Manufacturing Operations Management for manufacturing agility in modern times

With manufacturers seeking new ways to keep staff members separated from each other, the value of Smart Manufacturing takes on an added dimension. Along with raising productivity, efficiency and quality, Smart Manufacturing technologies are more embraced to enhance the health and safety of manufacturing teams. After all, by their very nature digital technologies decrease contact with high-touch surfaces by multiple individuals, enable social distancing (including remote interaction with manufacturing operations), and otherwise hamper virus transmission routes.

While these health and safety benefits are important within each manufacturing enterprise, uncertainties during unprecedented times have raised the importance of other digitalization benefits, making them not just valuable but essential. The pandemic has generated challenges for manufacturers and to the entire supply chain network, that extend far beyond human wellness – challenges that go to the very heart of the manufacturing endeavor, and in some cases, threaten the survival of some manufacturing firms. Manufacturers who produce items that become scarce during a pandemic are struggling to increase capacity. Manufacturers of products for which demand falls or experience supply chain disruptions during a pandemic are struggling to make use of their idle plants and lines.

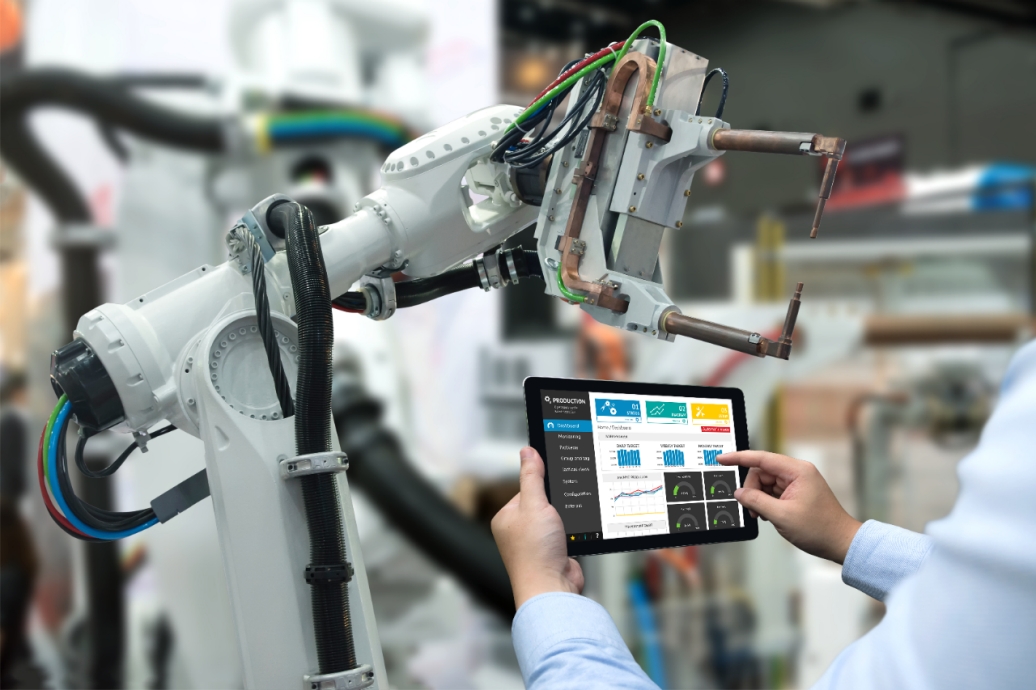

As the manufacturing world steps through the phases laid out for re-opening the economy, per guidelines of local governments of site locations, critical advantages of Smart Manufacturing are especially prevalent. Modernizing systems that support shop-floor processes is critical to realizing the benefits of smart manufacturing. Associated capabilities and technological advancements in Manufacturing Operations Management are critical for digitizing today’s shop-floor operations to create safe, agile manufacturing to build today and tomorrow’s products.

Manufacturing operations management (MOM) – the set of technologies and capabilities that serves as a bridge between a company’s automation systems, which are responsible for actual production (with human in the mix), and its enterprise systems, such as product lifecycle management (PLM) and enterprise resource planning (ERP). MOM is used to orchestrate shop-floor processes for much needed operational transparency, visibility, traceability, quality and continuous improvements.

Let’s look at three key requirements of successful manufacturing under any uncertain market conditions, each of which benefits significantly from effective implementation of MOM technologies for Smart Manufacturing:

(1) optimized manufacturing throughput

(2) manufacturing agility and rapid response

(3) readiness to adopt emerging technologies

Optimized Manufacturing Throughput

Three chief factors are creating intense pressure in managing throughput:

- The dynamic nature of fluctuation in market demand and supply

- The manufacturers’ drive to bring products and innovations to market safely

- The complexity of the new norms for worker safety and product quality

In simplistic terms, manufacturing throughput is measured through operational efficiency and order fulfillment cycle time. Processes are needed to identify and eliminate bottlenecks, but this requires supporting systems that not only provide actionable insights on bottlenecks, but also streamline the improvement areas and optimizations. This requires modernization to digitize shop-floor systems and processes for:

- Management of proactive planning and scheduling with the flexibility to predict and react with known constraints

- Management of manufacturing processes with point of use information for operators, technicians, engineers and other shop-floor personnel; streamlined with information flow across enterprise and automation systems

- Management of quality processes to streamline product and process compliance, quality transparency across departments and processes

- Orchestration of closed-loop processes within shop-floor operations with enterprise (ERP, PLM, SCM) and automation systems in loop for lean and continuous improvements

- Operational intelligence for data driven manufacturing with actionable insights – across shop-floor processes, assets, cross-functional departments or supply chain dependencies

In reality, optimizations are not realized just by streamlining information and data management, but are heavily dependent on the supporting systems’ flexibility and agility.

