What’s new in Opcenter Execution Pharma 2411

Empower operators with In Process Control and At-line Testing in Operator Cockpit

Summary

Opcenter™ Execution Pharma (EX PH) software serves as the foundation for leading pharmaceutical manufacturers and innovators that want to enable rapid change, lean paperless manufacturing, consistent quality output and higher profit margins. Offering native integration between the manufacturing execution system (MES) and the distributed control system (DCS) layer, Opcenter EX PH expedites the design, execution and review of the manufacturing process steps and provides flexibility in the master batch record (MBR) design process.

Opcenter EX PH 2411, which is a part of the Siemens Xcelerator business platform of software, hardware and services, enables users to regulate and manage processes without paper-based procedures or documents. With Opcenter EX PH, you can easily configure and leverage out-of-the-box (OOTB) functionality to facilitate design processes even if the user does not have specific information technology (IT) skills.

Powered by an advanced workflow engine and easy-to-use electronic work instructions (EWIs), manufacturers can use Opcenter EX PH to direct manufacturing while recording and centralizing everything required for a completed batch record. Further, leveraging MBRs facilitates managing key process parameters.

As the system is fully compliant with U.S. Food and Drug Administration (FDA) and Good Manufacturing Practice (GMP) regulations, manufacturers can optimize batch manufacturing processes and streamline resources such as user guidance, equipment allocation and standard operation procedures (SOPs). The software can also systematically control the manufacturing execution at all stages, including human operations or operations controlled by the automation layer.

Using Opcenter EX PH enables manufacturers to reliably acquire critical process data. Additionally, users can forward and backward search using the genealogy and audit trail tools and review product batch records by exception to provide faster and more efficient product releases. This significantly reduces the manufacturing review and release times and facilitates a faster time-to-market.

Opcenter EX PH 2411 includes several enhancements, delivers new OOTB features, eases the engineering requirements and reduces the total cost of ownership (TCO) of a customer’s system.

Benefits

- Adaptable & extensible operator cockpit via low-code for a tailored best-fit user experience

- Simplified process design and execution for complex cyclic operations

- Embedded quality operations for in process control and at-line testing

- Extended equipment logbook uses cases through configurable attributes

- Integrated manufacturing dashboarding and KPIs

- Support of the latest SIMATIC Batch V10 release

Capabilities

Cyclic operation Packaged Business Capability (PBC)

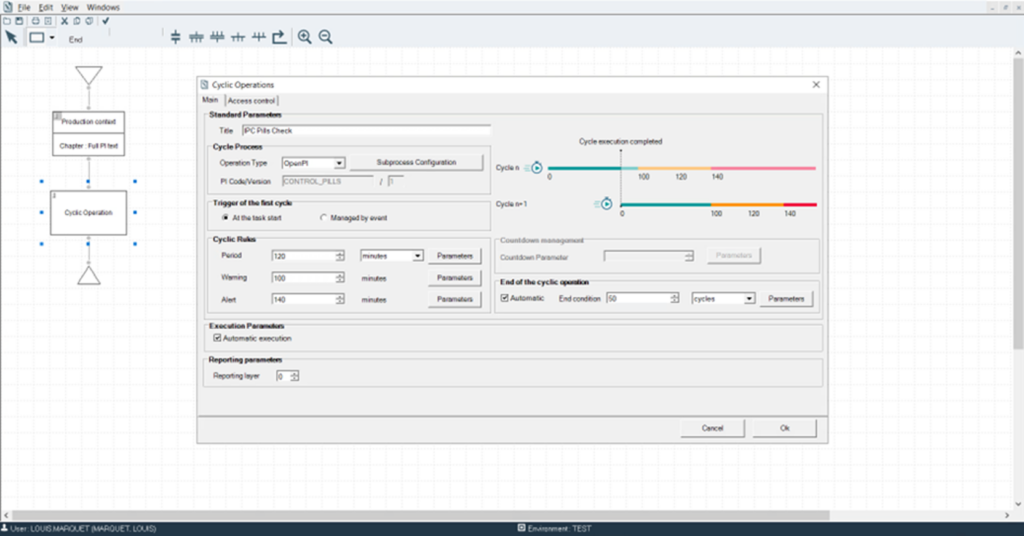

There are several activities the shopfloor operator needs to perform repetitively, such as cleaning equipment and performing quality control. Prior to this enhancement, designing such activities in Opcenter EX PH was sometimes challenging, making operator guidance during execution suboptimal.

With this new Packaged Business Capability:

- Design is intuitive: Cyclic activities are created effortlessly with a single workflow element, specifying related processes, periodicity, and time intervals.

