Taking Flight at EMO 2025: Advanced Aerospace Design-to-Manufacturing with AI and Cloud Innovation

EMO 2025 is just around the corner — and this year marks its 50th anniversary. As the world’s leading trade fair for manufacturing and automation technology, EMO brings together innovators, engineers, and manufacturers from across the globe to showcase the future of manufacturing. Siemens will be there from September 22–26, 2025, in Hanover, Germany, and you can find us in Hall 6 / Booth F30.

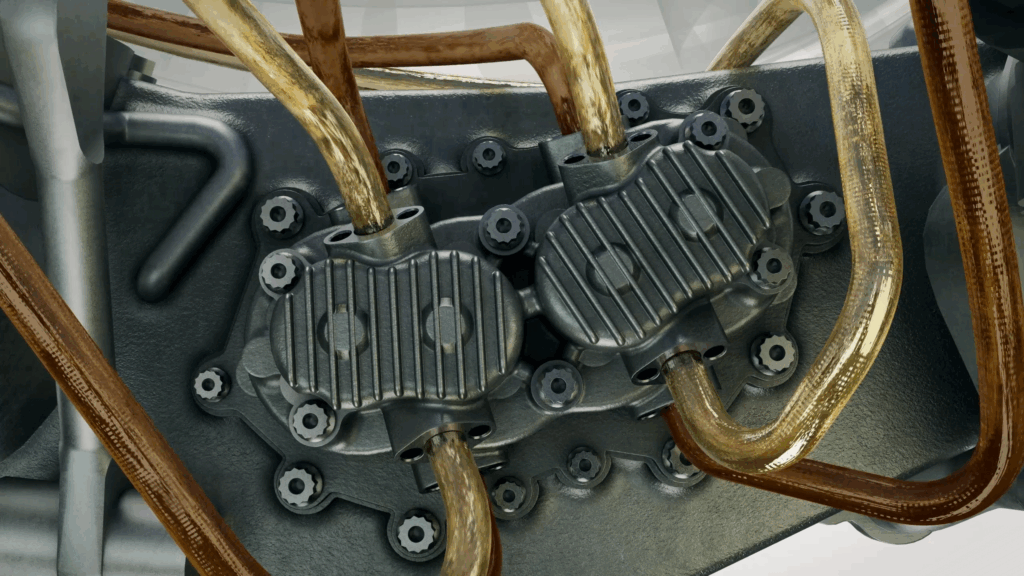

This year, we’re demonstrating the power of a cross-domain digital thread — showing how we can take a jet engine sub-component, the hydraulic lubrication and scavenge pump, and optimize it from design to production using AI, simulation, and cloud-enabled collaboration.

A future concept for Rolls-Royce: optimizing the oil pump

Rolls-Royce, a world leader in aerospace engines, is in the midst of a bold transformation – reshaping itself into a high-performing, competitive, resilient, and growing business. At the heart of this journey are digital technologies and AI, accelerating engineering innovation, boosting operational excellence and unlocking new value. The impact is already clear, from smarter engine design to enhanced operations and customer solutions, but the potential goes much further. To push these boundaries, Rolls-Royce partnered with Siemens to explore how a reimagined production process can help to streamline development and enhance performance for one of its critical components: the lubrication and scavenge pump.

The demonstrator showcases a conceptual digital thread powered by a comprehensive digital twin, enabling seamless collaboration across design, engineering, manufacturing, and quality inspection. By centralizing managed data within an integrated software ecosystem, Rolls-Royce can explore and evaluate countless design and process variations. This unified digital environment drives faster iterations, higher precision, and an optimized manufacturing process for critical components like the lubrication and scavenge pump.

From Digital Twin to Flight-Ready: Reimagining the Scavenge Pump

The lubrication and scavenge pump plays a vital role, generating and maintaining hydraulic pressure to keep the engine operating at peak efficiency. It must function across a wide range of temperatures and endure constant vibrations. At the same time, the pump must meet strict weight targets and align with sustainability goals. Achieving this balance requires a highly coordinated design to manufacturing process for the critical aerospace engine part.

Traditional manufacturing methods — characterized by fragmented workflows, redundant effort, and extended lead times — struggle to meet the precision, performance, and efficiency demands of next-generation aerospace components. To address this, the design and production of the pump must evolve toward an integrated, data-driven approach that seamlessly connects every stage from concept to manufacturing.

From design to production: optimizing the oil pump for flight

Our EMO 2025 demonstrator takes the Rolls-Royce lubrication and scavenge pump through a complete digital thread — powered by AI, simulation, and cloud-connected manufacturing — to make the component lighter, stronger, and more sustainable while ensuring safety and performance.

The process begins in Teamcenter, which manages all data, revisions, and approvals across every stage to keep the right information in the right hands, maintaining traceability and associativity.

In NX CAD, engineers can evaluate the model-based definition provided by Rolls-Royce before moving into a series of simulations. Using Simcenter’s STAR-CCM+ refines the internal geometry for optimal oil flow, while evaluating fatigue, stress, and durability under real operating conditions. These results feed directly into NX topology optimization, which shapes an organic, lightweight structure that maintains strength while reducing material usage. With the design optimized, the team transitions to additive manufacturing preparation, optimizing print orientation, nesting, and support structures, while build process simulations ensure any potential distortions are compensated before printing.

After additive production, the part undergoes subtractive finishing in NX CAM, where the AI-powered NX CAM Co-Pilot accelerates programming by suggesting optimal machining operations, tooling, and parameters — cutting programming time by up to 80%.

The process is validated through G-code simulation and Run MyVirtual Machine, emulating the SINUMERIK ONE controller to verify safe, collision-free machining, while adaptive machining with on-machine probing ensures every feature is in tolerance. The part then moves into automated inspection, where the model-based definition drives CMM programming to verify accuracy and compliance without manual setup.

Slash programming time by up to 80% with the AI-powered NX CAM Co-Pilot.

By maintaining a single source of truth across the process, the result is a pump that is 25% lighter, 200% stiffer, and meets a safety factor of 9 relative to the original concept — ready to deliver performance and sustainability gains in aerospace applications.

See It Live at EMO 2025!

Experience this conceptual digital thread for the Rolls-Royce oil pump — from design to production — in our booth at EMO 2025.

📍 Hall 6 / Booth F30

📅 September 22–26, 2025 | Hanover, Germany

Come see how AI and the Siemens digital thread are shaping the future of manufacturing.