Opcenter EX Discrete 2407.0001 – Version update

Leveraging out-of-the-box solutions for complex assembly and job shop environments

Summary

Opcenter™ Execution Discrete (Opcenter EX DS) software, which is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services, is designed to meet the needs of industries that execute sequential discrete manufacturing functions, including:

- Automotive tier suppliers

- Aerospace and defense tier suppliers

- Energy and utilities

- Industrial machinery

- Heavy equipment

- White goods and home appliances

- Complex parts manufacturing and assembly

- Additive manufacturing

By using Opcenter EX DS you can leverage specialized out-of-the-box (OOTB) functions for complex assembly manufacturing, job shop environments (high complexity, low volume) and automated repetitive manufacturing industries (configurable products, high volume).

Opcenter Execution Discrete 2407.0001 can be installed directly or as an update.

This release includes:

- Master plan resolution based on unit occurrence effectivity: you can create work orders to produce variants of a product engineered in Teamcenter Manufacturing by creating work orders from master plans based on unit occurrence effectivity. By adopting this approach, during master plan resolution, all elements that do not match the configured unit effectivity will be filtered out. Unit effectivity is managed for work order operations (and implicitly its steps, even if they have a different unit effectivity), operation folders, materials, tools, machines and human resources.

- Material consumption allowed on any MTU revisions: Material consumption is now allowed for any revisions of a to be consumed material. If there are MTUs with the correct revision or different revisions of the same MTU identifier or code, consumption can proceed. If there are no MTUs respecting those criteria, the MTUs are created on-the-fly and consumption is not blocked as well. Now it’s supported of decimal values has been extended to eight decimal digits.

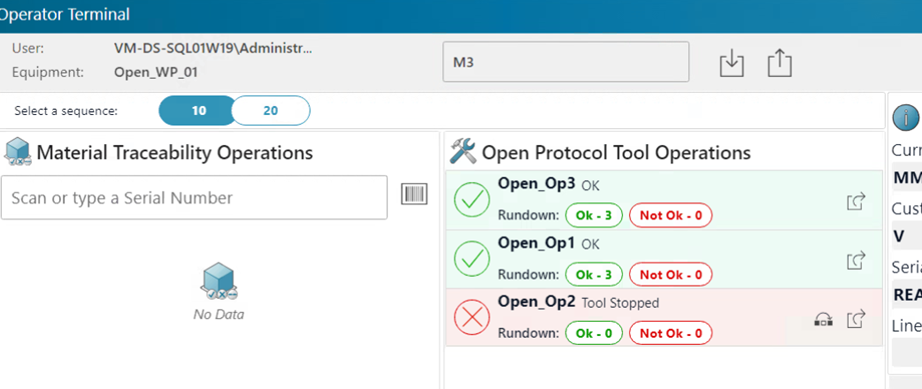

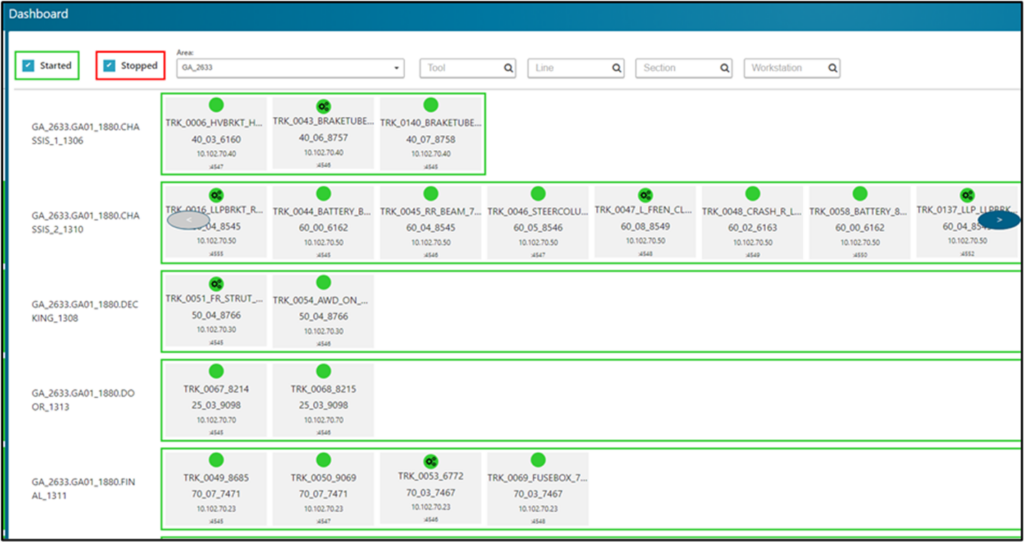

- Open protocol tool management: thanks to the integration with the open protocol service asset, it is possible to use open protocol tools that communicate via TCP/IP with open protocol nodes, in order to register the acquired values and related results, operating in the Opcenter Execution Discrete One Piece Flow low code UI app. Failed or not executed operations can be repaired at the quality gate. In addition, thanks to the integration with Opcenter Connect MOM , both the XML file for importing master plans and the output message (standard and JIT/JIS) include a section dedicated to open protocol operations.

