Polarion for Industrial Machinery – Blog series 1/3

In the world of industrial machinery manufacturing, there is one word that can describe the current challenges these companies face: complexity.

This complexity includes a rapidly increasing amount of software required inside machines, competitive globalization, shrinking margins, customer requirements for more customized machines, environmental and government regulations, as well as other smart factory initiatives.

In the face of these pressures, it is clear that machines need to be smarter. If you are unable to address the complexity that comes with adding software to your machines, develop an advanced machine from customer requirements or compete aggressively on a global basis, your days of profitable growth are limited. Essentially, the core requirement is to become more innovative in machine design and operation as well as the development process.

Industrial machinery manufacturers must be able to design, engineer and commission machines virtually in order to optimize performance, improve quality and maximize margins. In doing so, you can also improve the speed and efficiency of the design process chain, increase collaboration across the domains, ensure reproducibility and efficiency of manufacturing processes, and meet regulatory needs with advanced mechatronic design.

To address these challenges, manufacturers need to integrate key digital development aspects such as requirements management, configuration management, change and cost management as well as project management. There is also a need to more effectively define and manage the complex requirements needed early in the design phase, as well as integrate electronics and software into the design.

Blog series

In this blog series “Polarion for Industrial Machinery ” we take a closer look at how Polarion is the key collaboration platform for you to strengthen your competitive position in the market in 3 different areas.

- From customer request to a valid offer

- Cost reduction during commissioning

- Integrated product development

For today’s blogpost let’s kick off with the first one on our list.

From customer request to a valid quote

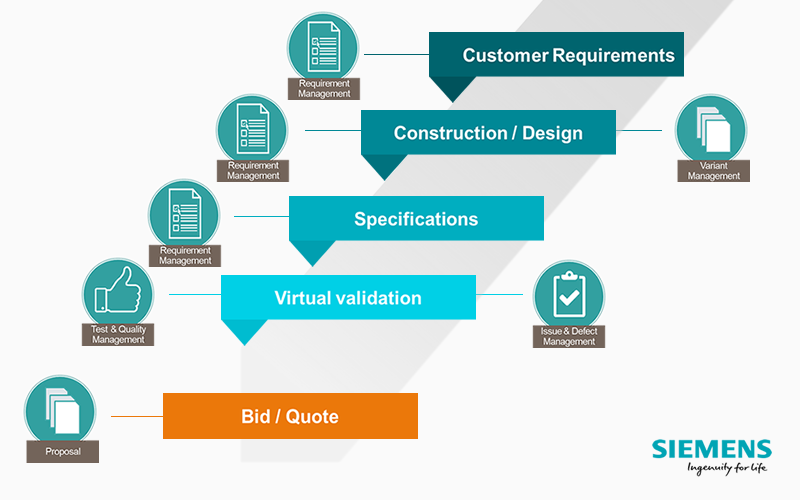

Let’s go thru the process flow from getting the initial request to have a final proposal.

In the 1st phase, you get from your customer the request for a quote – Customer Requirements – than you start to design means construct the building blocks to fulfill the specification based on the customer requirements.

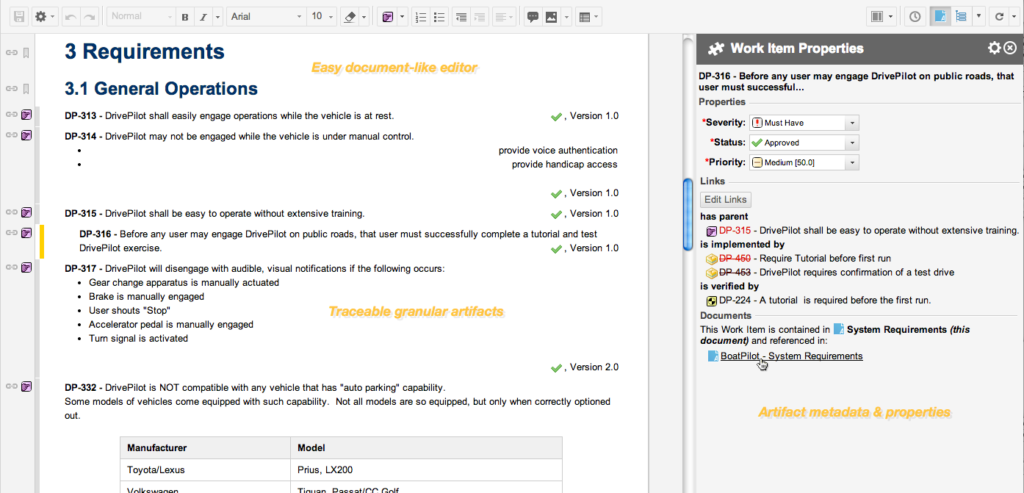

Within Polarion you can easily manage and import (from Microsoft Word for example) these customer requirements within its patented LiveDoc™ functionality. With its “Easy-As-Word” authoring and real-time collaboration, the customer request gets structured in Polarion and stored in the Machinery Library in Polarion. Now the document is ready for use across your entire team to work on the specifications and the quote preparation.

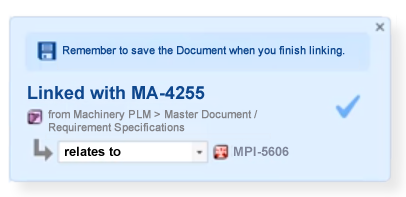

Now you can simply search across your Machinery library and link the specification of an existing machine to your new customer request. With this link, you get all related tests and quality information linked as well.

With Polarion’s Quote Management dashboard, you can see how many customer requirements are standard and how many customer-specific. You can see the summary of the analysis expressed in how many days you need to deliver on the requirements, the split in percentage between customer-specific and standard, as well as all the individual customer-specific unique items. This all gives you a better insight into what load and resources each specification has on your organization, bid/quote, and bottom line.

After these steps and this is really early on in the lifecycle you can start already the virtual validation of your quote, based on the detected requirements, the test cases are considered and first quality check on possible issues & defects on your design/construction can be verified by simulation. With this early on verification, your Bid/quote reaches now a higher maturity level as well as greater confidence in your offer.

By preparing and storing all dedicated machine specifications, configurations, and quotes within Polarion it will greatly improve collaboration and traceability for example on approval processes, reuse across different projects and variants – variants management – and give you a headstart when you actually land the deal.

In summary of the requirement management and bid process, Polarion can manage your customer request with a much more efficient, accurate and competitive quote.

Want to see Polarion for Machinery in action, sign up for a live demo today.