Digitalization in Machine Tool Manufacturing

For visitors working in the metalworking industry, the EMO is undisputedly the leading machine tool trade show in Europe: The EMO 2015 takes place in Milan. In the run-up to this trade show taking place in October, Siemens business managers and technology experts presented the benefits provided by the integrated Siemens portfolio, comprising industrial software and automation components, to customers from the machine tool sector. Approx. 50 international specialist journalists attended the press conference.

TAC Piacenza – Technological know-how and technological innovation

The TAC Piacenza – a competence and training center offering courses on SINUMERIK CNC-controlled machine tools – is, with its application engineers – like all other TACs – an important point of contact for machine tool users. They set innovative impulses for the future developments in this industry sector.

Dr. Wolfgang Heuring spoke about the progressive digitalization, above all in the machine tool industry. During his presentation, Wolfgang Heuring, CEO of the Motion Control Business Unit (DF MC), pointed out, “For machine tool manufacturers and manufacturing companies, we provide a powerful response to the challenges arising in digitalization. We are the only provider who offers an integrated CAD/CAM-CNC process chain as well as solutions for the networking of machine tools and higher-level IT systems. We combine this horizontal and vertical integration with innovative solutions for cutting, the connection of robots as well as additive manufacturing.”

Faster and more flexible development due to Integrated Engineering

Joachim Zoll explained how SINUMERIK helps improve cutting results. Joachim Zoll, Head of the Machine Tool Systems Business Segment (DF MC MTS), underlined in his presentation the importance of an optimized integrated engineering process, “Integrated Engineering describes the increasing interconnection of working processes and applications in the real and virtual world when designing a new machine. The result is a significant reduction of the time, costs and labor as well as a significant improvement of the competitiveness,” stated Joachim Zoll.

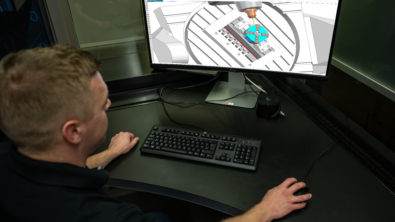

Following the presentations, the Siemens technicians presented the highlights of this year’s EMO live at different stations directly on the machine tools.

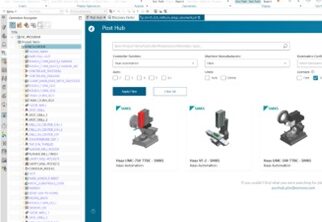

Siemens is already supplying its clients with important elements for the so-called digital enterprise. Siemens’ Digital Enterprise Software Suite comprises software products for discrete industries which meet all the requirements of the industrial value chain. This suite includes a comprehensive portfolio of product lifecycle management (PLM) software like NX and Tecnomatix, and its backbone is Teamcenter software, the world’s most widely used digital lifecycle management solution. NX software is an integrated solution for computer-aided design, manufacturing and engineering analysis (CAD/CAM/CAE), and the Tecnomatix portfolio is a suite of software for designing, planning and simulating the digital factory. And products such as Manufacturing Execution System (MES) Simatic IT, the Sinumerik CNC controllers and the Simatic S7 controller portfolio have also proved their merits in real-life production worldwide.

This year’s EMO takes place on October 5 – 10 at the Fiera Milano trade show center, Italy. The Siemens trade show presentation in hall 3, show booth E06/F03, runs under the slogan “On the way to Industry 4.0 – Digitalization in Machine Tool Manufacturing.” More information about Siemens presence at the tradeshow can be found at EMO 2015 – Digitalization in Machine Tool Manufacturing

To learn more about Siemens NX for Manufacturing solutions, visit our website.