Unveiling innovation at IMTS 2024: Siemens digital thread featuring additive manufacturing in next-gen products

Join Siemens at IMTS 2024, the largest manufacturing technology show, where we showcase a transformative approach to manufacturing high-performance EV components using an end-to-end digital thread. We’ve focused on redesigning the eRod’s transmission housing to withstand high forces, particularly in sport mode, and to reduce noise and vibration during deceleration. Using the Siemens Xcelerator software portfolio and our extensive partner ecosystem, we’re pushing the boundaries of digital manufacturing. Let’s explore how we optimized the design stage for additive manufacturing.

Get a sneak peak & watch the video featuring additive manufacturing in next-generation products!

Optimizing design for additive manufacturing

Strengthening the eRod’s transmission housing

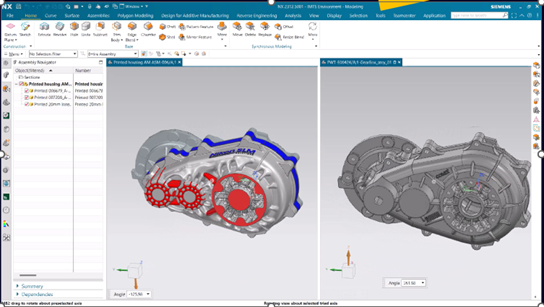

To enhance the eRod’s transmission housing for high-performance driving, we utilized advanced design tools from the Siemens Xcelerator portfolio to increase structural integrity while reducing weight. Topology optimization helped us create a material layout that withstands high forces without compromising performance. This process not only strengthened the component but also reduced noise and vibration during deceleration.

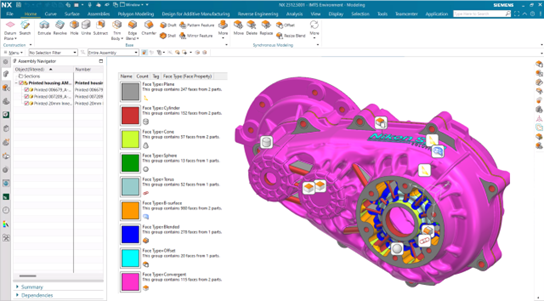

Integrating data in a single CAD model

Optimizing the transmission housing design required integrating both pre-existing and new data into a single parametric CAD model. This allowed us to work on faceted and B-Rep data simultaneously, ensuring all changes were updated across the entire model. The result was a more streamlined design process with fewer errors and faster production readiness.

Overcoming design barriers for additive manufacturing

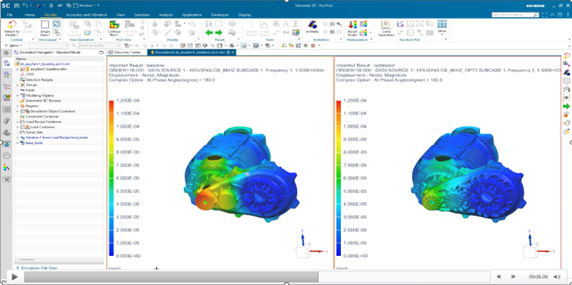

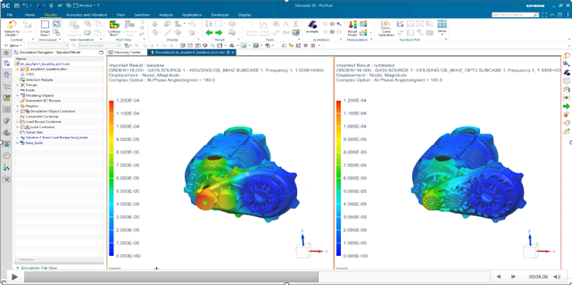

Designing for additive manufacturing required overcoming traditional barriers to create a production-ready part from the first iteration. The importance here was to efficiently develop an optimized design for additive manufacturing while also preparing the build tray in the same associative environment verifying designs and prints using Simcenter 3D simulation integration to achieve first-time-right printing.

Siemens and its partners are redefining digital manufacturing by leveraging an all-digital approach. Our additive manufacturing solutions create components that outperform and outlast conventional versions, demonstrating the power of integrating cutting-edge design tools and innovative manufacturing techniques. Visit us at IMTS 2024 to see how Siemens is leading the future of digital manufacturing with an end-to-end digital thread, setting new standards in the automotive industry.