CAM is in our DNA [article]

The famous quote by Charles Darwin, “It is not the strongest of the species that survives, nor the most intelligent that survives. It is the one that is the most adaptable to change.” is a perfect reflection of the significance of embracing change in all industries, including manufacturing.

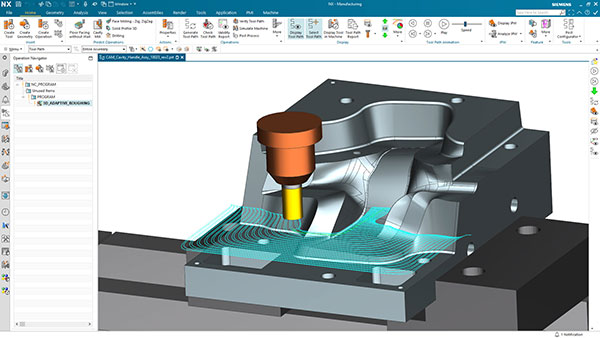

In today’s manufacturing world, technology is rapidly advancing, and computer-aided manufacturing (CAM) is no exception. The latest automated techniques, like feature-based machining, have revolutionized the NC programming process. You can recognize standard features such as pockets, slots, and compound holes (sometimes hundreds of them) and generate the necessary toolpaths to machine them in a matter of seconds. This has made CAM programming faster and easier, enabling re-use of best practices.

Even though automation can increase efficiency and accuracy, there are certain aspects where manufacturers’ expertise and decision-making skills are critical.

CAM is in our DNA. The CAM tools in NX are targeted at the professional users —programmers and manufacturing engineers

Vynce Paradise, head of Siemens NX CAM

Siemens NX CAM software is a prime example that illustrates how NC programmers and machine operators can work alongside to create the most efficient machining process. The software enables seamless integration of their expertise in machining.

Evolution of NX CAM

Today, NX software is a solution that provides a comprehensive suite of CAD/CAM/CAE applications but what many people may not know is that the software’s origin was CAM.

Our remarkable journey started with a CAM program called UNIAPT in the seventies that was instrumental for aerospace giants like McDonnell Douglas to streamline their machining process and create complex parts and components with great precision and accuracy. Since then, design and simulation features were added, evolving into Unigraphics, then the present-day NX in the Siemens Xcelerator portfolio.

“CAM is in our DNA,” says Vynce Paradise, head of Siemens NX CAM. “The CAM tools in NX are targeted at the professional users—programmers and manufacturing engineers.”

Contrary to popular belief, NX CAM is not exclusively designed for advanced users, it caters to a wide range of users. “In every machine shop, you see a mix of simple and advanced programming.” he adds.

“We’re continuously trying to find out if there are things to improve in the software, like reducing excessive tool wear, and then fixing them before we release the software,” says Vynce whose team of application engineers collaborate with industry partners to improve the software.

Machinists and automation: a dynamic duo

In CAM programming, the synergy between human machinists and automation is very essential to define the optimal machining process. Machinists bring to the table, their wealthy knowledge and experience of operating complex machines, and automation on the other hand brings speed, precision, and consistency to the manufacturing process.

“If you’re always making the same part, then you can automate the process, but when it comes to parts with high variability, you still need someone who understands the process. If you’re going to make a complex part, like a turbine blisk, you’ll still need weeks to program it,” Vynce says. That is why the human machinist’s role remains indispensable and must work in tandem with automation to achieve better results. The machinists’ expertise is so invaluable that they are skilled at even making in-situ decisions such as adjusting the spindle speed based on just an observation

“An experienced machinist can tell just by listening to the machine’s sound,” says Vynce.

Learn more on how to combine the machinist’s wisdom and automation in CAM by reading the full article on Digital Engineering 24/7, the industry’s primary resource for the latest technologies, industry news, and trends.