Teaching AI to speak the language of Engineering and Manufacturing through Industrial Foundation Model

Gen AI (Generative Artificial Intelligence) can read text and images, but it struggles with complex industrial data. What if AI could be trained to understand the very language of engineering and manufacturing? At Siemens, we are making this a reality by developing an Industrial Foundation Model that brings true industrial intelligence to manufacturing.

In 2022, OpenAI shook the world by introducing ChatGPT. Since then, generative AI (GenAI) has begun supporting tasks in engineering and manufacturing such as generating technical documentation, boilerplate programming, summarizing data, and answering common technical questions.

But here’s the big question:

If you work in engineering or manufacturing, is today’s GenAI enough for you?

The short answer: No.

The industrial world is far more complex and runs on 3D CAD data, bills of materials, process simulations, toolpaths for CNC programming, tolerances, and quality inspection datasets. If AI can’t interpret these, it can’t truly collaborate with engineers and manufacturers.

That’s why we’re building something different — an AI that understands your domain from the ground up.

An Industrial Foundation Model: The Next Leap in Industrial-Grade AI

We are entering a new era where AI is not just a generalist. It becomes a specialist that understands the precision of engineering data, the complexity of manufacturing workflows, and the standards that keep operations running smoothly.

“We are entering the next step of industrial-grade AI as we are empowering industries with AI that understands and enhances engineering processes, driving productivity, innovation, and growth”

Tali Segall, Head of Industrial Foundation Model, Siemens

To make AI truly industrial grade, it must be trained to speak the language of engineering fluently.

What Is the Industrial Foundation Model?

An Industrial Foundation Model is a large-scale generative AI, like well-known models like GPT, but specifically fine-tuned for the industrial world. This means it truly understands the language of engineering and can work with the complex types of data engineers handle every day.

Trained on vast amounts of industrial data, it can deliver precise and relevant answers tailored to daily engineering and manufacturing needs. Built to meet industry standards, this model offers the trustworthiness, accuracy, reliability, and security that are essential for real-world industrial applications.

Powering digital manufacturing applications with AI

AI is transforming how products are designed, planned, and produced. By combining data, automation, and intelligent insights, AI helps manufacturers work faster, make better decisions, and deliver higher-quality results.

At Hannover Messe 2025, Tali Segall, who is leading the Industrial Foundation Model initiative at Siemens, had some insights to share. Watch the video to discover the digital manufacturing applications that the Industrial Foundation Model can address.

AI-assisted CAM programming

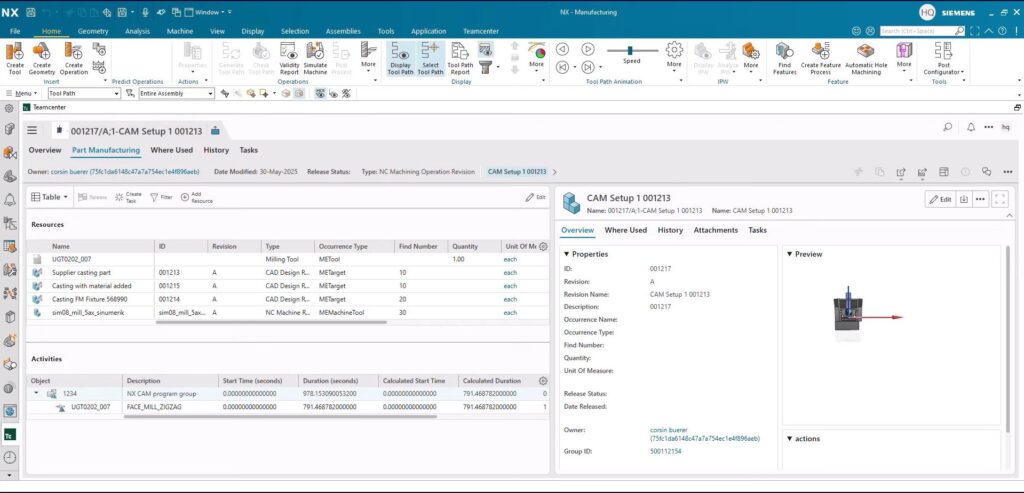

Ask any NC programmer and they will tell you that too much time is lost in repetitive, manual toolpath creation. CAM programmers today need to spend too much time generating and adjusting toolpaths needed to manufacture components. Gaining the necessary expertise require years of expertise, making it costly and reliant on a limited skilled workforce. The Industrial Foundation Model can streamline the process by understanding engineering data, industry best practices, and specific knowledge from past projects.

This AI-powered model can suggest cutting strategies, tools, and toolpaths while enabling direct interaction through an intuitive user interface. It can identify machining features, recommend strategies, and justify decisions, automating key aspects of CAM programming to save valuable time and reduce skill dependencies.