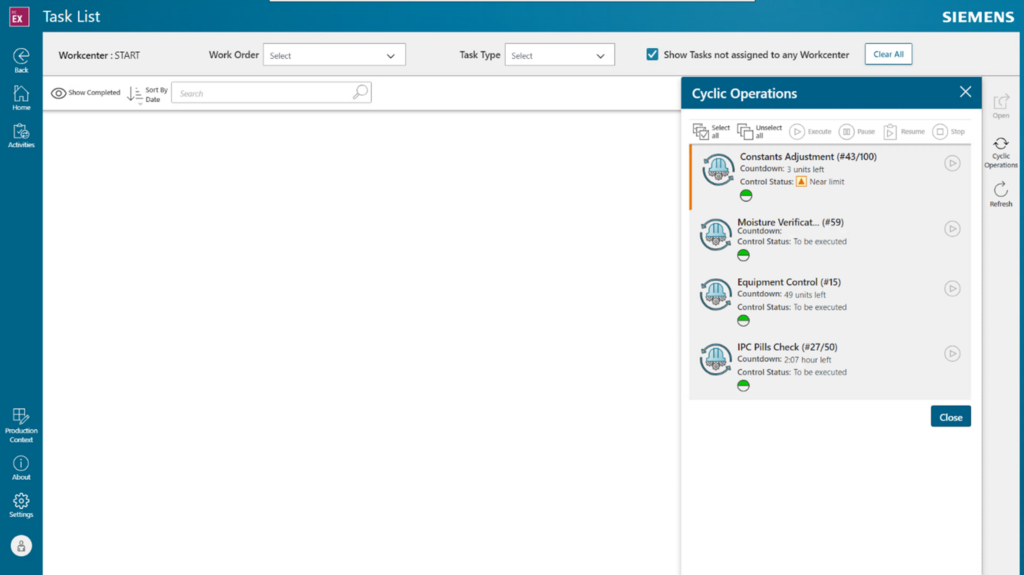

- Execution is easy to monitor and more efficient: A new cyclic operations supervision view is available in the operator cockpit app, showing timers alerting operators to urgent cyclic tasks, ensuring a timely completion.

Benefits:

- Simplified process design

- Best operator UI to monitor, execute and manage cyclic operation

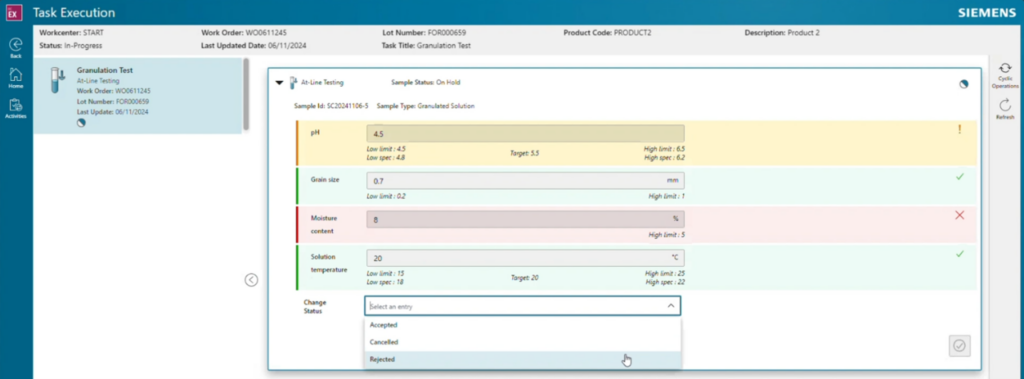

Test execution and verification PBC

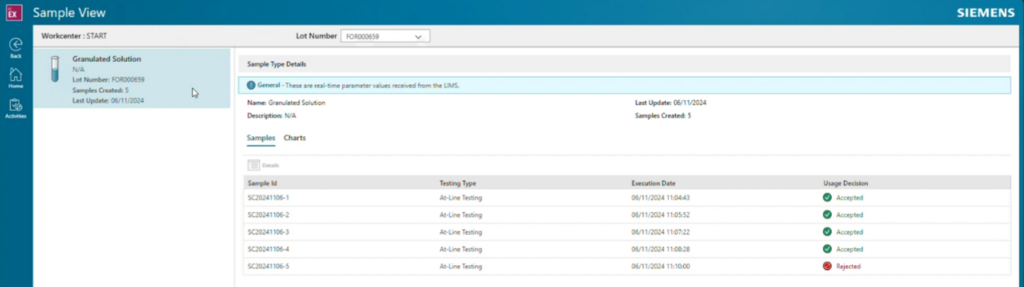

The Test Execution & Verification (TEV) PBC allows the management of integrated quality scenarios within the Opcenter EX Pharma workflow by triggering quality controls at the task level. A new ‘At-line testing’ element is provided in the PI Management workflow engine to streamline sample-taking activities directly from the operator cockpit during execution.

