One software solution for the mold manufacturing process

The majority of the plastic parts we use in our daily life are made with injection molds. Injection molds are quite complex assemblies with various moving components. Injection molds are not a new invention; they have been used for decades. The plastic injection molding industry has evolved from producing combs and buttons one hundred years ago to producing products for many industries including automotive, medical, aerospace, consumer products, toys, appliances, packaging, and construction. At the same time, the complexity of the molds, the parts as well as the manufacturing process has dramatically increased over the years.

Why the increase in complexity? A Harbour IQ Quarterly Report states for example that, “Vehicle designs are becoming much more complex and the materials utilized in production are shifting to lighter-weight alternatives. This complexity is driving the demand for more tools and molds, which is positive for the industry.” Simply put, as product complexity increases, so go molds, parts and the entire manufacturing process.

Another explanation for the increase in mold complexity is the availability of 5-axis milling machines making, for example, undercuts on product parts easier to do. Higher demands in mold life and product quality have required the mold components to be manufactured with higher quality making it more challenging to do. Ten years ago, while I worked for a world-leading consumer product manufacturer the norm for, i.e., cell phone cover molds were 4-cavity molds with cycle times of around 8 to 10 seconds. We made, what’s called, a “16-cavity stack-mold”, which is more complex to manufacture, assemble and run, performing with a six second cycle time.

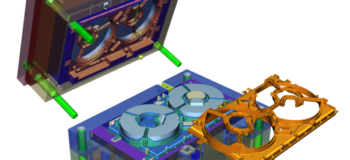

Today, as the complexity is at its highest, it’s essential to enable mold makers to program any job with one software solution. Manufacturing is what differentiates top mold makers. A mold can easily consist of 100+ components in the design that need to be manufactured, i.e. core, cavity, mold plates, sliders, etc. Because there are so many parts, it’s essential to have a powerful tool to manage them. It is also important to understand where they are in the process. Are they made in-house or purchased? Do they require multiple manufacturing steps to be completed, etc.? As the molds have gotten more complex over the years, it imposed higher requirements on the manufacturing process.

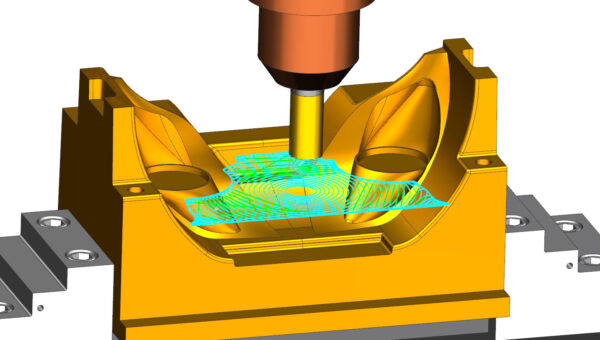

Still today most of the milling is done with 3-axis machining as that is more rigid for roughing. The roughing process needs to be fast and efficient; there no time to waste. Also for finishing, where possible, 3-axis is the preferred choice, for the same reasons.

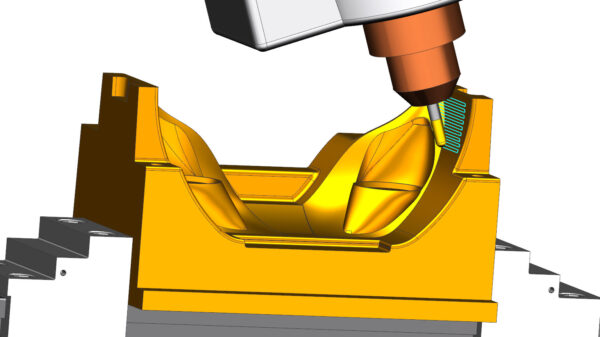

Five-axis machining is being used more and more. For large molds the use of 3+2 machining strategies is implemented, making the use of shorter cutter tools an option. You can tilt the tool axis to reach deeper than with a traditional 3-axis method. Simultaneous 5-axis strategies are used in cases where the part geometry demands it.

The software requirements for both strategies in general is; fast computing of the tool path, a consistent and predictable output, error free and, of course, it has to be user friendly. The tool paths have to run efficiently on the machine tools; which mean no sudden change in direction, no jerky motions and, most importantly, no paths going through the part where it’s unintended.

Many companies try to mill as much as they can on the core and cavities instead of using Die-Sink electrical discharge machining (EDM), as they require additional steps in the process, including designing and machining electrodes. For some product designs it may be necessary to use the Die-Sink EDM process. In that case it’s essential to have efficient electrode manufacturing software that quickly and easily allows you to design and program your electrodes. The electrode manufacturing process is under a lot of pressure as the electrodes have to be ready for the Die-Sink EDM process at the same time as the core and cavities arrive at that process step.

As 3D printing is getting used more in the manufacturing industry, companies have invested in this equipment which enables the printing of raw material for i.e. cores and cavities. Because they print the raw material, they are able to design very efficient cooling channels around the product area which then supports higher efficiency and product control of the mold. Still you need to at least finish milling the surfaces of the cores and cavities, so despite using 3D printing the milling process is not gone. But you could heavily reduce the milling process as the rough milling could be removed if the component design allows for it.

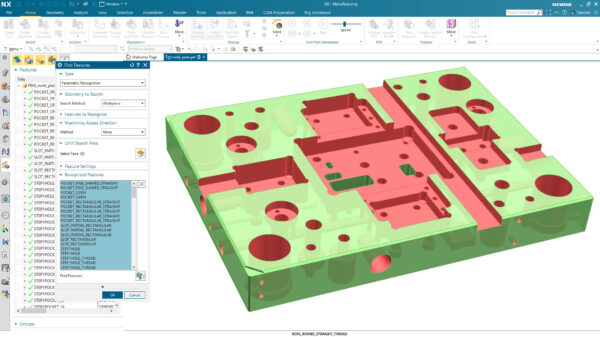

Wire-EDM is also a commonly used manufacturing process, especially for ejector pin holes of various shapes. The software requirements are again — reliability, quality and ease of use. The mold plates are often prismatic parts, with lots of pockets, holes, slots, etc. Additionally, often the feature size is within a certain range, so programming automation can be used effectively. With automation it’s possible to reduce the programming time by more than 90 percent.

For the programmers, usability is critical when deciding which software to use. But if you look at it from a higher level, then training and maintenance are also topics that need to be considered when deciding upon the software. Even though the programming process is different for the individual manufacturing processes, it’s easier to train your staff on a single solution than multiple separate ones. A single software solution is also much easier to maintain.

Siemens NX CAM software is a comprehensive solution that enables mold makers to program all the mold components with one system. It includes a wide range of NC programming capabilities, post processing and machine tool simulation. Many successful manufacturers rely on the automated programming capabilities for 2.5-axis machining, high-speed 3-axis milling strategies to tackle the most complex molds and flexible wire EDM to run any machine tool.