no country had a life expectancy above 40.

Now, in regions with life expectancies over seventy, individuals spend about eight of them (11.5%) living with a disability, which may be temporary due to a resolvable health problem. For over a decade, the World Health Organization (WHO) has recognized the severity of this problem and has been sounding the alarm.

“This issue will become more acute as the demographics of societies change and more people live to an old age”

WORLD REPORT ON DISABILITY, WHO Library Cataloguing-in-Publication Data

The direct costs for medical treatment, prosthetics and other interventions are easy enough to compute, though they will vary regionally due to widely different socio-economic factors and healthcare models. The indirect costs, monetary and psychological, are harder to put a precise figure on because of the widespread impact of being excluded from everyday life the majority are free to live. They go to the core of modern life in developed nations: freedom of autonomy, choice in leisure pursuits and ability to gain and hold employment.

An estimated 386 million of the world’s working-age people have some kind of disability

World Health Organization

Physical disabilities impact everyone differently. Objectively evaluating an individual’s quality of life is difficult, but that hasn’t stopped the WHO from trying to measure and ultimately benchmarking it. Avoiding exclusion means leveling the playing field and ensuring accessibility for everyone.

Mechanical replacements with prosthetic engineering

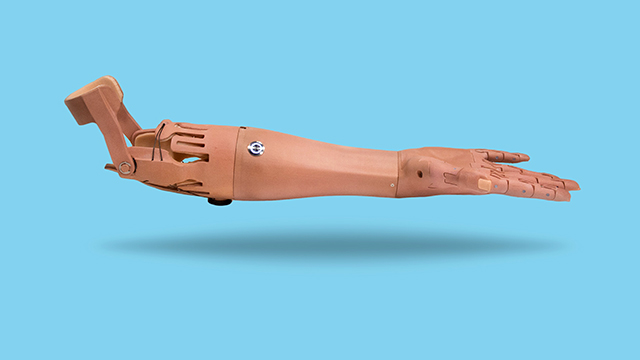

Finding mechanical ways to address disability is far from a new concept. Rudimentary prosthetics date as far back as 700 BC. The modern approach, which focuses on a return to functional status for complex tasks to be performed and on enabling the disabled to return to the workforce, is primarily attributed to many traumatic amputations due to World War I. The evolution of prosthetic engineering continued over the 20th century, with technological advances making their functionality more complex to better mimic the biological component they are replacing.

Global extrapolations are problematic, but a recent US study states that the amputation rate among combatants in recent US military conflicts remains at 14-19% and the devastation caused by land mines continues, particularly when displaced civilians return to mined areas and resume agricultural activities.

Artificial limbs, The BMJ

The more faithful the device’s behavior, the more complex the task can be completed, resulting in the person having greater autonomy and “accessibility to everyday life,” as I alluded to earlier. However, due to cost and manufacturing limitations, there remain challenges that haven’t been adequately addressed to ensure all amputees receive a durable, comfortable, and functional prosthetic.

Anthropometry is the measurement and proportions of the human body, which is unique for each person. The fit and comfort of a prosthetic device depend on tailoring it to the specific anthropometry of an individual. All morphological physical features of the human body change throughout one’s life span. With children, there is rapid change. Adults remain fairly stable for 15 years, then start to decline, albeit gradually.

“.. the complexity of amputations is not considered, until you must get fitted for a prosthetic. Every amputee is different depending on the limb/s lost, the type of amputation, the amount of limb left, the wound, the amount of muscle left …”

Debbie Searle, Journey on my Prosthetic Leg

That’s an excerpt from a blog by my colleague Debbie Searle. It is a first-person perspective that highlights the challenges an amputee like her continues to face despite the discipline of prosthetic engineering being well over a century old. Bespoke solutions are necessary to ensure the best fit, comfort, and more effortless performance of tasks.

Making a prosthetic that is a good fit can be a lengthy process, and in the case of children, it might be obsolete on arrival. The cost of these prosthetics remains prohibitive, even in the wealthiest nations. In the United States, a prosthesis can range in cost from $5000 to $50000.

