Master your mission: De-risk spacecraft qualification

Dynamic environmental testing plays a crucial role in the qualification and acceptance of space hardware. Whether it’s a single component or an entire spacecraft, thorough testing is necessary to ensure that the equipment can withstand the extreme conditions of space and perform its mission without compromising sensitive instruments. This rigorous approach is key to helping de-risk spacecraft qualification. In this blog, we will explore the different types of dynamic environmental testing and how a complete space engineering testing solution provides a comprehensive suite for conducting these tests.

The importance of dynamic environmental testing

Spacecraft are widely acknowledged as fragile and expensive constructs. Throughout their planned missions, they are exposed to the most extreme conditions. Consequently, it is crucial to conduct comprehensive testing on the entire spacecraft prior to its launch into space, as repairing any damages becomes extremely challenging. This rigorous pre-launch testing is absolutely essential to de-risk spacecraft qualification. The purpose of dynamic environmental testing may vary depending on the mission objectives. For standard commercial missions, the focus is on verifying the spacecraft’s performance and preventing degradation of sensitive instruments. However, for manned spacecraft or vehicles, the priority shifts to preserving human life. Therefore, it is essential to subject space hardware to rigorous testing to ensure its reliability and safety

Sine and random vibration testing

Sine vibration testing is one of the primary types of dynamic environmental tests. It exposes space hardware to the low-frequency dynamic launch environment and verifies its performance under these conditions. To accelerate the testing process, engineers need a closed-loop control solution specifically designed for swept sine vibration tests. Only a complete solution ensures safe testing by protecting the hardware from unrealistic failures caused by unrealistic boundary conditions. Such technology combines force and response-limiting techniques to conduct vibration tests in a safe and controlled manner. It allows for the realistic notching of spacecraft resonances and the limitation of acceleration responses to protect the structure and hardware, all of which are crucial steps to de-risk spacecraft qualification.

Random vibration testing is commonly performed for subsystem and component levels of assembly. Space engineers require a solution that provides the necessary features to define and control a random vibration excitation that matches a predefined power spectral density profile. That solution should cover mechanically transmitted energy due to vibroacoustic excitation in the mid-frequency range and offer response-limiting and sigma-limiting features for reliable and safe testing. These capabilities are equally important to de-risk spacecraft qualification at the component level