This was demonstrated in NX X Manufacturing, where an AI co-pilot instantly reads the geometry, identifies features, and delivers the right cutting strategy, tooling, and operations on the spot. No library searches. No repeated data entry. Just fast, intelligent, and context-aware programming.

AI-powered Manufacturing Planning

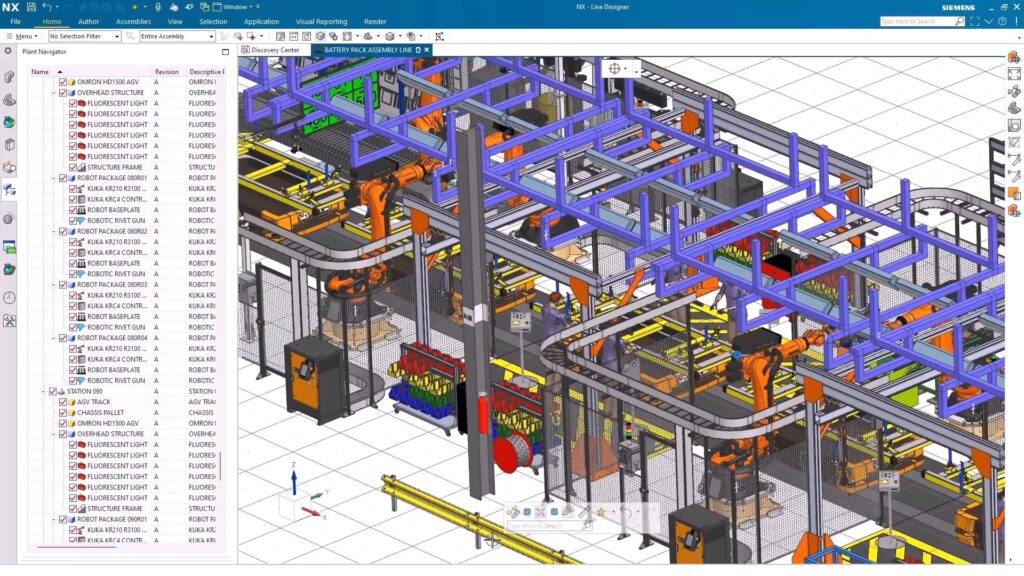

Planning engineers spend a lot of time turning design data into detailed manufacturing plans. Tasks like converting an EBOM into an MBOM or a bill of process can take hours or even days. The Industrial Foundation Model is designed to change that by connecting directly to robotic simulators and factory layout tools.

Using this AI technology, planning steps that used to take forever, such as generating production line layouts that follow company-specific rules or running virtual process validations, happen quickly and automatically. This means less time spent on repetitive work and more time for engineers to focus on solving problems, improving workflows, and driving innovation.

AI-enabled simulation for simulation and validation

Simulation and validation processes have always required a careful balance between accuracy, time, and resources. Engineers often spend hours creating datasets, preparing separate models, and running lengthy validations before a single part is produced. The Industrial Foundation Model is set to change this.

By working directly with connected process planning datasets, AI can validate assembly processes in 3D on the fly without needing to duplicate data. It can check feasibility, highlight potential issues, and suggest process improvements well before production begins.

Factory layout planning also benefits because AI can automatically factor in all company-specific regulations and requirements, ensuring compliance without manual effort.

Delivering the core benefits of GenAI

Generative AI brings many benefits, but through conversations with customers, three key advantages of the Industrial Foundation Model stand out:

Bridging the Skills Gap

By gathering and organizing company and industry knowledge in one place, Industrial Foundation Model makes it easier for new engineers to learn. New hires can quickly understand processes, standards, and best practices without spending months shadowing or searching for information. This helps close the skills gap and eases pressure caused by the shortage of experts.

Enforcing Standards

Trained on company-specific data and industry best practices, the model helps engineers follow the right standards and avoid costly mistakes. This ensures work stays consistent with company guidelines, reducing errors and rework.

Boosting Productivity

By taking on repetitive, manual, and non-innovative tasks, Industrial Foundation Model frees experienced engineers to focus on what really matters — solving complex problems, exploring new ideas, and applying their creativity. This means less time spent on routine work and more time driving meaningful improvements, allowing skills to be used where they have the greatest impact.

The Road Ahead

The Industrial Foundation Model is designed not only to understand engineering data but also to think through engineering challenges. It learns the data, rules, and precision that drive industrial processes.

This model will transform how companies design, plan, manufacture, and operate across the entire value chain.

Human–machine collaboration in industry is no longer just a concept — it is happening right now.

We are leading AI innovation across digital manufacturing. Curious to learn how?