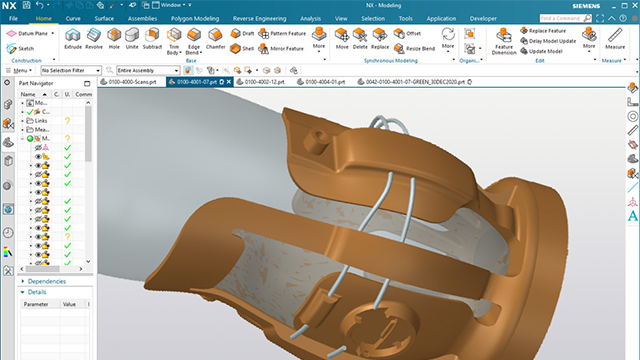

Creating a lightweight prosthetic limb capable of mimicking the behavior of a biological one is arduous. Take, for example, a prosthetic foot. Imitating the movement of walking would be very different from running or climbing stairs. Using digital twins and engineering simulations allows for the conditions of different tasks to be simulated, which would be far more time-consuming and expensive if only done with physical prototyping and testing each task. Simcenter solutions offer the full range of simulation domains required to model and understand prosthetic engineering: the articulations and durability of prosthetic limbs while limiting design cycles and physical prototypes to reduce costs.

Disrupting pediatric prosthetics engineering

By using additive manufacturing and NX automated optimization and parametric design, Unlimited Tomorrow is disrupting the pediatric prosthetics industry by reducing the time and cost of developing arm prosthetics. In 2019, they introduced True Limb, the industry’s first lightweight, affordable multi-articulating prosthetic limb with a realistic appearance, which costs far less than alternatives and can be delivered in weeks.

Mechanical augments

If you are a science fiction fan, the concept of exoskeletons or augmenting ourselves with mechanical devices, is probably very familiar. The final battle sequence in one of my favorite movies, Aliens, features an exoskeleton-clad Sigourney Weaver facing off with the much larger queen of the alien xenomorph species.

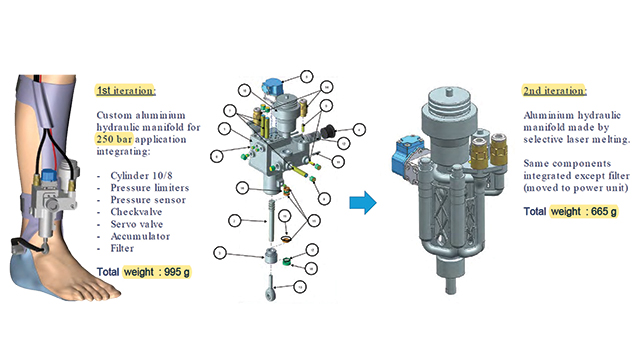

In the present, while they might seem far less fantastical and less likely to help in the act of regicide, exoskeletons are a reality. HES-SO University of Applied Science and Arts is working on developing a hydraulic actuator for an ankle exoskeleton to assist in the rehabilitation of stroke victims. The rehabilitation requires repetitive walking practice to maximize neural recovery. Not all individuals can practice walking without a therapist’s assistance after a stroke.

Robotic exoskeletons are a new generation of robotic-assisted gait training devices that assist lower limb movement and allow repetitive walking. These exoskeletons can significantly improve functional recovery and psychological well-being after a stroke during rehabilitation. Simcenter has been a valuable tool for students who must virtually troubleshoot hydraulic systems in which malfunctions have been intentionally included.

Exoskeletons have the potential to redefine our productivity by reducing the strain on our bodies, assisting in difficult or almost impossible physical feats, and diminishing the chance of injury. With shortages in the workforce afflicting many regions globally, this disruptive technology could be a game-changer, as this news article highlights for the construction industry: The future is now: how exoskeletons are changing Canada’s construction industry

Maintaining our functional status

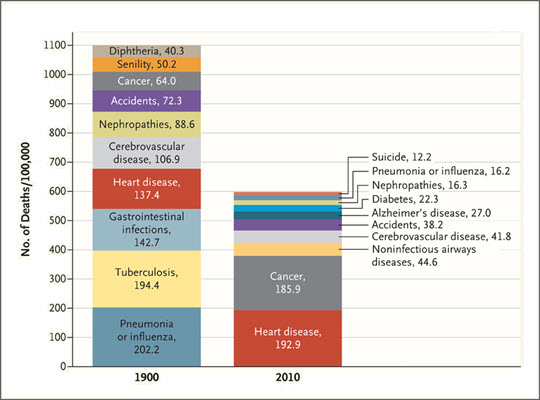

The average life expectancy of humans continues to grow, attributable to a wide range of factors such as socio-economic changes, nutrition, pharmaceuticals, research into, and a general understanding of diseases and bacteria. Some argue the first humans to live to the age of 150 are already alive. But living longer doesn’t stop the decay. Muscle loss, frailty, and medical conditions that come with aging are rising, as seen in this interactive chart which compiles the Top 10 Causes of Death in the United States from 1900–2010.

