NX CAM 10 provides more power for complex parts machining

New industry-specific capabilities in NX CAM 10 help you program faster and machine better quality parts. In this NX CAM 10 introduction article, we’ll take a look at some of the recent enhancements that are focused on complex parts machining. Several new updates help improve cutting action and surface finish results in 5-axis operations.

Swarf cut turbine blades for the best finish

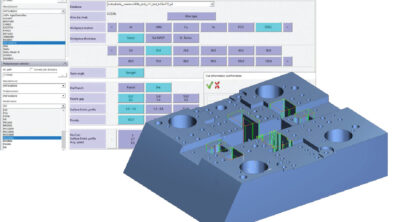

Exact alignment of the tool with the blade geometry can be achieved with the enhanced swarfing in the NX Turbomachinery Milling module. Complex blades can be finished with a single pass using the entire length of the tool, which can produce a high-quality surface finish.

When the component geometry is not perfectly “developable” or able to be perfectly cut with a swarfing operation, the user has the option to ignore minor interferences. This provides a swarf alignment based on a best-fit solution that tolerates small deviations in the surface. So swarfing is possible on a much wider variety of blade configurations.

Figure 1 – Applying a best-fit swarf cut yields excellent surface results for many blade configurations

The gradual engagement of the tool with the material ensures machining with reduced vibrations that further improve the surface quality. Flat, bullnose and tapered end mills can be used to generate a swarfing tool path that machines the entire blade with a single pass.

Improve cutting action for 5-axis machining of rotary parts

The enhanced strategies in NX 10 make it simple to create efficient 5-axis machining operations for large rotary parts, such as aircraft engine casings. Select a single edge and NX will generate all the necessary operations to machine cylindrical faces. The lateral tool offset option enables you to easily create accurate, collision-free 5-axis multiple passes. For some rotary parts, this method can save you hours of geometry creation and model preparation.

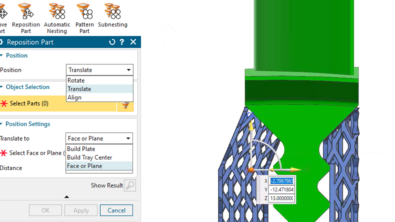

Figure 2 – shifting the tool improves the cutting action for this type of rotary cutting

This shift moves the near-zero surface speed of the tool center to be moved out of the cut in favor of the much more clean-cutting outer diameter of the tool.

Deburring

Also, 5-axis chamfering and deburring operations can be easily generated using this cutting strategy. This style of rotary cutting performs best when the tool engages material on its leading edge. NX provides control over the contact point and offers options for tool shifts in order to optimize the cutting conditions. This results in better material removal rates, tool life and surface finish.

Are you interested in receiving emails whenever we publish new posts to this blog?

(Frequency: Semiweekly) Click here to learn how to subscribe.

About the Author

| Derek has focused on PLM CAM software, in one way or another, since 1992, which sounds like a very long time. He’s written posts, done implementation and training, served as a product manager, and as a marketer. It has all been fun and he’s met a lot of interesting people and seen a lot of interesting machine shops. |