Leverage service data to drive technical documentation

This is the fourth in a seven-part series where we will discuss our integrated Service Lifecycle Management (SLM) capabilities and the potential benefits that can be realized.

If you missed the previous parts, please find them here:

Part 1: Digitalization Strategies for Service Lifecycle Management (SLM)

Part 2: Improve Serviceability with integrated Service BOM Management

Part 3: Reduce Downtime through Accurate Service Planning

Challenges and Pain Points

Knowing that technical documentation is critical to your service operations, how much thought have you put into improving your processes? Are there techniques and tools available that could help your technical publications team create and update the documentation in-line with engineering changes and service data? Is that team fully leveraging the information available to them to decrease cycle times and increase effectiveness?

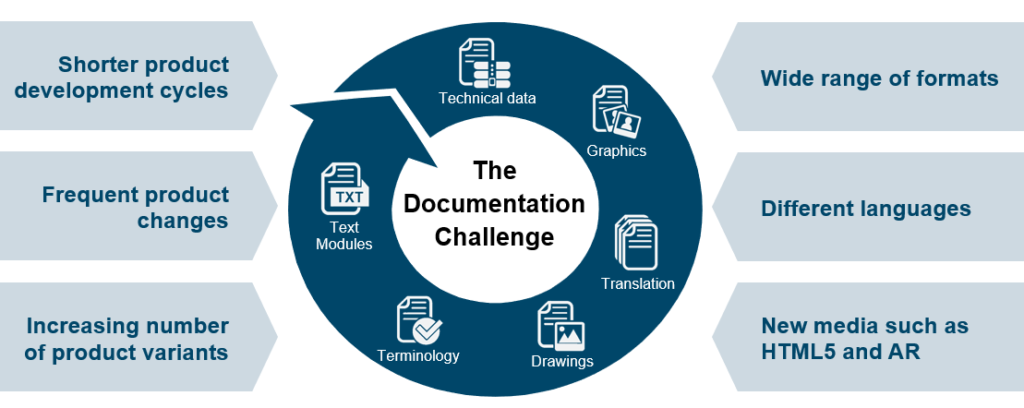

Common challenges faced by many tech pubs organizations includes:

- Longer authoring & update times while product cycle times are shortened

- Delays in communicating Engineering changes

- In-effective documentation with disconnects between the text, 3D & 2D geometry

- Redundant effort in creating multiple output formats (e.g. PDF, HTML, HTML5 and AR)

Further exacerbating these challenges are the fact that many companies typically use several different authoring tools to create the various topics and graphics needed for technical documentation. These tools can include text editors (typically XML editors), additional disconnected 2D and 3D illustration editors, training creation tools, Augmented Reality editors, etc. This is further complicated by the fact that information created for one set of documentation, such as service instructions, cannot easily be leveraged to create another set of documentation, such as training.

These issues are likely creating significant delays, errors, and rework during the creation of your technical documentation.

A Different Approach

The goal is to empower your tech pubs team to address the challenges described above. This can be accomplished by enabling the team to leverage engineering, manufacturing and service data that already exists within your Teamcenter PLM system. Furthermore, your tech pubs team can also directly participate in engineering change processes being managed within the PLM system, making updates timelier and more effective.

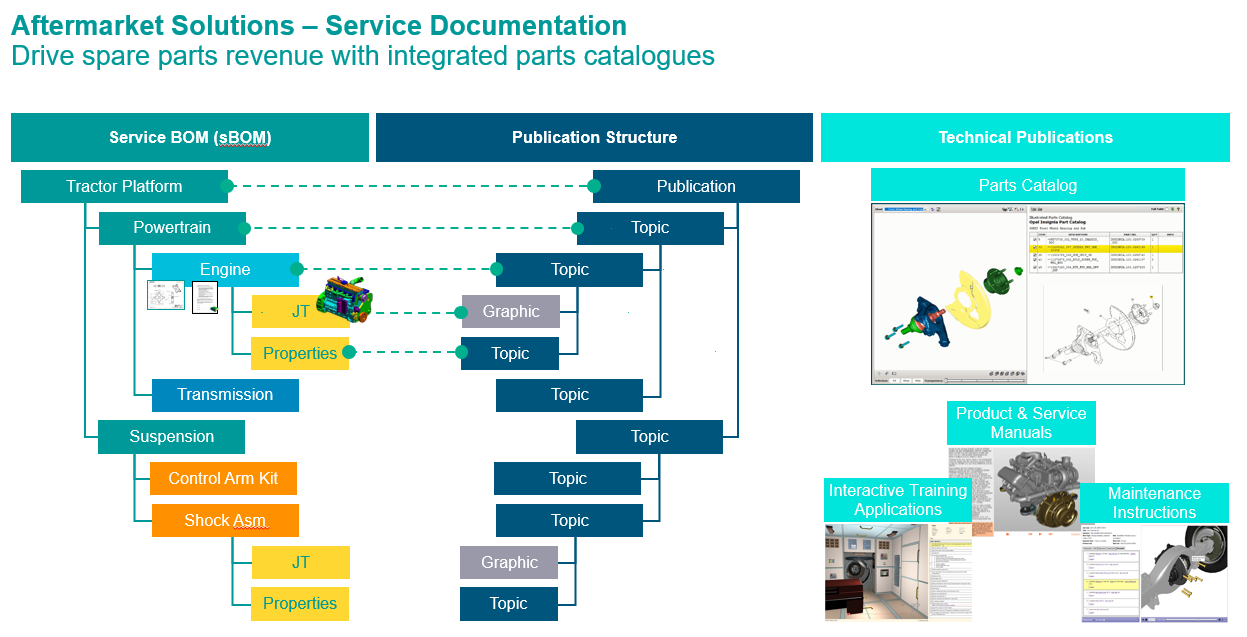

Leveraging the engineering information starts with implementing an integrated Service Bill-of-Material (BOM) that is directly linked to the engineering BOM. This provides a clear & accurate understanding of what parts and assemblies are required to be documented (fig. 2 below).

From a technical documentation perspective, we can also think of a document such as a manual in terms of a “bill of material” – it is composed of the manual, which is composed of chapters (subassemblies) and paragraphs, images, etc. (parts). This represents a Publication Structure, which works in support of content standards such as DITA or S1000D.

By linking the Publication Structure to the Service BOM (which itself is linked to the engineering BOM) you can leverage the existing engineering and service information to drive your technical documentation. No longer are you simply tossing product information ‘over the wall’ to your writers and illustrators. Now you can integrate them directly into the product and service processes resulting in:

- Higher quality deliverables in shorter timeframes

- Configuration driven and configuration specific documentation

- ‘Write once, reuse many’ by supporting standards such as DITA and S1000D

- Publish to traditional formats of PDF, HTML, HTML5 alongside new formats such as Augmented Reality

- Increase Quality & compliance

- Service technicians can access interactive instructions, even when in the field

- Make it easier for your customers to easily find and order replacement parts leveraging interactive, 3D selection tools

Look for part five in the series coming soon where we will discuss our solution for managing physical structures in Teamcenter, providing for accurate as-maintained configuration details of your fielded assets.

Learn more about our Service Lifecycle Management offerings here.