Optimizing cardboard packaging for sustainability: A Simcenter HEEDS design exploration

This blog explores how Siemens’ advanced simulation and optimization tools—Simcenter HEEDS, Simcenter 3D, and NX CAD—can be used to design more efficient, sustainable cardboard packaging. By simulating real-world stress tests and optimizing key design parameters, the study demonstrates how even well-established packaging formats can be improved. The result: stronger, lighter, and more cost-effective packaging solutions that align with both sustainability and business goals.

Cardboard’s role in sustainable packaging

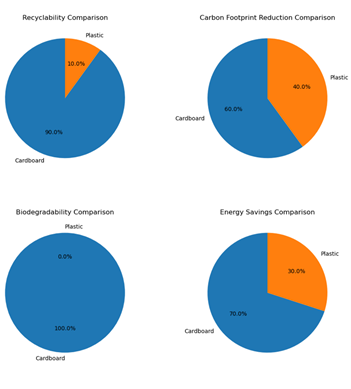

In today’s fast-paced, consumption-driven world, packaging plays a crucial role in how products are delivered, stored, and perceived. However, the environmental impact of traditional packaging materials, especially plastics and excessive paper usage has become a growing concern. As both industries and consumers seek greener alternatives, cardboard has emerged as a leading solution in the shift toward packaging sustainability.

Cardboard packaging helps reduce reliance on plastic and multilayered paper products. Unlike plastic, which can take centuries to decompose, cardboard is biodegradable and widely recyclable. By replacing plastic wraps, bubble mailers, and foam inserts with corrugated cardboard and molded pulp, companies can lower their use of non-renewable materials and simplify recycling for consumers.

Comparing cardboard and plastic packaging

Cardboard’s lightweight nature is a key advantage. Compared to heavier materials like wood or rigid plastics, cardboard reduces shipment weight—lowering transportation costs and carbon emissions. This is especially important in e-commerce, where shipping efficiency directly affects both sustainability and economic performance.

Cardboard is typically made from renewable resources such as wood pulp from sustainably managed forests or recycled paper. Many manufacturers now incorporate high percentages of post-consumer recycled content. Innovations in design—like foldable structures and minimalistic packaging—further reduce waste and resource use. When managed properly, cardboard supports a circular economy where materials are reused, recycled, and reintegrated into production.

Testing and optimizing cardboard packaging with Simcenter HEEDS

Cardboard packaging must undergo a variety of strength tests to ensure it can withstand the rigors of transportation, storage, and handling. These tests usually include but not limited to:

- Edge crush test: evaluates the material’s ability to resist crushing under pressure

- Compression test: Measures the ability of packaging to withstand forces that compress it, ensuring it can handle stacking and storage.

- Drop test: Assesses the durability of packaging by simulating impacts from drops, ensuring it can protect contents during handling and transportation.

- Tensile test: Measures the strength of packaging materials by pulling them until they break, ensuring they can withstand stretching forces.

- Vibration test: Evaluates the packaging’s resistance to vibrations during transit, ensuring contents remain secure and undamaged.

While these tests are essential for validating packaging performance, optimizing the design to meet these standards efficiently is where advanced tools like Simcenter HEEDS come into play. Simcenter HEEDS is a powerful design exploration and optimization platform that enables engineers to automatically explore a wide range of design variables—such as material thickness, flute type, and structural geometry—while considering multiple performance criteria.

By integrating with simulation tools, Simcenter HEEDS can evaluate how different cardboard designs perform under simulated test conditions, helping engineers identify the most effective and sustainable solutions. This not only accelerates the design process but also reduces the need for physical prototypes, saving time, cost, and material waste.

Ultimately, Simcenter HEEDS empowers packaging designers to create cardboard solutions that are not only strong and reliable but also optimized for sustainability and economic efficiency.

Methodology and optimization approach

In recent years, there has been a growing interest in optimizing cardboard packaging design, driven by the dual goals of enhancing structural performance and sustainability. Pyr’yev et al. (2024) developed a model to predict box compression strength, targeting solid cardboard optimization. Fernandes et al. (2022) used fuzzy logic to streamline manufacturing by reducing folds while maintaining structural integrity and quality—enhancing both efficiency and design.

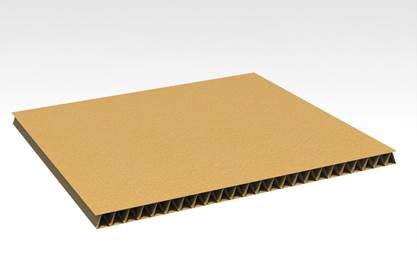

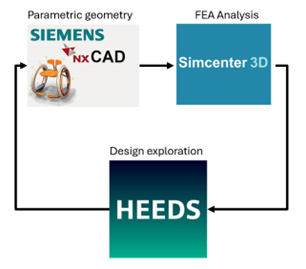

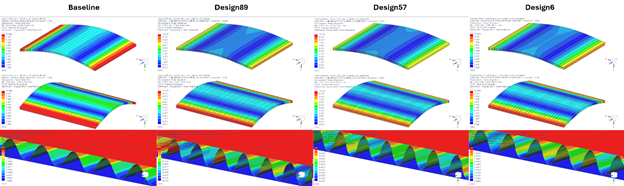

In this study, Simcenter Engineering Services integrated the finite element simulation tool Simcenter 3D with Simcenter HEEDS. We simulated a single-layer cardboard structure under two different loading scenarios using Simcenter 3D. Using Simcenter HEEDS, we optimized various design parameters, including flute thickness, liner thickness, and flute shape, to achieve the goal of reducing material usage without compromising strength and durability.

