The fast and the obvious – battery pack thermal simulation

Will “Fast & Furious 15” have the same appeal if the roar of the movie series muscle cars is replaced with a silent “whizz”?

Perhaps not for the purists, but as the electrification of transport becomes ever more ubiquitous, so who knows?

Today, vehicle electrification represents one of the major pillars to help reduce the overall greenhouse gas emissions from human activity. From the early days, there’s been a lot of effort to reduce the overall cost of the battery pack and increase its energy density. Above all, this was essential to offer commercially competitive electric vehicles (xEVs), compared to conventional internal combustion engine (ICE)-based vehicles. It was critical to reduce the consumer’s range anxiety, or in simple terms, remove the fear of being flat in the middle of the Mojave Desert.

Meanwhile, while these initial challenges are on the verge of being solved, engineers now focus on the ability of a battery pack to charge as quickly as possible, also known as fast-charging. In addition, new international regulations are being introduced to standardize the batteries safety rules. The aim is to avoid the catastrophic failure known as thermal runaway, whereby the failure of a single battery cell may lead to the entire vehicle catching on fire.

This leads the vehicles makers to focus even more their effort on the battery pack thermal management system. In particular, engineers need to decide how it should be sized and designed to withstand the challenging conditions of fast-charge and how it could mitigate a thermal runaway event to allow sufficient time for passengers to exit the vehicle safely (in case of an accident).

The value of battery pack thermal simulation

Thermal management of the battery pack is not a new thing. Since the beginning it has been critical to ensuring the battery operates in safe temperature ranges, maximizing its performance, minimizing its degradation, and avoiding any hazardous conditions. Simulation is playing a critical role in this process.

For the simulation to be valuable, the key is in the ability of the models to predict the cell’s heat generation rate with reasonable accuracy. Thanks to this, engineers can identify temperature gradients and hot spots during the battery’s duty cycle. This allows engineers to select the most appropriate cooling strategy, such as air cooling, liquid cooling, or phase-change material cooling. But it also helps to size the thermal management system and refine its design.

Simcenter STAR-CCM+ has been a pioneer since the early 2010s with the release of its capability to perform battery pack cooling coupled electro-thermal simulation with an accurate 3D equivalent circuit model. It computes a 3D distribution of the heat generation enabling the identification of cell temperature gradients and hot spots with great accuracy.

Battery Thermal Management – a bunch of new challenges

Fast forward to 2021, the race for vehicle electrification is real, and many OEMs are developing more and more new electrified vehicle models. They must go fast, adapt their design to the many varying models, and leverage design exploration to optimize each cooling system. They need to evaluate the battery pack thermal and electrical responses over many duty cycles. And finally, validate its integration in the entire powertrain.

But too often, OEMs are only relying on a simple source term for the battery pack temperature prediction, due to an overly complex workflow to achieve a coupled electro-thermal simulation. This may lead to substantial mispredictions in the temperature gradients and limits the ability to assess the battery performance in transient duty cycles. This implies the battery pack will be inefficient, supply less useful energy and degrade faster.

To help address the above challenges, Simcenter STAR-CCM+ 2021.3 is releasing a new batteries workflow that is up to 10 times faster than the original one released in the early 2010s. Its setup is also much simpler and leverages the latest Simcenter STAR-CCM+ technologies in terms of HPC and design exploration.

It offers:

- A super-fast 0D equivalent circuit model for the cell electrical and heat rate prediction

- The support of user-designed CAD of the entire pack including cells for greater geometry flexibility

- A dedicated setup panel for improved productivity

These combined improvements make it obvious that pack cooling simulation should be driven by a coupled electro-thermal approach. Less time spent by the user on pre-processing, thanks to a powerful configurator giving more time to spend on the analysis.

