Engineering that famous green and yellow quality? The secret is simulation at John Deere

There is something about a John Deere tractor. It certainly has personality. Maybe it is the familiar green color with those catchy yellow rims that make it instantly recognizable? Maybe you cut the lawn summer after summer riding on your Dad’s beloved John Deere? Maybe the farmer down the street had one?

Whatever the case, one thing is for sure. Those John Deere tractors are a constant in the world of lawn care and farming. A farmer’s best friend ready to go from sunrise to sunset – that is pretty much what a John Deere tractor is known for. Quality and reliability, year after year, season after season.

So how do you make sure as an engineer that this is the case with every single tractor model? Especially when your facility makes about 40,000 green and yellow beauties annually.

(Side note: this article only talks only about the agricultural 6000 and most 5000 models shipped globally from John Deere Werke Mannheim in Germany. Which brings about an interesting question: how many tractors does John Deere make a year? We couldn’t find the figure, can you?)

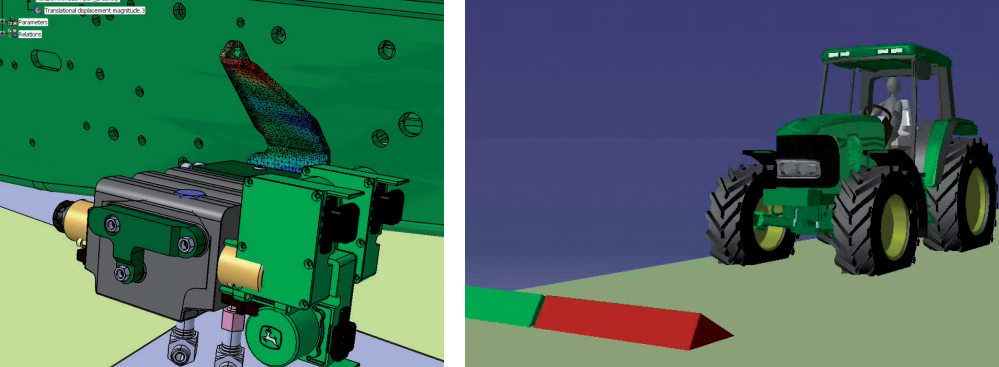

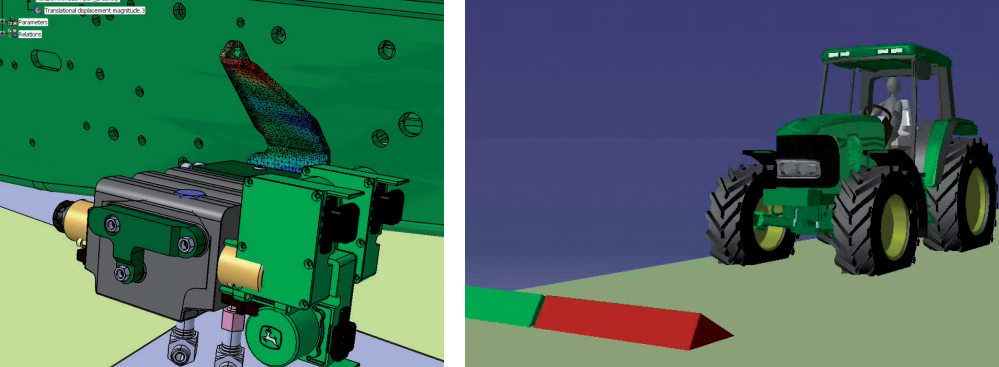

Needless to say, engineering all this quality and reliability is a pretty big job. So we asked Christian von Holst, senior engineer at John Deere Werke Mannheim about their simulation strategies in the form of LMS Virtual.Lab Motion software and LMS Virtual.Lab Durability software from Siemens PLM Software.