The optimization workflow proceeds as follows: A parametric, single-layer cardboard geometry model was first developed using NX CAD. This model is governed by parameters such as flute thickness, liner thickness, and two additional variables—height and ratio—which define the flute shape. Based on this CAD model, a finite element model was constructed in Simcenter 3D.

The fluting and liner materials were modeled with elastic orthotropic properties, meaning their strength and stiffness vary depending on the direction of the force—just like cardboard, which is stiffer along the grain and more flexible across it. The orientation of these material properties was based on reference data from A.C. Gilchrist (1999).

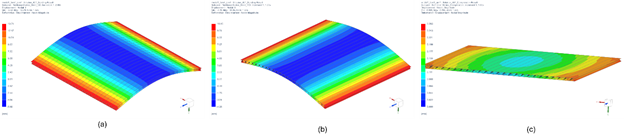

Two testing scenarios were simulated:

Bending tests in two principal directions:

- Machine direction (MD): where the cardboard exhibits higher stiffness and strength.

- Cross direction (CD): where the cardboard is generally more flexible and weaker.

These tests evaluate the bending rigidity of the cardboard.

Flat crush test: This simulation assesses cardboard’s compressive strength.

The parametric finite element model was then imported into Simcenter HEEDS to explore optimized design configurations. This optimization problem involved two primary objectives:

- Minimize deflection under both bending and flat crush tests, as lower deflection indicates greater structural strength.

- Reduce the total weight of the cardboard, aiming to lower material usage and cost.

The optimization process began with a Type C single-wall flute as the baseline design. This choice posed a significant challenge, as Type C flutes are already considered highly optimized and are widely adopted in the packaging industry.

Arriving at an optimal solution

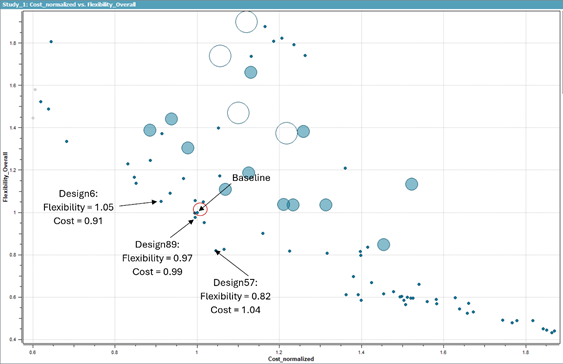

After evaluating 100 design variations, Simcenter HEEDS generated a Pareto front—a visual representation of the trade-offs between two key objectives: maximizing cardboard rigidity and minimizing material cost. Each point on this curve represents an optimal design where improving one objective would require compromising the other. In the 2D plot, each design is shown as a circle, with larger circles indicating higher overall performance rankings.

The baseline design (Type C flute) holds the top rank (Rank 1), serving as a strong starting point. However, several alternative designs demonstrate notable improvements:

- Design 89 refines the structure by reducing flute thickness, increasing liner thickness, and modifying the flute shape to be taller and denser. This configuration reduces cost by 1% while improving rigidity by 3%.

- Design 57 increases cost by 4% but delivers a significant 18% gain in rigidity, making it suitable for applications where strength is prioritized over cost.

- Design 6 achieves a 9% cost reduction at the expense of a 5% decrease in rigidity, offering a more economical option with acceptable performance trade-offs.

These results highlight the essential balance between cost-efficiency and mechanical performance, a key consideration in engineering design optimization.

Extending optimization to other packaging materials for sustainability

While this project focused on cardboard, the same approach can be used for other materials like molded pulp, bioplastics, flexible films, and layered packaging. With tools like Simcenter 3D, Simcenter Amesim, and Simcenter HEEDS, engineers can simulate how these materials behave, test them under real-world conditions, and improve their designs. This flexibility helps companies create new, eco-friendly packaging that meets changing regulations and customer needs.

Final thoughts

This study shows how using computer simulations can help improve cardboard packaging designs for sustainability. By combining tools like NX CAD, Simcenter 3D, and Simcenter HEEDS, we created a flexible model, tested it under realistic conditions, and explored many design options to find the best balance between strength and cost.

Even designs that are already widely used—like the Type C flute—can be improved by adjusting certain features. For example, Designs 89 and 57 demonstrate how small changes in shape and thickness can lead to better performance or lower costs.

Simcenter tools made this process easier by allowing smooth transitions from design to simulation, accurately modeling cardboard behavior, and automatically testing many design possibilities. This helped us find better solutions faster and with fewer physical prototypes.

At Siemens, our Simcenter Engineering Services team helps customers get the most out of simulation-based design. We support everything from early design ideas and 3D modeling to advanced testing and optimization. Using tools like NX, Simcenter 3D, and Simcenter HEEDS, we offer customized solutions that meet your goals for performance, sustainability, and cost. Whether you’re improving packaging strength, reducing materials, or speeding up development, our experts are here to help you succeed.

References

- Pyr’yev, A., et al. (2024). A semi-empirical model for predicting compressive strength in solid cardboard packaging.

- Fernandes, L., et al. (2022). Application of fuzzy logic in optimizing cardboard packaging design and manufacturing.

- A.C. Gilchrist (1999). Nonlinear Finite Element Modeling of Corrugated Board.

Links to Resources

- Simcenter HEEDS – Learn more about Siemens’ powerful design exploration and optimization platform: Simcenter HEEDS | Siemens Software

- Simcenter 3D – Explore the integrated CAE solution for advanced simulation: Simcenter 3D | Siemens Software

- Siemens Engineering Services – Discover how Siemens can support your simulation and design optimization needs: Engineering Services – Siemens Global

- Sustainable Packaging Trends – Stay informed on the latest innovations in eco-friendly packaging: