What’s New in Opcenter Execution Electronics 8.4

Providing the next level of integration with material management and scheduling.

We are excited to announce the latest version of Opcenter Execution Electronics has been released! Version 8.4 is now available.

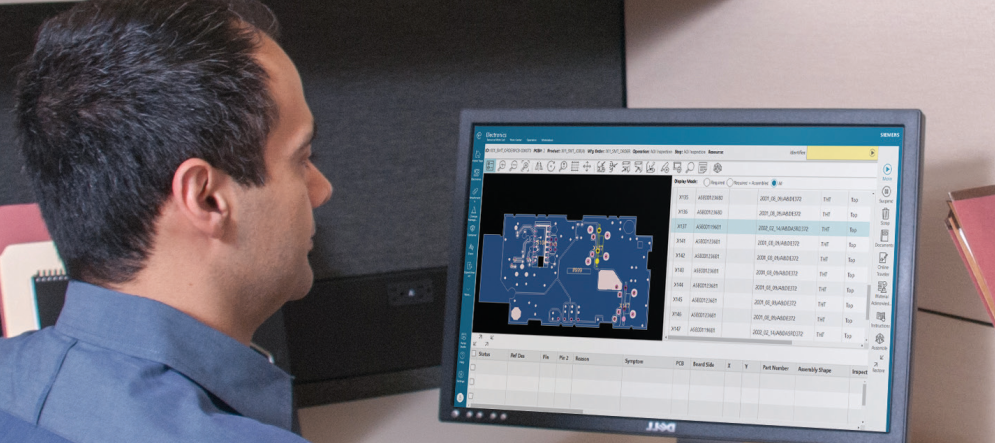

Electronics manufacturers are realizing faster new product introduction (NPI) and time to market, while improving their ability to compete in a rapidly changing, consumer-driven marketplace. Opcenter™ Execution Electronics software is a full digital manufacturing solution for the electronics industry. It is built on the industry-leading manufacturing execution system (MES) platform for the medical device and semiconductor industries. Opcenter Execution Electronics extends throughout the electronics value chain, including printed circuit board (PCB), mechanical and box-build processes.Electronics manufacturers are realizing faster new product introduction (NPI) and time to market, while improving their ability to compete in a rapidly changing, consumer-driven marketplace.

Opcenter Execution Electronics version 8.4 provides the next level of integration with material management and scheduling, enhanced features to con-figure NPI work instructions, and advanced and new operational reports with several usability improvements.

The latest release provides the next level of integration with Material Management and Scheduling. Version 8.4 delivers the following benefits:

Already using the Opcenter Execution Electronics? See what’s new in v 8.4.

- Provide an integrated material process for SMT, THT and box assembly, including stock maintenance for all materials

- Efficient and improved production scheduling for the combination of PCB and box production

- Reduced overlapping configuration in MES and APS

- Improved scheduling results and throughput

- Increased production visibility and quality

- Fewer operator clicks and improved production efficiency

Want to learn more? Opcenter Execution Electronics is a comprehensive manufacturing execution system (MES) for electronic printed circuit board (PCB) and box build. It is designed specifically to help electronics manufacturers respond efficiently to frequent design modifications, short product lifecycles and increased product and production complexities, all while improving quality and reducing the cost of operations. Opcenter Execution Electronics enables PCB and box assemblers to meet traceability requirements, control production, and integrate the shop floor into their product lifecycle management (PLM) and enterprise resource planning (ERP) system. Learn more about Siemens Opcenter Execution Electronics.

Discover how to achieve more with data driven manufacturing – Valor Manufacturing Solutions