Fast battery charging cycle simulation

Let’s pick the example of an EV battery pack that we need to cool for a fast charge cycle. We will consider a pack with the following characteristics:

| Pack capacity | 79,8 kWh |

| Pack layout | 38 modules in series |

| 3 blocks in parallel/module | |

| 4 cells in series/block | |

| Number of Li-ion cells | 456 |

| Pack weight | 445 kg |

| Nominal cell voltage | 3.6 V/Cell |

| Nominal pack voltage | 532 V |

| Capacity per cell | 50 Ah/Cell |

| Module capacity | 150 Ah |

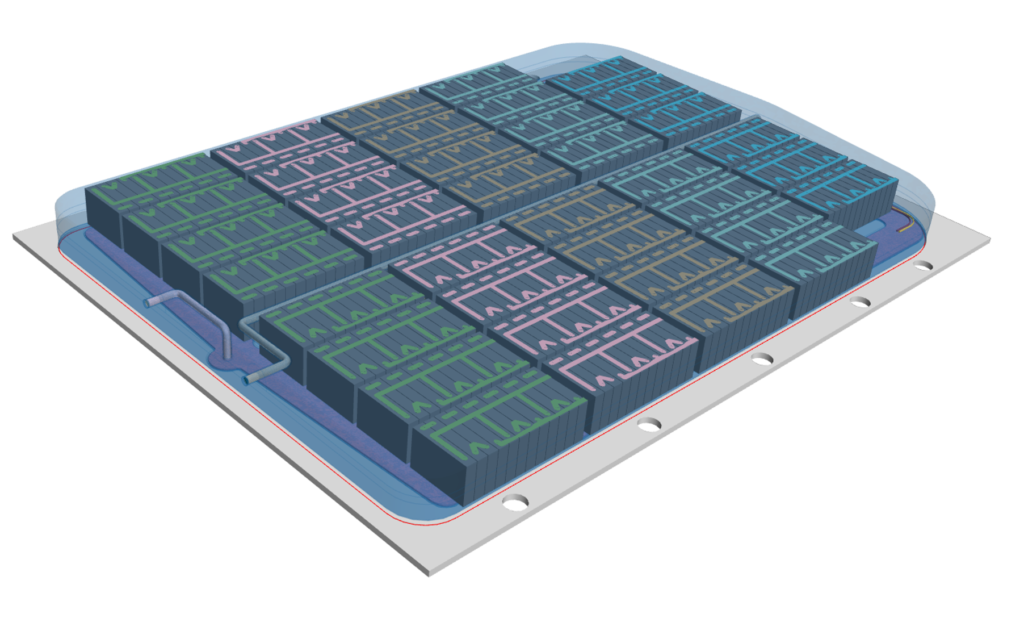

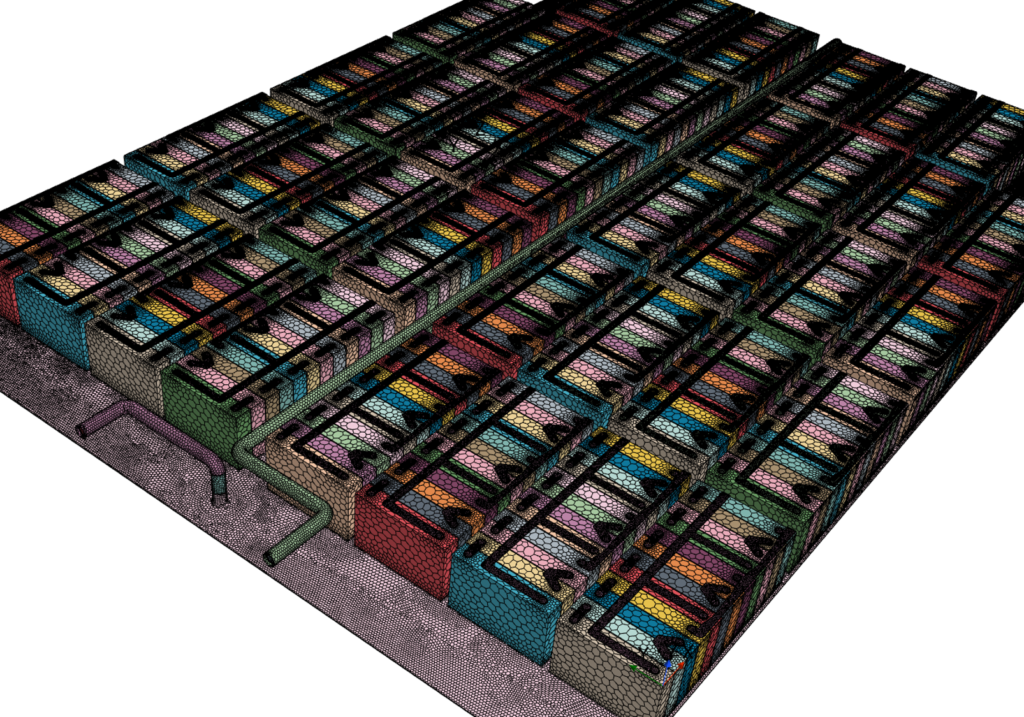

This is a ~80 kWh battery pack, with 456 Li-ion prismatic cells, cooled with a liquid cooling plate at the base.