This new at-line testing element leverages seamless interoperability with Opcenter Laboratory.

In-process control (IPC) scenarios can be modeled easily by incorporating a new at-line testing task element into several cyclic operations sub-processes.

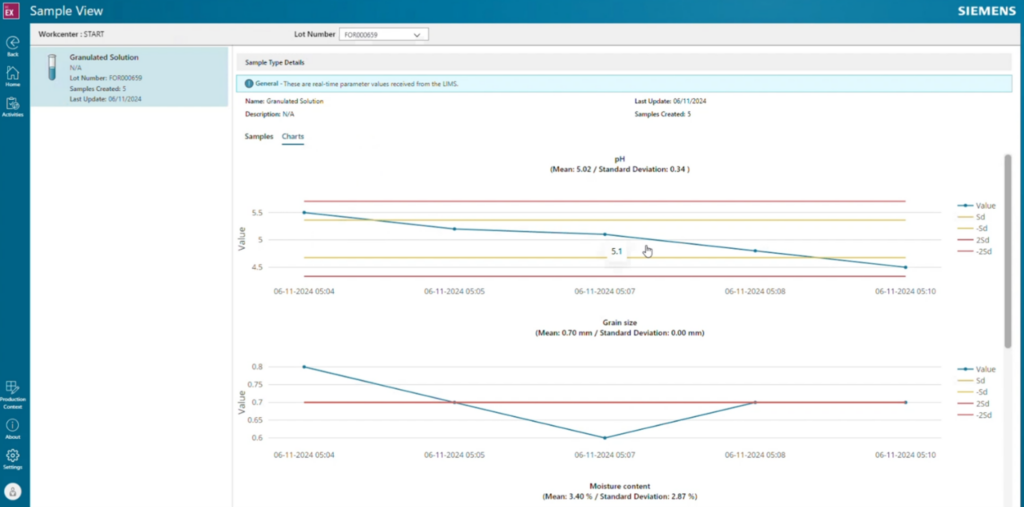

In the new “samples” view of the operator cockpit, detailed charts are provided displaying parameter evolution across multiple quality controls.

Benefits:

- Execution of at-line testing, in process control and all kinds of verifications in the operator cockpit

Operator cockpit enhancements

The application has been enhanced with the following features:

- Local time zone management :

Operators can now set their local time zone. Upon selecting a time zone based on their geographical region, related parameters such as language, date and time formats and numeric character options automatically adjust. Operators can choose default local settings associated with their workstation and user profile. - Mendix embedded with Opcenter EX PH:

Operator Cockpit now includes an automatic installation procedure via a script executed through the Opcenter EX PH scripted installation. - Cyclic operation PBC:

Operators can perform cyclic operations directly from the cockpit. A new dedicated panel enables actions such as select all, unselect all, stop, pause (with a reason for pausing), and resume. - Adaptability features:

Enhancements to improve the operator cockpit’s extensibility paradigm include modular access rights for task execution, a refresh token mechanism and the ability to encapsulate specific web widgets within the application. - At-line testing task execution and sample view:

The application now features a user-friendly interface that enables operators to input sample parameter results while displaying the corresponding tolerance values. Additionally, a dedicated sample view is accessible at any time, providing an overview of the sampling plan process, including the execution status and progression of sample parameters throughout the manufacturing process.

Equipment logbook enhancements

Key updates and enhancements:

- Additional attributes for logbook entries:

Supervisors can now:- Associate specific actions with equipment types, limiting the action options displayed during logbook entry creation.

- Define additional attributes for logbook entries based on the equipment type-action-subAction combination.

- Specify whether these additional attributes are mandatory.

- Ensure attribute names are unique for a given equipment type-action-subAction combination.

- Define these additional attributes via APIs.

- Review enhancements:

- Users can view and review counts per logbook and per location on demand.

- Performance improvements:

- Logbook entry creation has been optimized, reducing the processing time to sub second on large databases.

- The performance of the Logbook Details page loading has been optimized.

- UI-based configurations:

- Environment variables can now be set directly from Opcenter UI instead of the Mendix Service Console.

- Date and time display formats in the UI are configurable.

- Users can adapt the naming style of logbooks created automatically with equipment.

- Miscellaneous updates:

- The login page is updated to align with the latest UX policies.

- An equipment, along with its associated logbook, can now be relocated to a different location.

Benefits:

- Support of additional functional equipment logbook use cases

- Flawless system performance and interaction

Shopfloor integration enhancements

Opcenter now supports the newly released Simatic Batch V10, facilitating seamless project upgrades and enabling the use of the latest enhancements.

In addition, Opcenter batch task element is enhanced to provide formula identification (category, name, version) at the time of the batch creation. Providing the formula identification simplifies the Simatic Batch recipe design as it allows more generic recipes and reduces the effort of design and testing.

