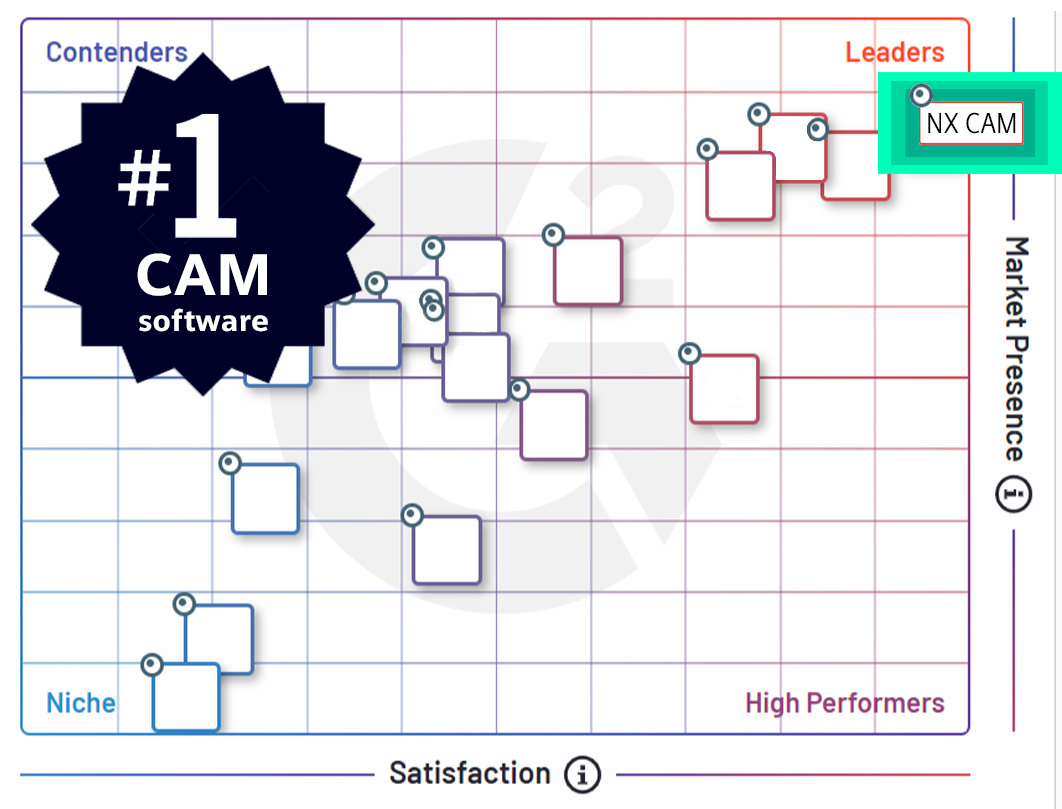

NX CAM ranked as #1 CAM software on G2

G2 Fall report 2024 is here and NX CAM ranks as #1 CAM software.

Manufacturing experts, like you, have recognized NX CAM as the leader in the CAM (computer-aided manufacturing) software category.

With insights from over 100 CNC programmers, NX CAM stands out among other CAM software options, as shown in the live G2 Grid Report below:

This demonstrates our commitment to developing the most complete and advanced CAM software, which is both scalable and seamlessly integrated into the Siemens Xcelerator, our comprehensive software portfolio for digital transformation.

Our users, who provide constant feedback, make this possible. Based on their input, we incorporate significant and powerful new capabilities into each new release to address the most challenging machining requirements and enhance the overall CAM experience. During Spring 2024, NX CAM earned 7 more badges from our users from around the world and across all major industries, including automotive, aerospace and industrial machinery industry sectors.

What are the benefits that #1 CAM software provides?

While selecting the right CAM software for your machining jobs might be challenging, G2 makes the decision-making easier. It provides featured comparison criteria to help CNC programmers understand and differentiate the distinctive features of each CAM software provider.

CAD to CAM

The transition from CAD to CAM is essential because it ensures a seamless flow of design data into the manufacturing process, facilitating an efficient production process.

NX CAM has the capability to read any standard CAD format. Customers find the most advantage when they utilize the integrated CAD/CAM functionality in NX. It ensures a smooth transition from the CAD part model to the CAM environment to create necessary machining operations to manufacture the part.

By maintaining the associativity between CAD and CAM data the design changes are automatically reflected in the machining process, enabling seamless workflow and minimizing rework.