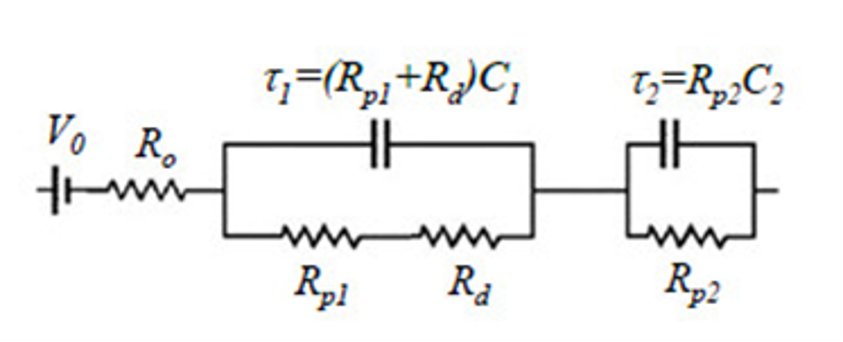

The equivalent circuit model (ECM), with 2 RC elements to better capture diffusion effects, predicts the Li-ion cell electrical behavior. It contains 8 temperature levels from -20oC to 60oC for accurate temperature dependency estimation. The model outputs the cell’s heat generation rate, voltage, current, and State of Charge (SOC).

Fast setup of battery pack thermal simualtions

The user interface dedicated to batteries in Simcenter STAR-CCM+ contains the entire ECM configuration.

Assigning the ECM to the geometry parts for the cells is easily done with the dedicated configurator. The mesh is straightforward and executed rapidly with the parallel mesher, obtaining 6.6M finite volume elements.

