What’s new in Opcenter X 2407

Boosting operational success: Empowering operators with essential manufacturing resources

Summary

Siemens Digital Industries Software is pioneering modular MOM, enabling more manufacturers to take a stepwise approach to digital transformation. Built with cloud technologies and offered as software as a service (SaaS), using Opcenter™ X software, which is part of the Siemens Xcelerator business platform of software hardware and services, lowers the time and cost barriers for SMBs, enabling you to realize rapid return-on-investment (ROI) with modules that connect and adapt as your enterprise matures.

With Siemens as your MOM solution partner, you can be sure Opcenter X is built on a rich and deep knowledge base and the extensive capabilities of a leading software company. We listen to and learn from our customers, then innovate and capture best practices for every digital task. Then we apply best practices to accelerate time-to-value of our software.

With Siemens as your software partner, implementing modular MOM capabilities by using Opcenter X will bring about the manufacturing agility you need to thrive in your manufacturing space, both today and into the future.

Benefits

- By adding manufacturing resources like tools to your operations, user can enhance efficiency and productivity. These resources can be easily provided to operators during execution, ensuring that they have everything they need to excel in their tasks.

- Easy adding and access to manufacturing important documents and work instructions

- Configurable gantt chart for easier handling (e.g. display range or filtering)

- Statistical Process Control (SPC) evaluation considers visual inspections

- Effortless quality control integration: Seamlessly insert quality tasks and collect data without any disruptions

- Better shopfloor connectivity through OPC UA and HTTP

Features

- Document and resources management optimization

- Enhanced gantt interactivity

- User defined custom views for scheduling

- Many to many relationship support for scheduling

- Non-conformance management

- Statistical Process Control enhancements

- Process designer

- File connector and Http connector (Opcenter X can call the APIs of external systems)

- OPC UA connector (with some limitations)

