The role of virtual commissioning in manufacturing quality

Dr. Nezih Yaramanoglu, Program Manager of two major cross organizational research and development programs in Siemens PLM, with the scope on Digital Enterprise and end-to-end machinery production solutions, recently published a blog series featuring the role of virtual commissioning in manufacturing quality.

In Part 1: Manufacturing Quality’s Role in a Future-proof Business, Nezih conveys to manufacturers that if they want to survive in the ultra-competitive market, their manufacturing process must become flexible, high quality and able to adapt and account for different variables. He describes how virtual commissioning is an important part of how manufacturers can make continuous breakthroughs with their machines to accomplish this.

In Part 1: Manufacturing Quality’s Role in a Future-proof Business, Nezih conveys to manufacturers that if they want to survive in the ultra-competitive market, their manufacturing process must become flexible, high quality and able to adapt and account for different variables. He describes how virtual commissioning is an important part of how manufacturers can make continuous breakthroughs with their machines to accomplish this.

Part 1: Manufacturing quality’s role in a future-proof business

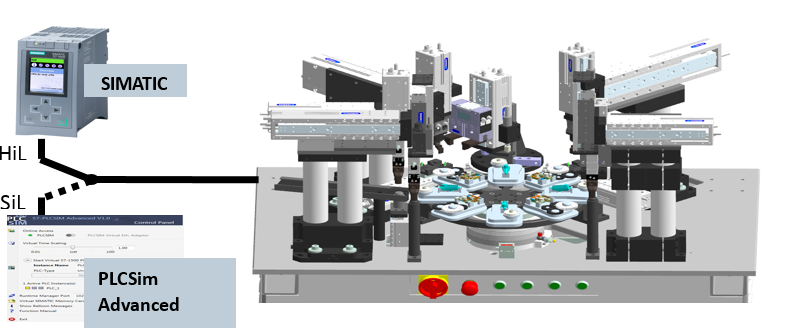

In Part 2: Virtual Commissioning’s Role in Manufacturing Quality, you’ll learn the benefits of virtual commissioning in the design phase. The big difference between traditional commissioning and virtual commissioning is that virtual commissioning can be performed during the design phase before the physical machine is produced. When machine commissioning is incorporated into the processes, manufacturers use a combination of the machine design and information about its future use – a combination that allows the creation of a machine that could ultimately pull businesses ahead of the competition.

In Part 2: Virtual Commissioning’s Role in Manufacturing Quality, you’ll learn the benefits of virtual commissioning in the design phase. The big difference between traditional commissioning and virtual commissioning is that virtual commissioning can be performed during the design phase before the physical machine is produced. When machine commissioning is incorporated into the processes, manufacturers use a combination of the machine design and information about its future use – a combination that allows the creation of a machine that could ultimately pull businesses ahead of the competition.

Part 2: Virtual commissioning’s role in manufacturing quality

In the final blog in the series, Nezih focuses on the virtual commissioning application with the highest impact on production quality and efficiency: virtual commissioning of the production process. Unlike virtual machine commissioning, virtual process commissioning is about using machines on the shop floor where devices such as robots, conveyers and production machines collaborate with each other during production. Virtual process commissioning can be used in two levels of the production systems structure: the sub-system (cell) level, and the system (plant) level. The blog gives you a closer look at the different scopes virtual commissioning plays in these two levels.

In the final blog in the series, Nezih focuses on the virtual commissioning application with the highest impact on production quality and efficiency: virtual commissioning of the production process. Unlike virtual machine commissioning, virtual process commissioning is about using machines on the shop floor where devices such as robots, conveyers and production machines collaborate with each other during production. Virtual process commissioning can be used in two levels of the production systems structure: the sub-system (cell) level, and the system (plant) level. The blog gives you a closer look at the different scopes virtual commissioning plays in these two levels.

Part 3: Virtual commissioning and the production process

About the author

Dr. Nezih Yaramanoglu is the Program Manager of two major cross organizational research and development programs in Siemens Product Lifecycle Management, with the scope on Digital Enterprise and end-to-end machinery production solutions. His focus is on industry processes and their influences on IT solution architectures. Nezih has more than 36 years of experience in IT Solution research and development for production processes. Prior to his current role, he provided development support in initiating and leading strategic Digital Manufacturing projects. He co-founded the e-Factory organization of UGS in 2001 and led the dCADE PBU of UGS Products organization, which merged with Unigraphics Solutions GmbH in 1999. Before the merger, he was the President and CEO of dCADE GmbH, which he co-founded in 1991. Nezih’s academic background is in mechanical engineering. He received a Ph.D. in production engineering from Technical University of Berlin, Germany, where he also received his Master’s degree in biomedical engineering.

Use the comment section below if you have questions or comments about the blog series. Are there other topics you would like our expert team to cover in the NX for Manufacturing blog?