HPC and NX Nastran: Robust Solutions for Mercedes-Benz Simulations

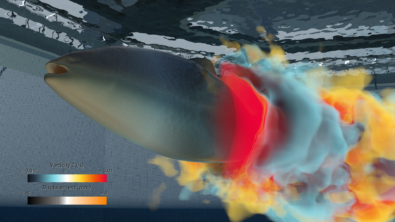

Daimler Mercedes-Benz has been using simulation in R&D for around 50 years. What started as in-house developed solutions for vehicle design eventually evolved, and the use of more detailed models has made high-performance computing (HPC) a necessity.

Equally important is the time it takes to get results back from the analyses. “In the past, we had to wait several days,” says Dr. Kohler. “Today we are able to obtain results overnight.”

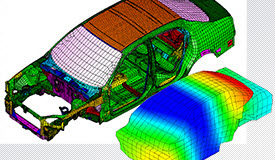

Mercedes-Benz uses NX Nastran for NVH and structural analysis, while LMS Virtual.Lab handles chassis simulations.

Between the sheer magnitude of the simulations and the need for faster turnaround times, it’s obvious why Mercedes-Benz requires high-performance computers for their CAE analyses. More powerful computers equate to “more robust simulations, more optimization runs, and more detailed models,” Dr. Kohler says. And all of those elements make for better quality cars.

The company realized early on the importance of simulation-driven design for designing increasingly complex vehicles in a reasonable amount of time. “Today CAE has become an indispensable part of modern development processes for us,” Dr. Kohler says. “Our so-called ‘Digital Prototype’ has been integral to the work of Mercedes-Benz Cars Development for over a decade now.”

This article is based on HPCwire’s ISC Keynote Preview: Why Mercedes-Benz Uses HPC. Read the full Q&A to learn more!