Agility and Rapid Response

In many industries rapidly changing supply chain dynamics, the escalation of new product introductions (NPIs), and the trend toward mass customization (making individualized products at prices typical of mass-produced goods) were already pressuring manufacturers to accelerate production line changeovers and minimize time-to-market. Global uncertainties magnify these pressures through unprecedented manufacturing changes, epitomized by the adult beverage maker switching to production of hand sanitizer, or the automotive OEM suddenly producing ventilators, or manufacturers trying to rebalance their production across facilities adhering to local demands and compliance guidelines.

MOM systems and associated capabilities bridge the gap between virtual and real production. This means they link functions that previously operated as stand-alone, siloed systems: R&D, design, engineering, planning, production and more.

It also means that MOM enables the agile and rapid responses to change that market conditions, that are demanding for today and readiness for future. MOM’s ability to aggregate, contextualize and orchestrate data from where it is generated to where it is needed means that manufacturers can quickly and efficiently effect production changes through activities such as:

- Designing products that can be manufactured on existing equipment

- Transferring product designs into new production facilities

- Simulating manufacturing performance of those designs

- Retooling existing machines to make different parts and products

- Introducing new production technologies, integrated for data flow and orchestration

- Training and instructing human operators remotely and at scale

- Scaling specialized engineering know-how to less skilled operators

- Laying out new shop floor designs to accommodate new working model requirements

- Accurately forecasting schedules and delivery dates

- Ensuring effective communication, transparency and visibility across supply chain and end customers

- Lastly, delivering point of use information with actionable insights per use role

An integrated MOM enables manufacturers to respond effectively to dramatic market changes through extremely agile and adaptable manufacturing infrastructures that connect the entire IT landscape.

This provides much needed effective and efficient production flexibility, a key ingredient for agility and rapid response that is and will be data driven across the enterprise.

Readiness for Emerging Technologies

Just as manufacturers improved productivity in past decades through innovative automation of manufacturing processes, so today they are leveraging emerging technologies that promise to elevate production even more in the future. Adoption of these technologies is continuously evolving at a rapid pace and has intensified with global uncertainties. This is augmented with the fact that emerging technologies play a key role for adoption rate by next generation workforce and leaders of digital world in manufacturing.

The drive to adopt some of these technologies has intensified under the specter of pandemic. For example, augmented reality and virtual reality (AR/VR) technologies may prove critical to social distancing on some manufacturing floors. MOM capabilities, complemented with other technological advancements, orchestrate the implementation and application of new, innovative technologies within the manufacturing environment. Included among these are:

Advanced robotics and automation where an increasing trend of human-machine collaboration plays a key role in both production throughput and production line changeover. These technologies must be seamlessly incorporated into automated production through the connection and orchestration that MOM capabilities provide.

Augmented Reality – With these technologies, experts working remotely will instruct operators working on the shop floor – by seeing what they see and communicating with them in real time. The scalability and efficiency of expensive, specialized skills can take a huge leap forward. Augmented Reality can be applied for online or remote machine maintenance and repair activities, remote inspections and audits, and complex assembly instructions and data collection and product build issue and non-conformances documentation / resolutions, all with required traceability. Augmented Reality (and Virtual Reality) can accelerate the workforce training and ramp-up period.

The industrial internet of things (IIoT) promises unprecedented connectivity, intelligence and responsiveness of manufacturing operations. A MOM solution is needed to harness the powerful capabilities of IIoT. MOM capabilities complement IIoT capabilities and incorporate IIoT devices and the cloud to enhance global visibility and real-time information for the whole organization, with product, process, machine, and resource context.

Additive manufacturing and 3D printing – These manufacturing technologies have proven their value in recent years, with their ability to quickly change output. As these manufacturing technologies scale from prototype to mass production, MOM capabilities enable design engineers to simulate product performance of different materials, complete product, process, and quality traceability to accelerate changes in the supply chain. As production scales, more of IIoT and cloud technologies are leveraged, MOM functions will add complementary value in collaborative network of AM manufacturers to assess capacities, schedule and trace.

Artificial intelligence and machine learning can be applied to data that is contextualized from the shop floor through MOM functions, creating predictive production, logistics (or supply chain), quality and maintenance insights towards prescriptive process improvements and failure mode corrections. AI-driven dynamic scheduling optimizes a flexible, agile environment for increased responsiveness and throughput.

As manufacturers adopt MOM capabilities for current state digitalization vision and flexibility for emerging production technologies, some critical facets to consider are,

- Modularity in MOM capabilities

- Flexible deployment architecture

- Remote implementation, serviceability & maintainability

The changes to manufacturing operations that unprecedented events have brought about seem unlikely to abate as the situation stabilizes. Manufacturing, we think, will be forever changed. Thankfully, the digital technologies, especially Manufacturing Operations Management from shop-floor perspective, are ready to support that change, helping companies not only to weather the storm, but to emerge on the side with greater agility, responsiveness, and capacity for optimized operations, plus embrace new production and supporting systems technologies.

With Opcenter Portfolio products (as part of Xcelerator), Siemens is not only supporting our customers for today but also bringing tools and technologies to empower manufacturers for tomorrow.