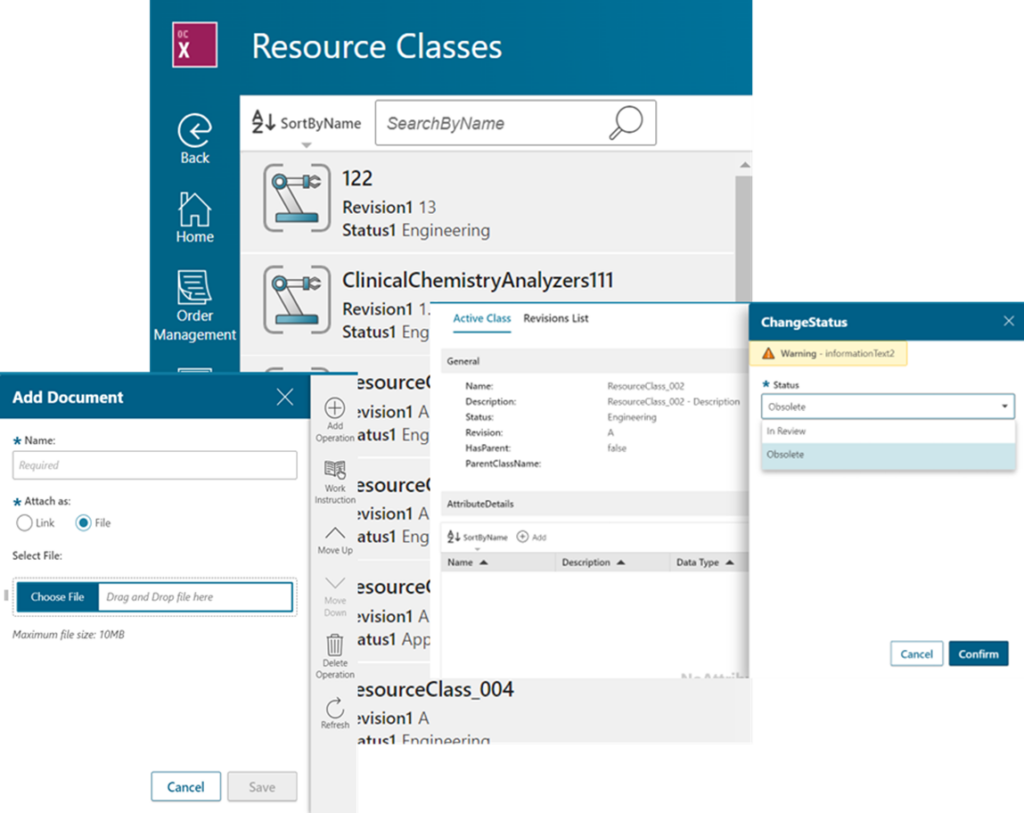

Document management

- Include documents in the process definition

- Download and view documents at runtime opening in a new tab

Resources management

- Resource classes and instances

- Associate resources classes to process operation

- View at runtime which resources are needed to complete a specific operation

- Resource group definition to be used by scheduling module

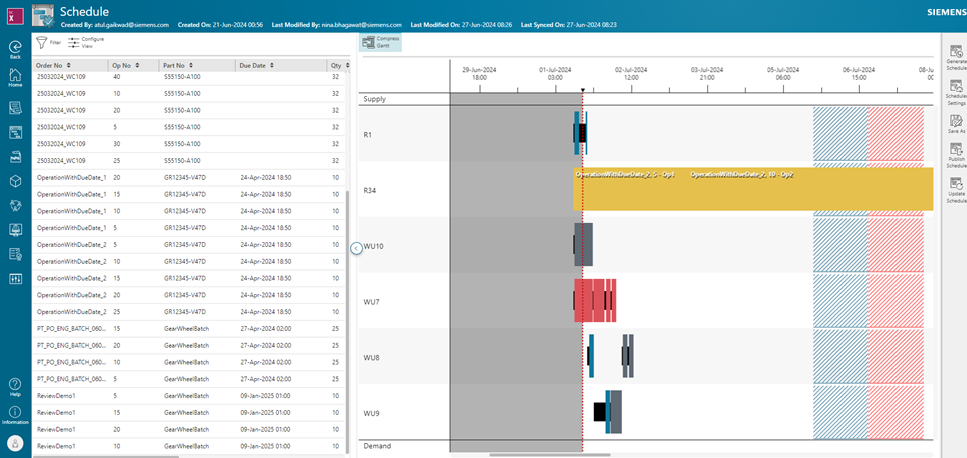

Scheduling (Enhanced gantt interactivity)

- Configurable display range

- Gantt resource filtering

- Relationship highlighting

- Historical period identification

Quality

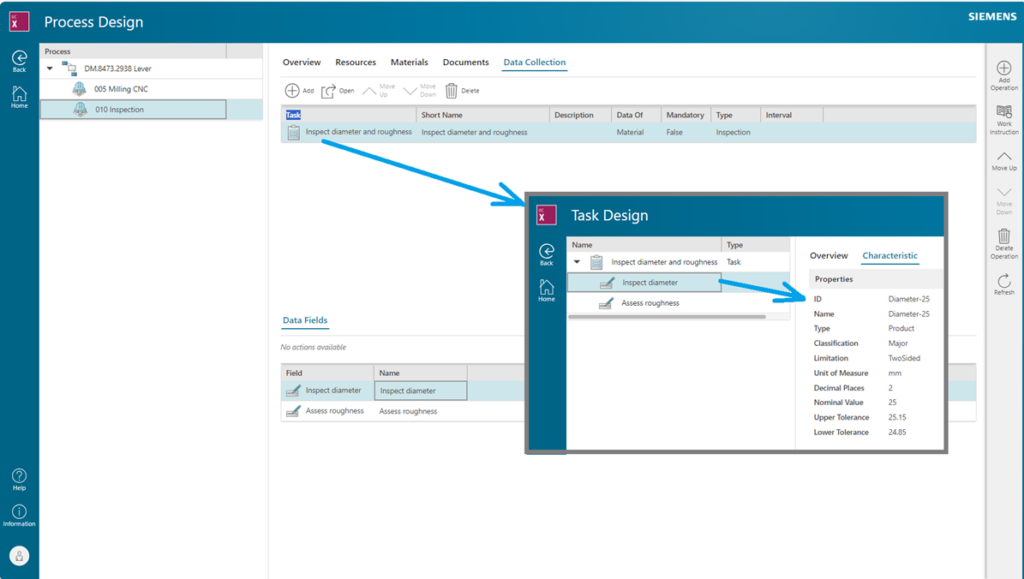

Effortless Quality Control Integration

With our latest feature, users can now easily insert quality tasks directly into our bill-of-process. The operator can conveniently collect relevant quality data directly from the operator terminal, eliminating the need to switch between apps or displays. This fully integrated solution allows for efficient Statistical Process Control (SPC) analysis and streamlines the operator’s workflow, ensuring a seamless and hassle-free experience.

- Non-conformance management

- Consume OK/NOK inspection result of camera gate and create non-conformance

- Edit failure & cause patterns via office page

- Statistical process control

- Support visual characteristics

Process designer

- Specify inspection tasks

- Option to consume a characteristic library

If you are a decision-maker in an SME in discrete industries and resonate with the challenges discussed, consider exploring Siemens’ new solution Opcenter X. It might just be the catalyst your company needs to leap into the future with confidence.

We recommend you also watch – Unlocking the power of Digital Manufacturing with Opcenter X, with the recording of our presentation made at HMI2024.

Try our product through our Trial page, or by requesting a demo.