Fast insights from battery pack thermal simualtions

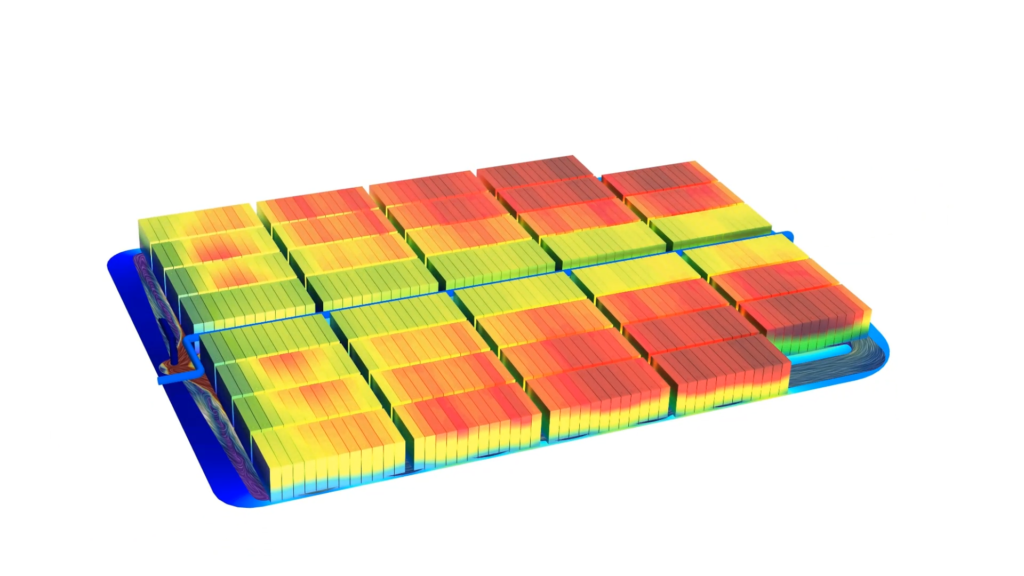

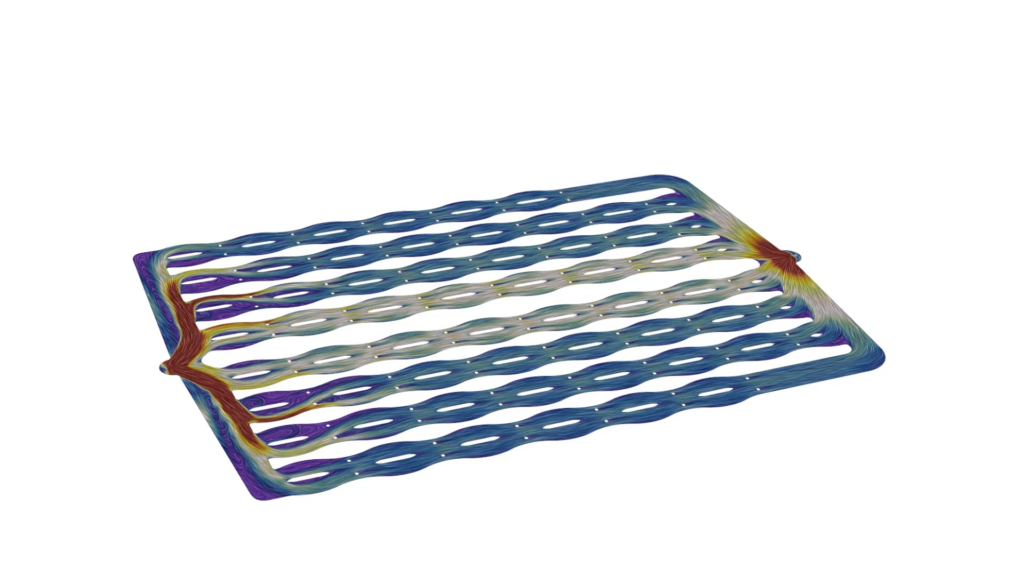

Applying the fast charge at 150 kW for 20 min, the battery heats up non-uniformly. This is due to the imposed high current and inefficiencies in the cooling plate. However, the maximum cell temperature remains under the safety limit of 45oC, which is a typical maximum value.

In less than 2 hours of computation time executed on a computer cluster with 128 cores, the 20 min fast charging duty cycle has been simulated.

The following temperature distribution can be observed on the battery pack and cooling plate:

Battery Themal Management CFD, fast and obvious

With this rapid detailed information, you can now easily analyze the inefficiencies and perform geometry or condition changes to improve the ability of this pack to withstand fast charging

Simcenter STAR-CCM+ 2021.3 makes it “fast & obvious” to enable 3D electro-thermal simulation for battery pack thermal management design.

Efficient, long-lasting, and safe, the batteries designed with Simcenter STAR-CCM+ 2021.3 will please the vehicle OEMs and their customers. For smoke, fire, and explosions, directors of “Fast and Furious 15” will probably have to look beyond the battery packs for the audience’s excitement.

Read more about all top new features of Simcenter STAR-CCM+ 2021.3