Overcome the Barrier to Faster CAE Geometry Preparation

Ask almost any simulation expert and they will tell you that geometry preparation is the most time consuming part of CAE analysis. It doesn’t have to be this way though. What if you could cut down on the time you spend on this painfully tedious task? Think how you could use those extra hours of your day. Today you will see how more efficient workflows are possible with NX CAE.

Ask almost any simulation expert and they will tell you that geometry preparation is the most time consuming part of CAE analysis. It doesn’t have to be this way though. What if you could cut down on the time you spend on this painfully tedious task? Think how you could use those extra hours of your day. Today you will see how more efficient workflows are possible with NX CAE.

First, let us examine the traditional process of preparing geometry for CAE analysis that you are probably all too familiar with. In this process, you spend a significant amount of time remodeling geometry to resolve inaccuracies and/or reduce complexity.

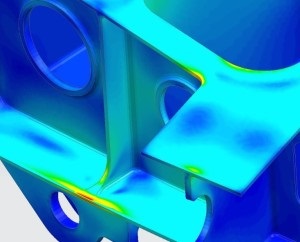

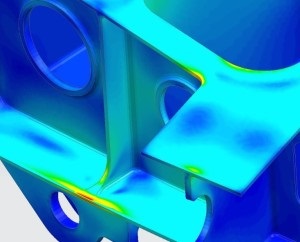

Often when you have a product design, there are inaccuracies in the model that may not necessarily affect the appearance or design of the product, but which will have an impact on analysis. Some examples are gaps between faces or sliver surfaces that are uneven. If you try to perform analysis without fixing these inaccuracies first, you are going to run into trouble when it comes time to create the mesh.

Similarly, complex models can cause problems when it comes time to perform analysis. You may have a model that features a lot of blends, fillets, or holes that are irrelevant to CAE analysis. These features take longer to mesh and increase the solve time, so it is necessary to remove them as part of preprocessing.

So, just how long does remodeling geometry take? It varies, of course, based on the person performing the analysis along with the product, but generally speaking, it can take a day or more to complete. Worse still, you have to repeat this process for each and every design iteration. No wonder simulation experts cite geometry prep as their most time-consuming task!

The amount of time it takes to cleanup geometry also depends upon the tool—that is, software application—you’re using. Most companies use one of the following kinds of software:

- History-based CAD

or - CAE specific preprocessor

With a history-based CAD system, it can take anywhere from 10 to 20 minutes to defeature a model. You have to locate the feature you wish to edit, and then make all of the necessary changes. Once you edit the feature, you need to update the model. At this stage, you run the risk of breaking the model due to downstream issues with any geometry associated to the feature you changed. You then have to go through and correct all of these. Following an iterative process will only add more time.

A CAE specific preprocessor, on the other hand, takes even longer! Use one of these, and you can expect the model defeature process to take hours or even days to complete. You can’t edit features directly. Instead, you have to defeature the model through edits to the mesh. Then you have to ask the design team to update the model. These steps have to be repeated for any future design changes.

The solution is a tool that offers you the flexibility and freedom to switch seamlessly between CAD and CAE, without the need to consult or rely upon anyone else. You can defeature a model in 10 seconds. This is thanks to the power of Synchronous Technology. Synchronous allows for fast, direct changes to the geometry without an understanding of the model’s history. Once changes are made, complete associativity between geometry and mesh allow you to automatically update the mesh in seconds. No need to manually recreate anything.

You can’t truly understand the power this capability gives you until you see it yourself in action. Level surfaces and remove blends, all with a single touch using Synchronous.

Even from the first iteration you see the difference, but the true benefit comes when your design changes. The analysis model is always associated to your design, so NX CAE automatically updates it to accommodate any design changes down the line.

Furthermore, the ease with which you can make changes and update the mesh allows you to perform quick “what-if” studies so as to determine the optimal design. You almost instantly see how your changes impact the performance of the analysis model. No more will you have to throw your model over the wall and wait.

A single interface for design and simulation tasks increases productivity by allowing you to perform rapid design iterations with automated updates. By making simulation concurrent with the design, you are able to reduce product development timescales. You can even reuse data to create shell properties.

To see the difference Synchronous makes on a traditional CAE workflow for yourself, watch the replay of the webinar How to Create Fast and Efficient CAE Workflows, upon which this blog post was based.