What you missed at CES 2026

For four days last week, the tech world converged on Las Vegas for the CES 2026 technology conference. There, Siemens CEO, Roland Busch, took to the main stage to talk about how Industrial AI, the digital thread, and Siemens have combined to positively impact some of the largest companies and most promising projects occurring today. As Roland explained, this combination of AI and the digital thread means that companies now can utilize the data inherent in their processes to optimize their operations taking gains that were once only theoretical into the real world.

As an organization, Siemens has committed itself to being at the forefront of this data-driven revolution. With a deep history of utilizing technology to benefit the future, Siemens sees this convergence of new Industrial AI technology with our longstanding commitment to the digital thread as a huge enabler for the future of manufacturing.

Manufacturing takes over the main stage at CES 2026

This convergence was in evident display as Roland unveiled our new Digital Twin Composer that allows companies to visualize and simulate any product, plant, or factory. What this means for manufacturers is that you now have the ability to conduct large-scale simulation and virtual commissioning of entire factories in their full context, in real time. You can train autonomous robots in unmanned factories, simulate the various different components of a factory, and visualize the entire workings of a factory before a single plot of ground is broken.

During his keynote talk on the main stage at CES, Roland also invited two partners on stage to discuss how Industrial AI and the digital thread are impacting manufacturing. PepsiCo and Microsoft both discussed how Industrial AI and the digital thread are creating new opportunities for manufacturing with regards to optimization, efficiency, customization, and sustainability.

PepsiCo’s initiative to drive optimization through technology

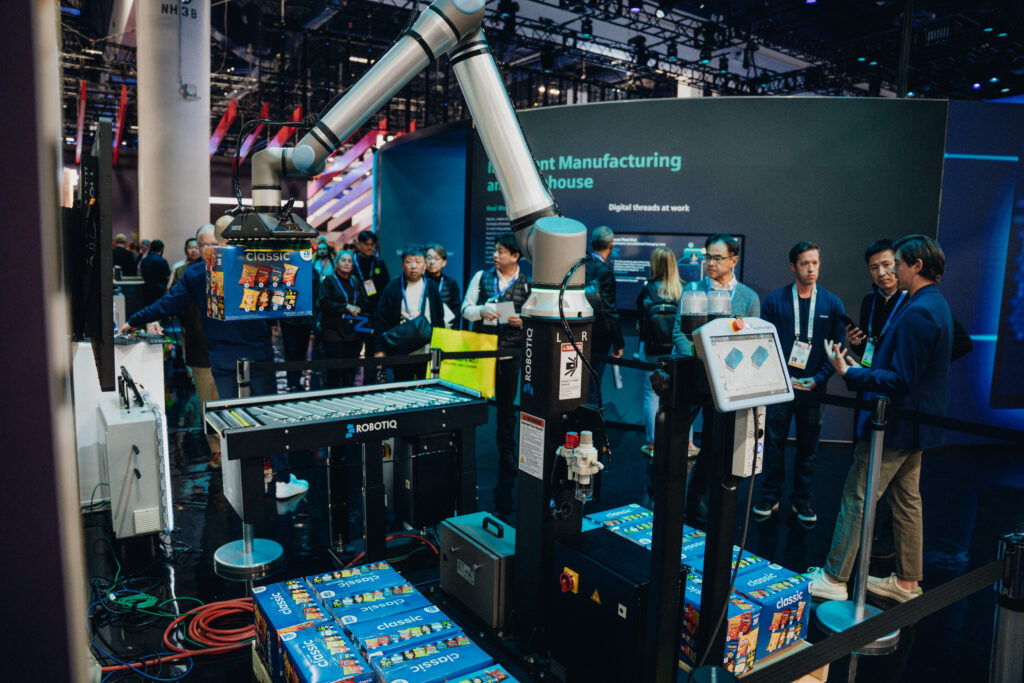

PepsiCo’s CEO for Latin America and their Global Chief Strategy and Transformation Office, Athina Kanioura, joined Roland on stage to describe their use of the new Digital Twin Composer, and she extended the discussion with a customer spotlight interview after her talk on the main stage.

As part of a new initiative, PepsiCo partnered with Siemens and Nvidia to begin creating highly accurate digital twins of their manufacturing and warehousing facilities. Within the project, PepsiCo models every machine, robot, conveyance system, and all of the associated real estate. They then use the new Digital Twin Composer with these virtual models and environments to realize new optimization opportunities.