Medical advances have increased our life expectancy, which means diseases and frailties that impact us later in life (such as cancer) have a higher mortality rate. Heart diseases have become the number one cause of death globally. How can computer-aided engineering help?

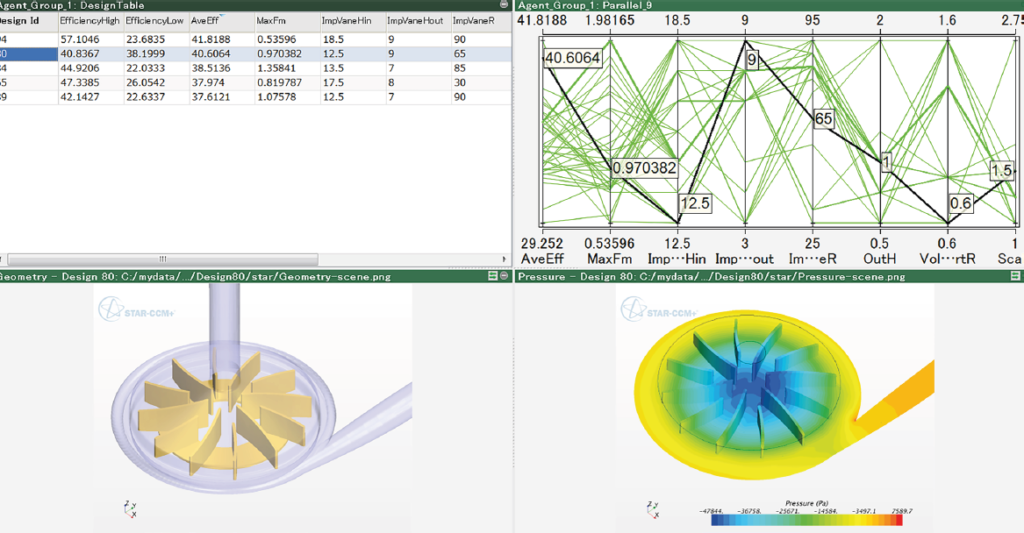

At Terumo, SImcenter’s computational fluid dynamics is used to develop blood pumps in cardiovascular surgical devices. The purpose of the computational fluid dynamics-based design exploration is to increase the efficiency of blood pump development and bring devices to market faster.

Surgical medical treatments require life-sustaining pumps for intravenous infusions and drug delivery. B&W Engineering leveraged Simcenter to design a more efficient peristaltic pump with the lowest drug delivery rate on the market.

Orthopedic replacements

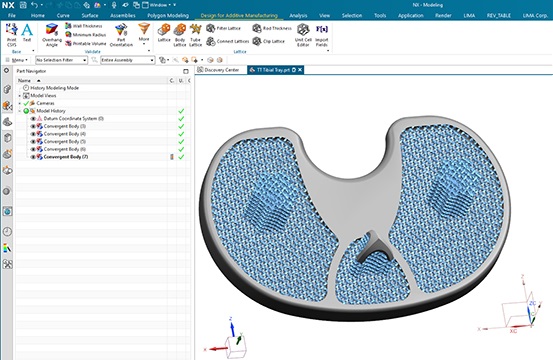

Not only do you probably know someone who has had a knee or hip replacement, but you are also more likely to have one yourself. According to the American Academy of Orthopaedic Surgeons (AAOS), more than 450,000 total hip replacement surgeries are done annually in the United States. This number is expected to reach 635,000 surgeries annually by 2030. Not only is demand increasing. With our longer life expectancy, the lifetime of orthopedic implants also needs to be extended. Developing a robust and easy-to-manufacture orthopedic solution is essential. This is the challenge facing LimaCorporate, which saw the value of using lattice-based metals as the solution for longevity. Their 3D printed hip cup was realized with NX AM and Siemens software ecosystem to cut design iterations, reduce errors and boost reliability.

No limits

As I finish this piece, an interview on the radio catches my attention. The reporter talks with a physically disabled man after finishing a marathon. They don’t describe in detail what are his particular disabilities, only that he required the use of several prosthetic devices to participate. “I don’t believe in limits.” It is this mindset to which he attributes his success – a common mantra for most athletes. However, in this case, without the prosthetics, there would be no way for his will to manifest into action. There are far simpler tasks that many disabled or elderly individuals cannot accomplish because the cost, fit, and durability of prosthetics and implants make them impossible. With that same determination and prosthetic engineering innovation, we can help include millions more in everyday life with no limits.