Cardinal uses Femap API customization to reduce modeling and analysis time by 80 percent

Cardinal Engineering is an engineering services firm providing services to government and commercial clients with a primary focus on the marine sector. The company’s expertise includes naval ship design and analysis, naval power and energy systems, and ocean energy technology development.

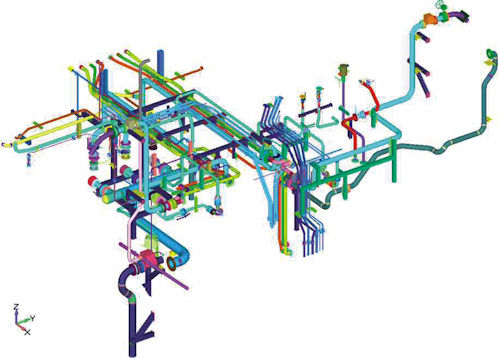

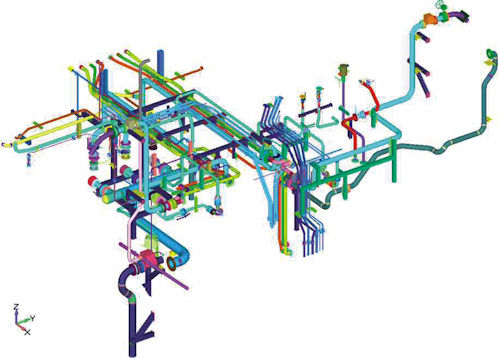

A major challenge for one of the projects the company was bidding on was to demonstrate to the customer that the analysis and documentation of over 1,000 unique shipboard pipe hanger foundation designs could be completed within a very short six-month timeframe. The scope of the work included reviewing the technical data for the pipe hangers and piping systems, developing FE models, conducting analyses, identifying failed foundations, redesigning the hangers and submitting formal reports documenting the analysis work.

Cardinal’s key to success on this project was an innovative methodology developed for meeting the aggressive time schedule, and leveraged the power of the Femap API to achieve that. Cardinal’s strategy was to automate and streamline finite element modeling, analysis and postprocessing to actually perform a full in-depth analysis on each hanger foundation minimizing the use of manpower to perform the 1,000 independent analyses. The application of custom tools enabled Cardinal to reduce the time taken for FE model development and postprocessing by a factor of at least ten.

You can read the full case study and see how Cardinal achieved this significant reduction in modeling and postprocessing time. Also, you can read the Femap Symposium presentation delivered by Dr. Chris Maires of Cardinal Engineering on the subject of Postprocessing using the Femap API.