Controlling the 5Ms in Pursuit of Product Quality | Part 4 – Measure

In this blog series, we’ve been getting back to basics. Product quality is rooted in the control of the 5Ms of manufacturing – material, man, machine, measure, and method. If you get those right, your product will be built as designed. While some things never change, like the 5Ms, some things always change, like technology. And today’s Manufacturing Execution System (MES) makes controlling the 5Ms a lot easier than it used to be using paper-based, manual processes.

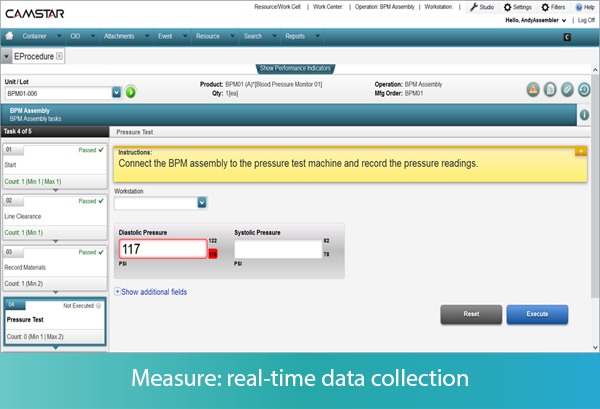

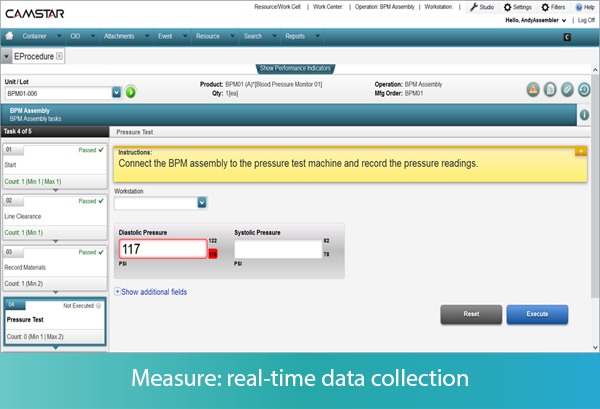

In Part 4 of this series, we discuss the fourth M, Measure. When we think of controlling Measure from an MES perspective, we are talking about measures within the manufacturing process, such as product component size and recipe amounts. There are precise measurements that are defined by the product design, as documented in the SOP.

The MES monitors these measurements, and ensures they stay within specification limits. The MES can also use Statistical Process Control (SPC) to proactively monitor trends that indicate the process is heading towards an out-of-spec condition.

Let’s look at an example. With an MES, the operator is guided through every step of the production process, including steps where measurements are to be recorded to ensure product characteristics are in spec. An inspection screen captures key measures automatically through an interface to test equipment or measurement device, or can be entered manually. When an operator enters the measurement, the MES automatically validates that measurement against the specification. If the measurement is out of the specification tolerances, a visual error message is generated, and the production process for that component or unit is suspended.

Let’s say the measurement is within spec. SPC charts are displayed, such as an X-bar chart, an R Chart, and a Process Capability chart. If an SPC rule is violated, such as 6 points trending in an upward direction, even if the specific measurement is in spec, an error message will be displayed. In addition, the MES can trigger an Out-of-Control Action Plan, or OCAP. Actions can be to place the unit on hold, change thestatus of the piece of equipment from Up to Down, or send an email notification to an engineer or maintenance technician. SPC creates an additional layer of process control enforcement, over and beyond basic tolerance enforcement for measurements.

Today’s MES is helping manufacturers control the manufacturing process through enforcement of correct measure. In addition, the MES tracks all of those parameters. For regulated industries, like Medical Devices, the MES automatically generates the electronic device history record, or eDHR, required for regulatory compliance.

If you are still using paper-based and manual processes to control the 5Ms of manufacturing, your pursuit of product quality remains an uphill journey.

Continue reading about how an MES controls the 5Ms of manufacturing in our next blog, focusing on Method.