Efficient Rebase For Long Life Products

Save time and reduce risk of errors with rebasing options for your long life products.

Many industrial products today have long operational lifetimes, I’m talking about lifespans of 10 to 20 or even 30 years, and in some industries, 40 to 50 years. Many of these assets were designed in accordance with standards that have now been replaced. Some were designed to adhere to operating regulations that no longer meet today’s requirements. In most cases regarding these long life products, suppliers or manufacturers who own these product designs are continually working on ways to improve them, and improve the next generation of the product. In the same sense, operators will need to make important decisions regarding product life – upgrades and configuration changes, vs. full asset replacement.

With Teamcenter Service Lifecycle Management (SLM) and its Rebase capabilities, manufacturers and operators can easily analyze their options around long life products, and make smarter business decisions regarding them. For example, long life product operators can work in Teamcenter to update the product’s current physical asset configuration (or definition) to that of a proposed upgrade. First, this will help the operator identify if the upgrade is applicable, and/or if it will require multiple upgrade packages. Second, they can get a feel for how much work is required as the Rebase process will show which parts can stay, which parts need to be removed, and where the new parts need to go to complete the configuration change. And last, using Rebase features, they can validate the parts after the upgrade to see if they match, or highlight the parts that deviate from the desired end state.

Teamcenter SLM to manage long life product configurations

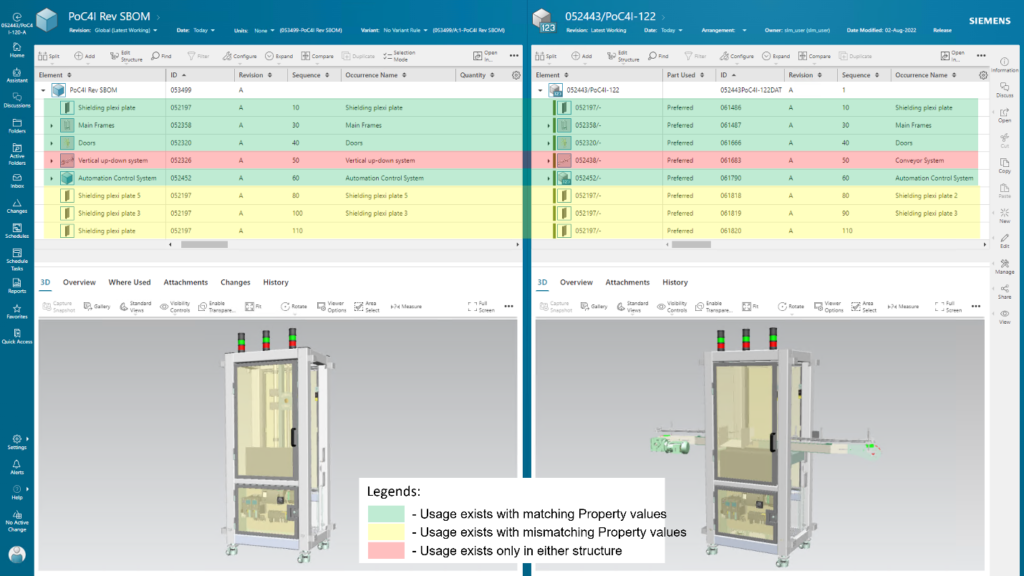

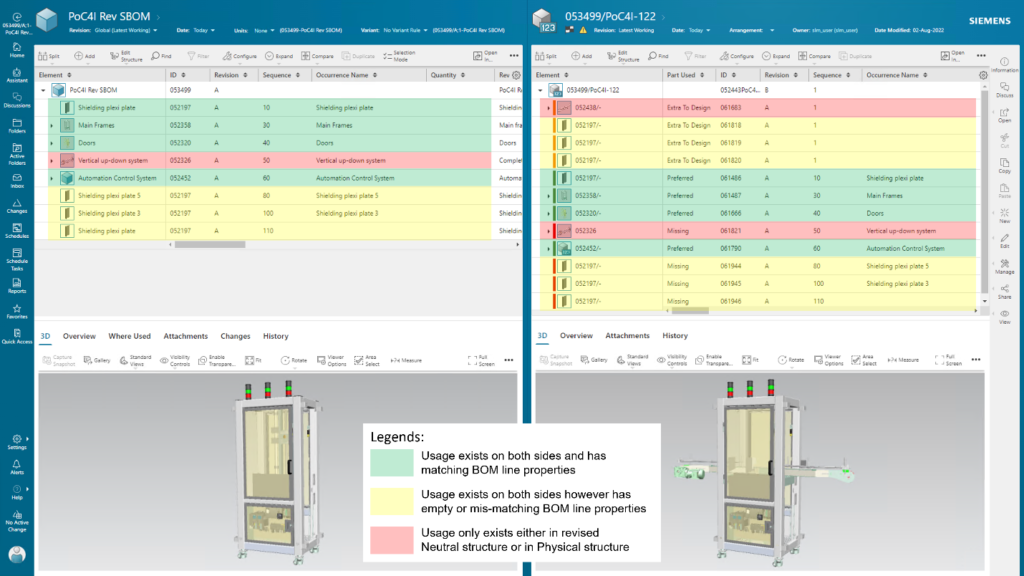

Rebasing a physical asset definition relates the as-maintained structure in Teamcenter SLM to a different configuration of a neutral structure. The new rebased structure uses the new configuration for its structure context.

