Compressing the moldmaking design and production process

AdvancedManufacturing.org recently published, “Compressing the Moldmaking Design and Production Process,” a look at how moldmakers can greatly speed up design and compress the manufacturing cycle for high-quality molds and die with the latest CAD/CAM and CAE software. We were able to weigh in on the subject and explain that by using the advanced capabilities in Siemens NX software, moldmakers can design and manufacture more accurate products, faster and more efficiently. In today’s blog you can read what our team had to say in the article, then click through to the complete story at AdvancedManufacturing.org.

As tooling for complex products has increased, mold-and-die shops, along with other manufacturers, are turning toward advanced manufacturing processes. “Automation and integration are enablers for our customers to make tooling improvements, with tool design workflow optimization and validation tools to make products more accurate,” noted Himanshu Iyer, NX product marketing manager, Siemens PLM Software (Plano, TX). Paramount for manufacturers, he said, is “making sure that errors, if any, are captured as early as possible in the design cycle. We all know how expensive it is to deal with those later on in the process, and we have to make the process more efficient.”

Poor communication between OEMs and suppliers often causes pain down the line in product development. “One of the issues is involving customers early in the design phase,” noted Daks Azhagappan, product manager for NX Mold Wizard. “You have to look at all of the manufacturability issues. It costs them time and money unless they work very closely. A lot of our customers, most of the tool shops, ask how do I work with OEMs early on?”

Using CAE tools in NX, powered by the Moldex3D engine, users can improve meshes to gain better overall designs. “One thing in the past was to go through tryouts,” Azhagappan said. “A problem they face is warpage. One thing is to come back into the design and change the cooling. Then they may say ‘how can I compensate for the warpage?’” The mesh transformer added to NX 10 enables users to optimize meshes and bring that information into their CAD environment.

The latest tools allow users to do mesh transformations in two stages, in the design stage and in the CAE software, he noted. With the Moldex3D moldflow analysis, “we have a lot of [those] capabilities integrated into NX,” Azhagappan added.

Faster machining techniques in NX CAM also play a huge role in boosting moldmaking productivity and achieving faster machining times with high-speed technology, noted Sashko Kurciski, Siemens product marketing manager, manufacturing solutions and NX CAM. “We’re reducing machining times by 60% in some cases,” he said. “It can [also] extend tool life by four times.” With the latest NX 12 CAM, Siemens has added an internally developed high-speed roughing strategy that uses component technology. “It’s a new technology for us that’s similar to Volumill but in some cases is better,” Kurciski said. “It’s not an add-on.”

Additive technology is another important factor. “It will have several impacts on the tool industry, in our opinion. One of those areas is conformal cooling,” Iyer said. “With additive techniques, we see customers already thinking about things differently.”

With hybrid subtractive/additive machines in the market, the advantage is being able to automate processes on either side of the machine and between those sides, Kurciski said. A shop can build a mold with the additive side with internal cooling channels, and then “you can use the same machine to achieve the high quality surfaces they need for molds.”

Read the complete article here.

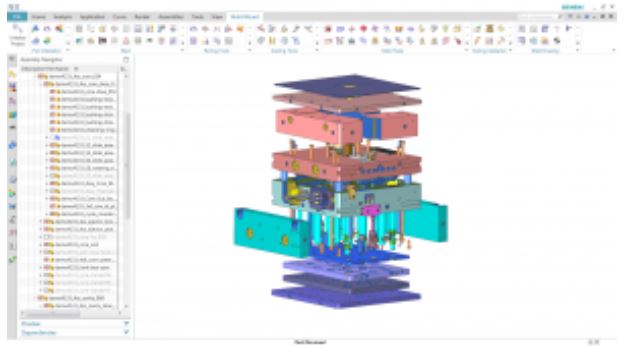

The many levels of a mold are shown in this NX mold assembly simulation from Siemens PLM Software. The latest NX offers new tools for moldmakers, including conformal cooling techniques and mesh capabilities.

The many levels of a mold are shown in this NX mold assembly simulation from Siemens PLM Software. The latest NX offers new tools for moldmakers, including conformal cooling techniques and mesh capabilities.