Tomorrow’s power, today: optimizing marine engine performance with system simulation

IMO GHG 2050, ECA, Tier III, Sulphur Cap 2020 … These acronyms are a clear source of headaches for shipyards, suppliers and ship owners and represent an additional pressure on their engineering teams. The emission regulations are getting more stringent every year. Ship propulsion systems are both the origin of, and the solution to the problem. What do I mean by that? Read on to find out!

The problem: marine engines are the source of the emissions

Today, most ocean-going vessels are propelled by a main engine usually running on heavy fuel oil or marine gasoil. These engines are efficient, robust and safe but also emit some by-products (NOx, SOx and of course CO2).

Plenty of technologies are being explored to reduce these emission levels, such as dual fuel, hydrogen or ammonia combustion, hybrid propulsion systems, scrubbers, fuel cells… But how do we know which of these technical solutions are a good fit for a given vessel? How do we balance satisfying emissions regulations with meeting commercial viability requirements for shipowners?

The solution: optimize marine engine performance with system simulation

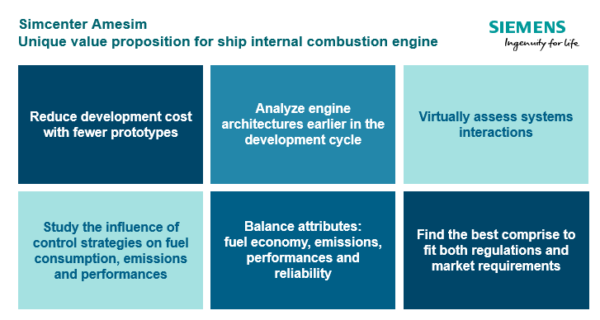

Given the time and cost involved, it is impossible to prototype, commission and test every solution (or combination of solutions) for every ship type. But there is a fast, cost-effective solution: using system simulation.

System simulation allows you to quickly simulate any engine system by solving physics-based or data-based models or a combination of both. Most of the engine models (quasi-static, mean value or crank angle based) are real-time capable and allow for verification of the controller in closed-loop, using Hardware-In-the-Loop methodology. In addition, these models can be coupled to CFD codes including Simcenter STAR-CCM+ for increased realism.

This is why optimizing marine engine performance with system simulation is a reasonable option.

Ready to learn more?

Watch this on-demand webinar to see how Simcenter Amesim is the solution to optimizing marine engine performance, and meeting your targets. Indeed, the webinar covers the following topics:

- In-cylinder combustion

- Engine thermal management

- Intake, exhaust and engine actuation

- After-treatment systems

- Fuel systems

- Electrification

- Engine integration

But don’t take my word for granted. Learn how one of the largest shipbuilders in the world, Hyundai Heavy Industries, use Simcenter Amesim in their hybrid propulsion systems design.