Connecting smart machines for holistic closed-loop manufacturing

Manufacturing of industrial machinery is a highly progressive industry with many ongoing trends, such as smart machines. From robotic arms that assemble parts to computer-controlled milling machines that cut and shape metal, smart machines are used to automate production processes and increase efficiency. By connecting smart machines, information can be shared in order to monitor and control operating conditions, as well as ensure quality and identify defects.

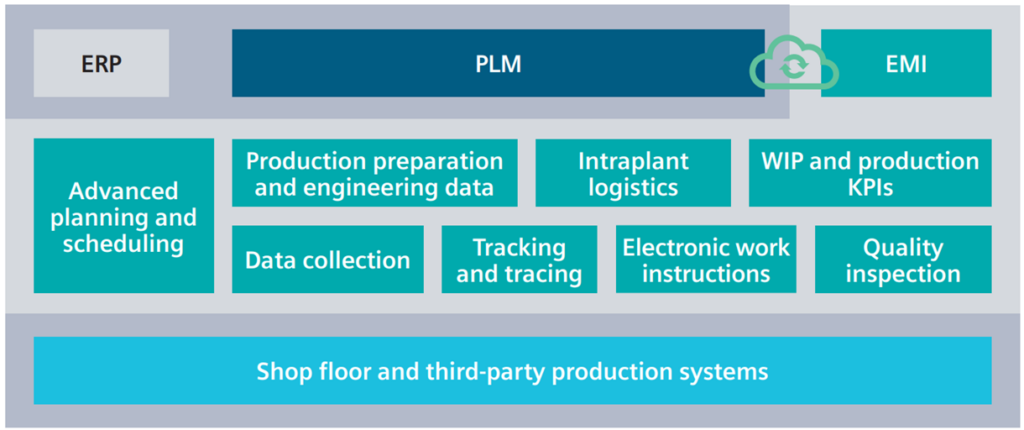

Connectivity between the different machines is just as important as their access to the various data systems in the manufacturing site. The interaction between the ERP system and PLM can build new bridges with the help of the cloud-based EMI,by:

- Collecting data from the developing engineering team

- Linking planning and scheduling with intraplant logistics

- Keeping an eye on KPIs and quality at the end of line

This information enables smart machines to control and monitor the manufacturing process on a new level.

Closed-loop manufacturing does not only deepen the understanding in the manufacturing process but also helps with maintaining a high-level quality management system. The result is seen in a decrease of scrap and defects as well as trained staff which makes sure that the smart machines are working like a well-oiled machine.

If you want to learn more about trends in manufacturing of industrial machinery and how to react to those, check out this infographic below, of which we covered the part of software compatibility in depth.

For more information, you can also take a look at our Ebook on transforming industrial machinery manufacturing with the implementation of Manufacturing Operations Management (MOM).