Introducing Simcenter HEEDS Connect Systems MDO

Simcenter HEEDS Connect enables global collaboration and flexible resource management with its web interface, allowing teams to share, monitor, and review Simcenter HEEDS study results. Now it also has exclusive new features that improve design space exploration and optimization.

This blog highlights Simcenter HEEDS Connect Systems MDO (Multidisciplinary Design Optimization) and explains the benefits it brings.

Collaborative distributed optimization with Simcenter HEEDS Connect Systems MDO

Designing advanced products across the aerospace, automotive, and energy industries requires optimization of many systems that interact with each other in a complex way.

These interdependent subsystems are governed by distinct performance and functional requirements that are typically managed by specialized design teams that must ensure compatibility and avoid conflicts to achieve overall performance targets. However, these teams are often geographically dispersed across facilities, regions, or even globally, posing significant challenges for coordination and integration.

Simcenter HEEDS Connect Systems MDO enables collaborative distributed optimization of these complex systems wherever different design groups are located by:

- Supporting Model Based Systems Engineering (MBSE) practices

- Integrating disciplinary studies into a unified and scalable optimization framework that captures the behavior of the complete system

- Managing the coupling of the system and the mutually interdependent studies

- Finding superior designs by exploiting the interactions between the different disciplinary studies

Design Structure Matrix

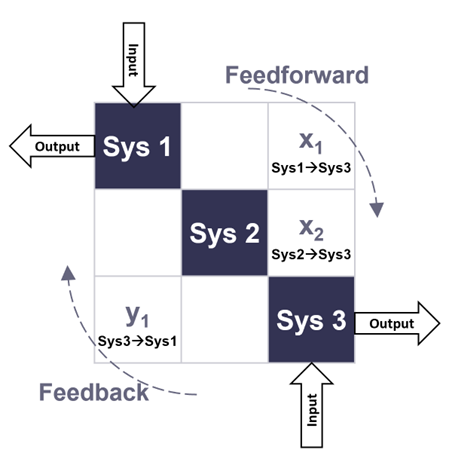

Simcenter HEEDS Connect Systems MDO uses a Design Structure Matrix (DSM), also known as an N-squared (N²) Matrix to represent a complex system and the dependencies and interactions between its components.

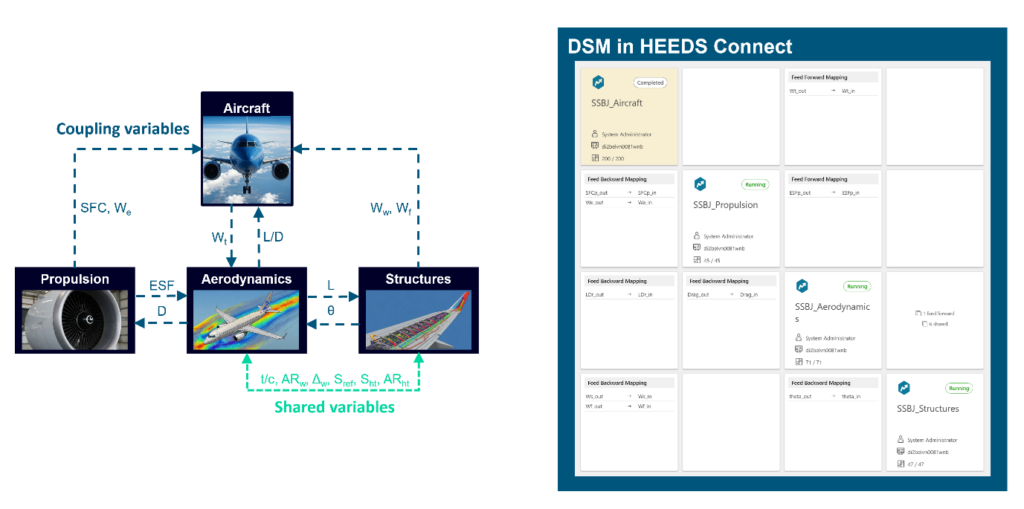

Different disciplinary studies are listed along the diagonal (such as propulsion, aerodynamics etc.), while their interactions are represented in the off-diagonal elements. These interactions can be categorized as feed-forward, feedback, or shared dependencies. Inputs to the disciplinary studies are assigned to the vertical columns of the matrix, while outputs from the studies are placed along the horizontal rows, enabling a structured representation of system interdependencies.

The schematic representation of the supersonic business jet problem (using a problem definition published by Tosserams et.al 2010), including its coupling and shared variables, is shown below with the corresponding DSM in Simcenter HEEDS Connect Systems MDO.

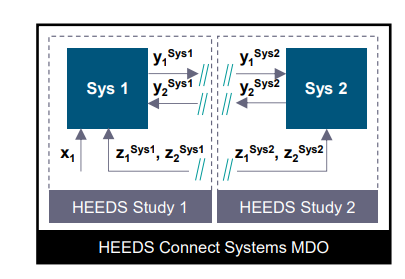

Distributed architecture

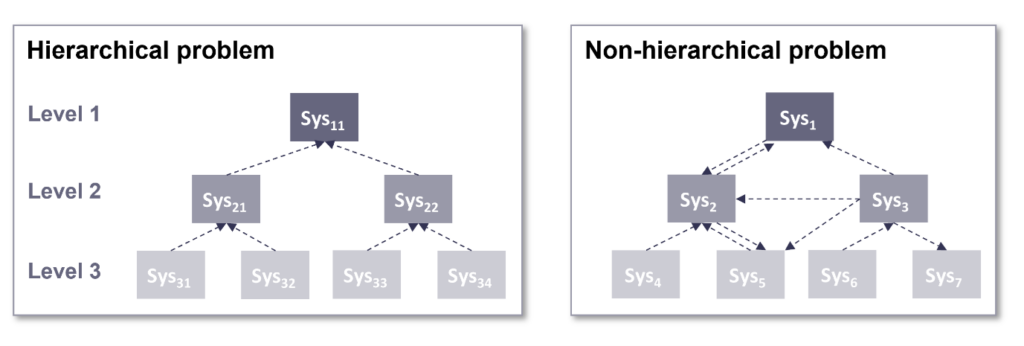

MDO using traditional monolithic architecture treats all the disciplinary analysis entities together as part of one optimization. Whereas Simcenter HEEDS Connect Systems MDO uses distributed architecture based on Non-Hierarchical Analytical Target Cascading (NHATC) method to split the entities into different studies which are all optimized individually but then linked together and coordinated. Consistency is enforced by a coordination algorithm that relies on the augmented Lagrangian method.

This approach helps to tackle both hierarchical problems, where the interconnection is only between a parent and child, and non-hierarchical problems where any subsystem can be linked to another.

Discover more

This is part two in our three-part series introducing Simcenter HEEDS Connect and its capabilities. If you missed the first blog, Simcenter HEEDS Connect enables collaboration anywhere with anyone, be sure to check it out to learn how Simcenter HEEDSConnect facilitates seamless teamwork and data sharing. Look out for the final blog soon where we’ll be talking about a new feature that increases collaboration with web-based workflows within Simcenter HEEDSConnect.

In the meantime, discover how Simcenter HEEDS can accelerate your product development process through automated workflows and optimized computational resources that lead to innovative design solutions.

[Tosserams 2010] – Tosserams, S., Kokkolaras, M., Etman, L. F. P., and Rooda, J. E. (2010). “A Nonhierarchical Formulation of Analytical Target Cascading.” ASME. J. Mech. Des. May 2010; 132(5): 051002. https://doi.org/10.1115/1.4001346