CNC Programming

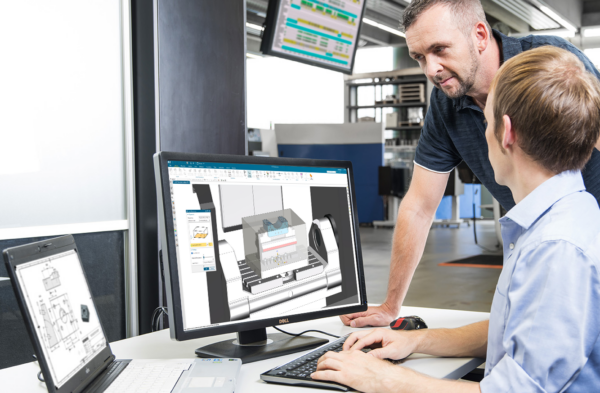

To effectively program the increasingly challenging components, manufacturing companies need to equip programmers with powerful CAM software.

That’s why it’s crucial for the software to be user-friendly yet capable. This allows programmers to define the machining process for parts of any complexity faster, while having full control of all the machining parameters. With NX CAM, you get streamlined CNC workflows even for the most complex 5-axis machining.

For prismatic parts, NX CAM simplifies CNC programming with its automated Feature-Based Machining capabilities. You can program complete parts with many (sometimes hundreds of) features (e.g. pockets, compound holes, and slots) in minutes, saving hours of valuable programming time. By automating repetitive tasks and recognizing machining features, NX CAM helps programmers reduce machining time by up to 90%.

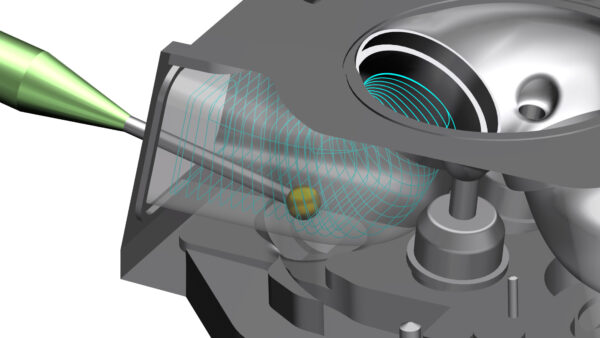

CNC Machining

Advanced toolpath strategies enable part manufacturers to achieve greater efficiency and improved parts quality. NX CAM provides a range of toolpaths that helps streamline the machining process and reduce the overall machining time. Operations like 3D Adaptive Roughing speed up the toolpath generation significantly faster which boosts the part programming speed for the user and helps to remove the bulk of the material 60% faster than the traditional methods. With the smooth-flowing finishing strategies in NX CAM, users achieve mirror-like surface finish, while extending tool life and improving the overall productivity.

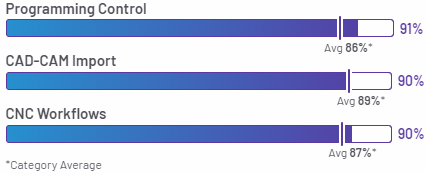

Data behind the ranking

Customers assessed CAM software through G2’s scoring framework. Below is the detailed information on how NX CAM was rated by the users for some of the key capabilities:

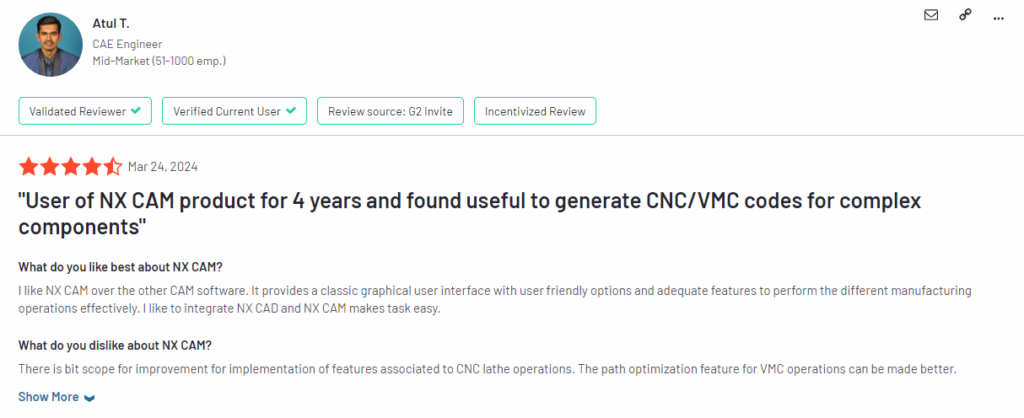

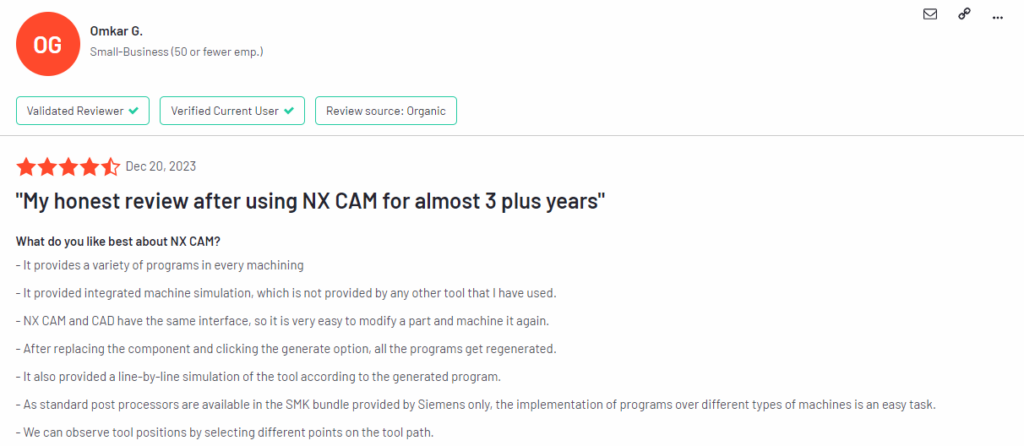

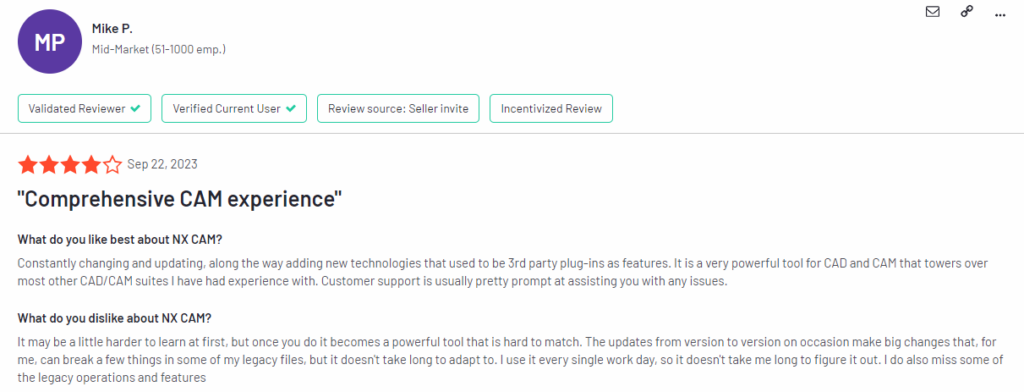

Listen to what our users are saying

Learn more about NX CAM software and get direct insights from NX CAM users about their favorite aspects of the product:

Curious to see why the CAM experts leave 5-star reviews of NX CAM?

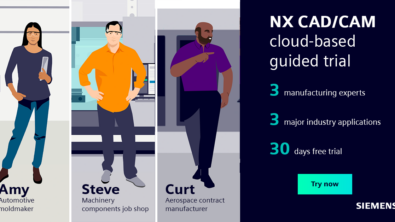

Check out the NX CAD/CAM cloud-based free trial. It includes guided experiences for different industries, including:

- Automotive mold manufacturing

- Machinery component machining

- Aerospace part manufacturing

Click here to access your free NX CAD/CAM cloud-based guided trial.

Join our active and dynamic NX CAM community to stay updated on the latest enhancements and product updates related to the NX CAM software.

Explore Siemens NX X Manufacturing on the cloud

NX X Manufacturing brings a new level of flexibility, scalability, and efficiency to part manufacturing through cloud-based technology. With three product tiers—Standard, Premium, and Advanced—you can select the solution that fits your specific needs.

Take customization further with value-based licensing and over 20 add-ons, giving you the tools to adapt your software to any project.

Read the blog to learn more about NX X Manufacturing

Using NX CAM? Leave your feedback

If you use NX CAM, the part manufacturing community would love to hear from you.