A rebase can be performed on any level within the physical and corresponding neutral structure. As a quality check, some scenarios, as shown below, require acknowledgement to proceed.

- Neutral part is different from the selected physical part. For example, rebase the old Automation Control system to the new, redesigned Automation Control system, which has a different part number

- Occurrences between the selected neutral and physical part are different. For example, rebase the left wheel occurrence to the right wheel occurrence

Sometimes there is a need to rebase parts from one structure to another. Common parts between the two structures could have different properties because of occurrences. If that is the case, users can set a Preference in Teamcenter that will use a list of properties to identify matching BOM lines between these structures. Aligning parts based on occurrence properties helps to establish uniqueness of matched pairs.

Rebase capability honors common parts found in both structures while highlighting parts that need to be removed and parts that need to be installed to complete the transition from the old part number to the new part number. The following applies to usages in the rebased physical configuration:

- Rebasing from one part number to a different part number, behaves similar to rebasing from one revision to another revision of the same part number

- If the component exists in the rebased neutral structure with matching property values, the rebased physical part is assigned the same usage as specified in the neutral structure

- Part is the same in both configurations

- If a component exists in the rebased neutral structure with mismatching or empty property values, the usage of the same in rebased physical part is set extra-to-design with no deviation authorization required, also a new usage of the physical part is assigned and is set as missing

- Indicating that the part needs to be physically moved to the new location

- If the corresponding usage of a component is not present in the rebased neutral structure, the usage of the rebased physical part is set to extra-to-design and requires no deviation authorization

- Simply remove this physical part to resolve

- If the component and usage is new in the rebased neutral structure, the usage of the physical part is set to missing

- Need the new physical part installed here

Uninstalling extra-to-design and installing missing parts within the rebased Physical structure updates the current physical asset configuration to that of the proposed upgrade.

The following demonstration shows the Rebase process using the Teamcenter Service Lifecycle Management solution.

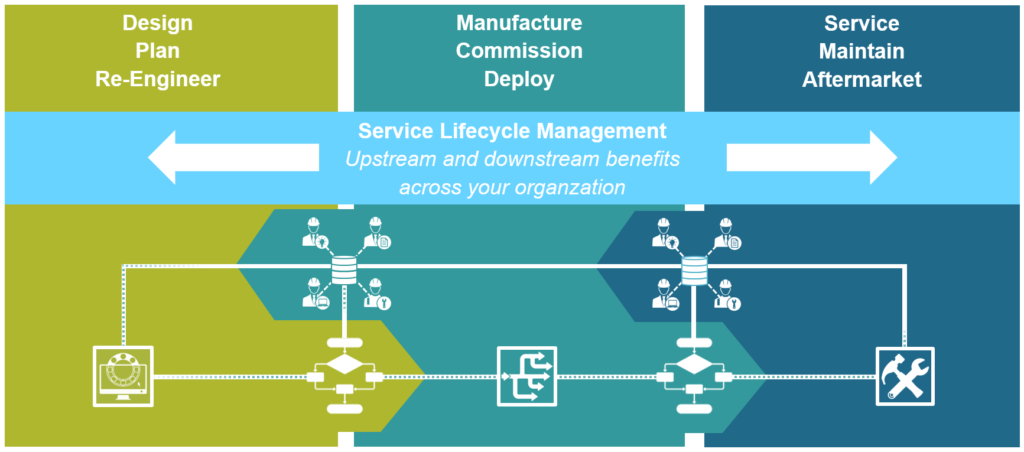

Digital Twin for Service

Our approach focuses on delivering a truly comprehensive Digital Twin that accurately manages physical asset configuration details and provides capabilities to properly contextualize all required data. Asset configurations are linked and continually validated against specifications to ensure quality and compliance. This allows for maximum reuse of all available asset data – whether it’s utilization, analytical models, service requirements, planning, instructions, etc., to provide full traceability and history across various stakeholders.

Learn More

Try Teamcenter Service Lifecycle Management for free, start your 30-day software trial

For a complete list of Service Lifecycle Management virtual seminars and dates, go here

Read more blogs about Service Lifecycle Management