Shock & pyroshock testing

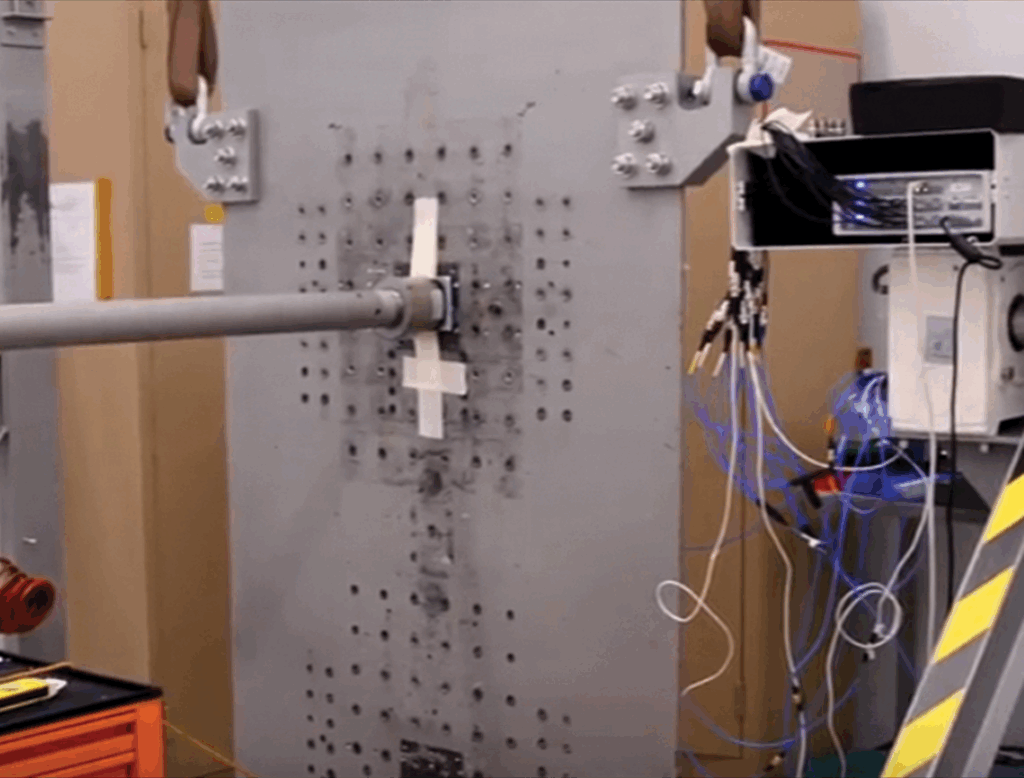

Shock testing, another key way of performing dynamic environmental testing, is essential to assess the capability of space hardware to withstand and operate in induced shock environments. Space engineers require a time-domain control package that enables the replication of short excitation pulses to mimic shocks. This package should incorporate a specialized algorithm for limiting the shock response spectrum, ensuring optimal protection for the test specimen. Additionally, it should offer a diverse range of capabilities for post-test data analysis, all of which are vital to de-risk spacecraft qualification.

Pyroshock, also referred to as pyrotechnic shock, is the dynamic structural impact experienced when an explosion or collision takes place on a structure. It is a crucial event that space hardware must be able to endure. To gather data from transient events like pyroshock explosions, drop tests, or shaker-controlled tests, engineers require a comprehensive testing solution. This solution should cater to the data acquisition requirements of both self-induced and externally induced shock tests, offering triggered and continuous acquisition modes, thereby playing a critical role in de-risk spacecraft qualification.

Acoustic testing

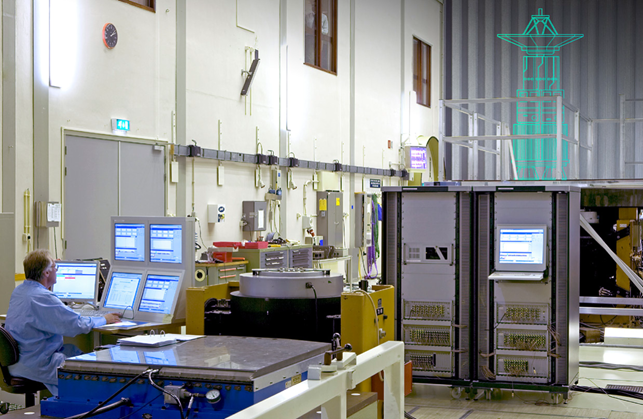

Acoustic testing is a crucial part of spacecraft assembly, with system-level testing being required. However, lower-level acoustic testing is typically done for larger components and subsystems. The challenge lies in accurately replicating the acoustic loads that can cause structural damage and jeopardize the functionality of instruments and subsystems. State-of-the-art testing methods use reverberant acoustic fields to address this.

Engineers need a closed-loop control solution specifically designed for operating reverberant rooms. This solution should have a robust control algorithm based on measurements with standard microphones. It should ensure spatial uniformity of sound pressure levels and incorporate safety checks. This user-friendly system should allow lab engineers to conduct satellite qualification for acoustic loading, which is essential to de-risk spacecraft qualification.

Only a state-of-the-art solution offers features like defining reference profiles, selecting specific microphones, and setting abort parameters. It can work with multiple signals to drive different power amplifiers. While automatic control is the default mode, manual control can be used when needed to adjust voltage levels precisely. These advanced capabilities further contribute to de-risking spacecraft qualification.

Direct field acoustic noise (DFAN) testing, an idea to conduct acoustic testing using loudspeakers, which are traditionally performed in expensive and scarce facilities, is really gaining momentum. You can learn more about it via my previous blog. This innovative approach also aims to de-risk spacecraft qualification by making acoustic testing more accessible and efficient

Multi-axis vibration testing

Recent advances in vibration testing have highlighted the benefits of multi-input multi-output (MIMO) shaker control, which enables simultaneous excitation along multiple axes to more accurately reproduce real-world operating conditions. Traditional single-axis, sequential testing methods often fail to capture the complex, coupled vibrations that occur in service, leading to incomplete fatigue assessments and overly conservative test durations. This enhanced realism is crucial to de-risk spacecraft qualification.