Generic recipe features have been extended to support scenarios where batch recipe parameter enumeration IDs have been changed while already configured in the MES workflow, improving seamless integration between the systems.

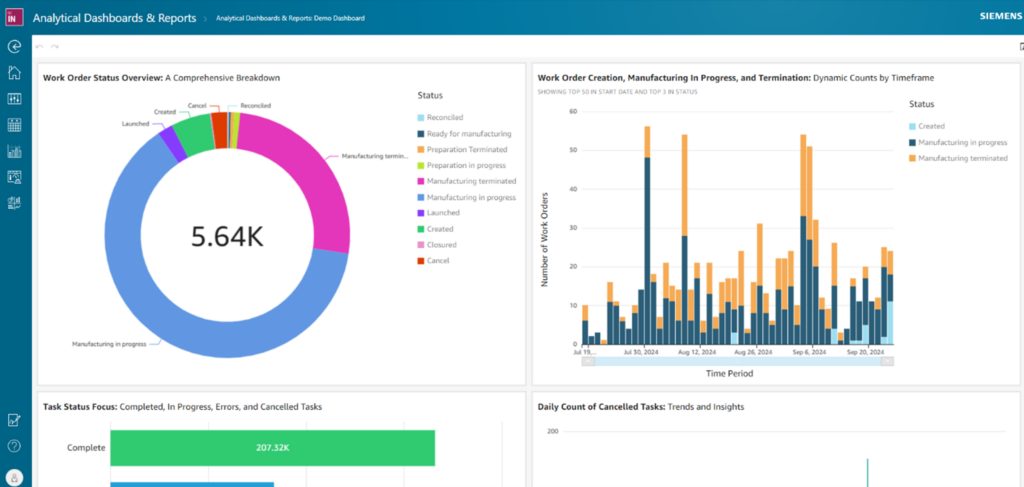

Enabling Opcenter Intelligence capabilities

Opcenter Intelligence is a solution for manufacturing dashboarding and KPIs. Through native connectors for Opcenter Execution Pharma, it enables easy creation of manufacturing dashboards, KPIs, and process analytics.

This integration can be extended further to support additional use cases and custom entities via low code configurability.

Benefits:

- Configurable manufacturing dashboarding and data analytics for Opcenter Execution Pharma

Improved serviceability, supportability and DAID

The .NET Task SDK introduced as technical preview in previous release, is now officially available and supported.

The new .NET task SDK simplifies developing new workflow tasks. It allows integrators to implement new features in the workflow with less code and fewer errors. The .NET task SDK provides the default behaviors of the task (default report, parameters management, etc.) avoiding unnecessary development and focusing the effort on the functional feature.

Using .NET language enables most integrators to implement their new tasks ensuring code quality whilst reducing maintenance and avoiding recompilation of project specific extensions for each new product release.

The .NET task SDK allows to answer complex requirements by providing dedicated UIs to create complex workflows, scripts and operator instructions.

With Opcenter EX PH 2411, the automated installation procedure is enhanced to facilitate the deployment of project specific customizations. These custom developments can now be embedded as part of the standard product deployment scripts to deploy all artefacts at once.

Additionally, Opcenter EX PH now supports PostgreSQL database version 16 in addition to version 14.

Benefits:

- Enhanced and simplified customization capabilities, requiring less effort

- More capabilities to integrate systems and components

Summary of Opcenter EX PH 2411 enhancements

Equipment Logbook App

- Configure additional attributes

- Configure environment constants

- Enhancement of logbook entry review

- Display count of unreviewed logbook entries at Location

- Move equipment

Cyclic Operation PBC

- Cyclic task management engine (time or event based)

- Supervision screen

- In Process Control (IPC)

Test execution & Verification

- At-line testing

- Samples view

- Native interoperability with Opcenter Laboratory

- In Process Control (IPC)

Operator Cockpit App

- Adaptability enhancements

- Locale setting management

Shopfloor integration

- Support of formula

- Generic event from different PCell configuration

- SIMATIC Batch V10 support

Dashboarding via Opcenter Intelligence

Serviceability & supportability

- PostgreSQL 16 support

- Scripted installation extension

This version also includes several upgrades to technical aspects, enhanced security and bug fixes.

Want to learn more?

With Opcenter Execution Pharma Siemens Digital Industries Software has developed a dedicated MES solution for the pharmaceutical industry that enables complete paperless manufacturing and full electronic batch recording.

Opcenter Execution Pharma provides advanced features for designing, streamlining and managing production operations and processes – both manual and automated – via seamless integration between the MES, automation and enterprise resource planning (ERP) systems.

Find out more about Opcenter Execution Pharma.