As Athina said during her interview, “The technology gives you a massive opportunity, because if you are able to simulate [important] parameters in a way that allows you to look at the blind spots, to assess potential disruptions that might happen on the way while you design [your facility], then when you do perform the actual implementation, you are 90% there. Whereas typically what has happened in the past, people just go do the trial and test in the production line. Which, then of course, costs money, effort, and sometimes it compromises other big key KPIs that we don’t want to compromise.”

Microsoft and Siemens facilitating Rolls Royce’s manufacturing initiatives

Likewise, Roland talked with Jay Parikh, the Core AI Team Lead at Microsoft as they discussed Industrial AI and how Siemens partners with Microsoft to make the potential of Industrial AI a reality for customers like Rolls Royce.

Jay described how he believes we are now in the “3rd wave” of AI where multiple agents utilizing different models can now work in parallel to solve complex problems. Companies are now working to train AI models with their own corporate data to perform tasks that are much more complex than the simple queries and one-dimensional tasks possible with the first and second waves of AI.

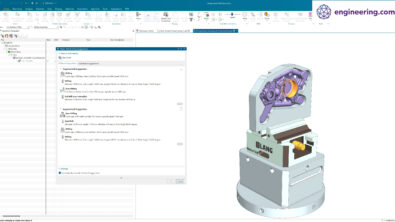

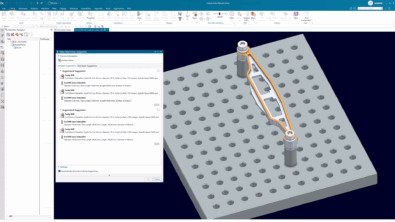

“AI Copilots helped to reduce the CAM programing time by 80%” – Jay Parikh

Roland and Jay discussed how Rolls Royce uses Siemens and Microsoft technology to create a digital twin of their aircraft engines so they can simulate machining programming. With the use of complex AI Copilots like the AI Make Machining Suggestion function in NX X Manufacturing, Jay described how Rolls Royce has been able to reduce their CAM programming time by as much as 80%, resulting in 30% better productivity in their manufacturing operations.

Through examples like these, Roland and our partners used their time on the main stage at CES 2026 to discuss the present and future of manufacturing. However, the main stage at CES was only part of the Siemens presence as manufacturing also took pride of place in the Siemens booth at CES.

Manufacturing front and center at the Siemens CES 2026 booth

In the Siemens booth at CES, the new Digital Twin Composer was, of course, a large focus. However, there were also other interesting projects to explore for manufacturers. Attendees visiting the Siemens booth at CES had the opportunity to dive deeper into the PepsiCo story as well as to learn about Haddy, a company manufacturing large-format furniture using additive manufacturing.

Haddy is a pioneering U.S. startup that’s transforming manufacturing through large-scale, AI-powered 3D printing. Haddy’s business revolves around their use of sustainable, localized micro factories that produce high-quality parts from recyclable and biodegradable materials. With their micro factories and additive manufacturing, Haddy directly addresses critical challenges like global supply chain disruptions, urgent sustainability demands, and the need for rapid production agility.

For CES, Siemens showcased Haddy’s work with Disney to produce large-scale 3D models for their theme parks. Featured at the Siemens booth for CES 2026 was the King Louie throne that Disney developed for their entertainment partners. Haddy can print the base of this furniture, efficiently and quickly. The base is then finished, painted, and dressed, resulting in a fully functional piece of furniture, straight from the imaginations at Disney, but manufactured in a micro factory by Haddy.

Haddy relies upon the Siemens digital infrastructure stack for their production, and tools like the new AI Make Machining Suggestion functionality automate programming of complex parts utilizing AI to enable the deployment of Haddy’s scalable micro factories, reducing transportation emissions and fostering local economies without compromising operational efficiency and sustainable innovation. As Haddy expands its network across the U.S. and Europe, their partnership with Siemens is driving the future of agile, environmentally conscious manufacturing, making it a must-see story for any manufacturers who visited the Siemens booth at CES 2026.

CES is becoming a “must see” event for manufacturers

Each year, the number of real-world technologies unveiled at CES relevant to manufacturing increases. Meanwhile, the convergence of digital twins, Industrial AI, and automation is resulting in accelerating innovation in the manufacturing industry, and Siemens continues to invest heavily in this future. Our presence at CES is also increasingly becoming a venue where Siemens showcases the newest and most important innovations in the manufacturing space with an ongoing commitment to showcasing real-world examples of how these technologies are making an impact today. So, if you missed us at CES 2026, you may want to put CES 2027 on your calendar today.