MIMO control addresses these limitations by allowing synchronized, multi-directional inputs that better reflect how products actually experience vibration. As testing standards evolve, particularly in aerospace and defense, MIMO techniques are increasingly being adopted to enhance realism, efficiency, and reliability in qualification and durability testing, paving the way for faster and more representative product validation. These advancements are pivotal for de-risking spacecraft qualification.

Furthermore, the 2306 release of Simcenter Testlab significantly advances shock and vibration qualification by introducing full MIMO shock-control capability that enables realistic replication of complex multi-axis shock events starting from shock-response-spectrum (SRS) specifications. It offers both time-domain control algorithms and waveform-replay modes, as well as an “Undertesting Avoidance Factor” to guard against under-testing in critical frequency bands, and a “Damped-sine Envelope” component type that ensures zero residual displacement/velocity at test end to protect the shaker hardware. Such comprehensive features are instrumental in de-risking spacecraft qualification by ensuring thorough and safe testing.

As a result, test engineers gain far greater fidelity in replicating seismic, blast, or crash-like impulses, multi-axis motions, and cross-correlated waveforms, while streamlining setup, enhancing safety of both the device under test and the excitation system, and improving representativeness of environmental qualification campaigns. Ultimately, these improvements are designed to significantly de-risk spacecraft qualification.

Virtual shaker testing

Designing and executing qualification tests for spacecraft is an endeavor with challenges. Unexpected behavior, under or over-testing, and the sheer difficulty of replicating precise reference profiles can lead to costly delays, potential damage to invaluable hardware, and significant budget overruns. But what if you could mitigate these risks before the physical test even begins, a critical step to de-risk spacecraft qualification?

Enter the “virtual shaker approach”. This groundbreaking technique, which uses Simcenter Testlab RT, allows engineers to create real-time virtual models of spacecraft structures and their test environments. By virtually executing tests beforehand, we can meticulously select optimal parameters, conduct critical sensitivity studies, and ensure hardware protection long before it ever touches a physical shaker table, all of which directly contribute to de-risk spacecraft qualification.

This isn’t just about efficiency; it’s about mission assurance. The virtual shaker method dramatically improves safety, enhances cost-effectiveness, and prevents catastrophic test failures or damage to your precious spacecraft. It’s a game-changer for accelerating the testing of design variants and ensuring your spacecraft is truly ready for the rigors of launch and space, thereby significantly helping to de-risk spacecraft qualification.

Want to learn more?

If you’d like to deepen your expertise in advanced vibration and environmental testing, consider joining the three-day, in-person Siemens Advanced Environmental Testing Master Class—a comprehensive program designed for aerospace, defense, automotive, and marine engineers seeking to master cutting-edge methodologies for qualifying products in demanding vibration environments.

ADVANCED ENVIRONMENTAL TESTING MASTER CLASS 2026

Join us February 10-12, 2026, for this in-person learning event in Leuven, Belgium

Simcenter: A comprehensive approach to de-risking spacecraft qualification

Simcenter portfolio, part of the Siemens Xcelerator business platform, provides a comprehensive suite of software and hardware solutions for dynamic environmental testing of space hardware. These solutions have been developed based on years of expertise and feedback from leading companies in the space industry. They comply with spacecraft testing standards and offer general safety features. Simcenter integrates seamlessly with Simcenter SCADAS hardware, allowing for the measurement of hundreds of channels and providing live feedback on vibration and acoustic response.

Advanced technologies like Virtual Shaker Testing—which can be explored in our master class—enable engineers to safely conduct mission-critical qualification tests, efficiently interpret large data sets, maximize return on investment, and rapidly deliver the right answers to engineering teams. By leveraging these advancements, it is possible to transform space engineering and enhance the overall efficiency and effectiveness of operations, ensuring success in space endeavours.