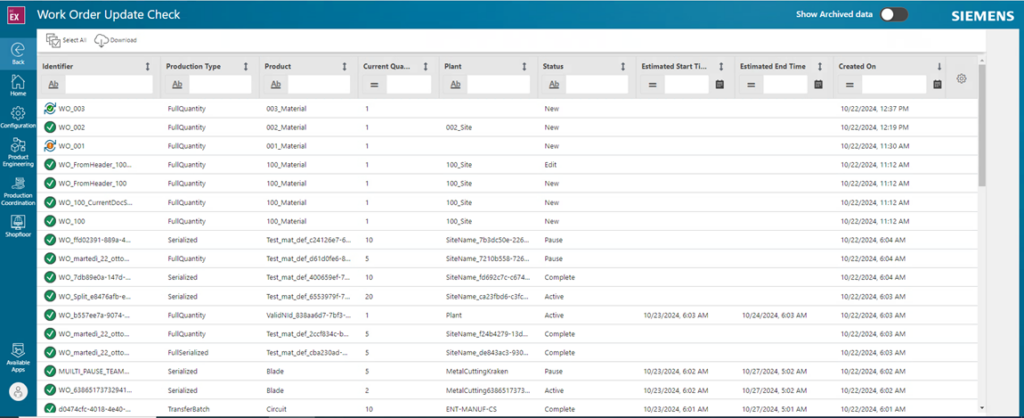

- Update of work orders created from out-of-date ss planned BOPs: As of this version, exclusively in the Opcenter EX DS Production Coordinator App, thanks to the work order update check page, it is possible to check for the presence of work orders created using out-of-date ss planned BOPs and, if deemed necessary, permit their eventual update. In detail, it will be possible to:

- see those work orders for which the latest as planned BOP is available in your system;perform a direct update of those work orders for which the latest as planned BOP is on-board;

- see those work orders for which the latest as planned BOP is not available in your system;

- request a new as planned BOP from Teamcenter for updating those work orders for which the latest as planned BOP is not on-board and successively perform their update.

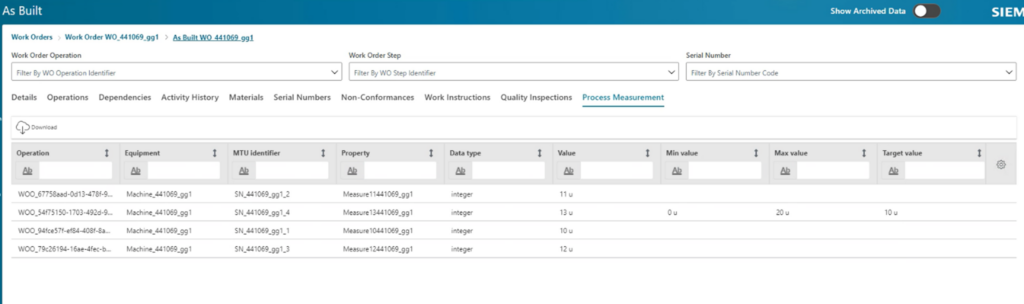

- Process measurements: it is possible to collect a list of measurements, with related actual and thresholds values, in the context of the production of a specific item or without any explicit reference to production items, based only on timestamp.

The measurements have a generic structure, so that it is possible to store in the MES runtime database a generic property without having to necessary design it in the data model.

The measurements which are collected in the context of a specific work 0rder are shown in a dedicated tab in the new Mendix as built UI.

- Document items support: Product engineers and production coordinators can manage Document Items, which are used as containers for documents that share similar characteristics or a common purpose and for which revision management is possible.

By establishing a link between an operation contained in an as planned BOP and one or more document items, it will be possible to aid the operator in the execution of the work order operation that is instantiated at runtime.

Instead, when configuring work orders, document items can be linked not only to work order operations, but also to work order steps.

Learn more about Opcenter Execution Discrete 2407.0001 by accessing Support Center , where both the detailed release notes and the product download area can be found.