What’s New in NX 11 for Design Engineering

NX 11 for Design Productivity

Convergent Modeling

Convergent modeling can be used in the medical industry, in this case for a cranial implant.

Convergent modeling can be used in the medical industry, in this case for a cranial implant.

Many industries use scanned 3D data as part of their design processes. If you have worked with this data in the past, you know how painful it can be to make it usable. Irregular shapes in particular require extensive reverse engineering so that they can be used for 3D printing, mold design, analysis or other uses. Convergent modeling in NX 11 reduces the need for this rework by bringing the scanned data in as facets, so there is no need to map surfaces, create solids, or do any other manual shape creation. You can scan your data and immediately begin building supports for 3D printing, creating molds based on the shape, including it in an assembly, analyzing it, or performing any other operation that you would with CAD data. Convergent modeling represents a huge savings in time and cost and eliminates the error-prone rework phase. Whether you are designing medical devices, retail or apparel products, or utilizing clay models for styling and design, convergent modeling is a critical tool for creating facet shapes more quickly and with fewer errors than other solutions.

3D Printing

NX 11 has the strongest 3D printing support yet. In addition to convergent modeling, you can 3D print your designs directly from NX by using File>3D Print. Since this functionality uses the 3D printing toolkit offered with Microsoft® Windows® and the widely supported the 3D Manufacturing Format (3MF), you can rely on wide compatibility.

Feature Modeling

Sweep a body along a 3D path to create geometry the same way it is machined.

Sweep a body along a 3D path to create geometry the same way it is machined.

Parametric solid modeling is the foundation of modern 3D design. NX 11 builds on this foundation with tools like swept volume, which enables you to create design features the same way they are created with machining processes – by sweeping a solid body along a 2D or 3D path. A simple new tool for creating an associative bounding volume is particularly useful for tooling and fixture design. New options for interrupting and renewing feature builds give you more control over the model and make it easier to take advantage of legacy data. Hole creation functionality is improved with emphasis on threads and depth settings. Selecting what you need in the context of your work is easier than ever, too.

Surfacing

Flatten and re-form curved surfaces in NX 11Surface modeling remains a vital tool in most industries, particularly for industrial design and styling. NX 11 reinforces a strong surfacing tool set with new and refined functionality. With curve scaling, you can create scaled copies of curves, part edges or points as a new feature with the option to make it associative to the original. You can now flatten a curved surface, make changes to it and re-form it to its original shape, giving you more control to use the workflow you want. Sheet trimming is faster and easier because sheets need not extend past the cutting object. With variable offset faces in NX 11, you can create a body with constant and variable thickness in one operation, which is particularly useful for lightweighting. Finally, variational sweeping is improved to make it easier to create complex shapes in fewer steps.

Flatten and re-form curved surfaces in NX 11Surface modeling remains a vital tool in most industries, particularly for industrial design and styling. NX 11 reinforces a strong surfacing tool set with new and refined functionality. With curve scaling, you can create scaled copies of curves, part edges or points as a new feature with the option to make it associative to the original. You can now flatten a curved surface, make changes to it and re-form it to its original shape, giving you more control to use the workflow you want. Sheet trimming is faster and easier because sheets need not extend past the cutting object. With variable offset faces in NX 11, you can create a body with constant and variable thickness in one operation, which is particularly useful for lightweighting. Finally, variational sweeping is improved to make it easier to create complex shapes in fewer steps.

Flatten, modify, and re-form curved surfaces in NX 11.

Sheet Metal Design

Sheet metal design in NX is also improved. You no longer need a separate aerospace sheet metal license to access these commands and functionality. In NX 11, the commands have been rewritten, improved and incorporated into NX Advanced Sheet Metal. Advanced flange creation is now part of the base sheet metal architecture, improving reliability and compatibility with other sheet metal commands. You can create more complex joggles with new support for intermediate web faces and adjacent web faces. Enhancements to other functions such as lightening cutouts, solid punches, bridge bends, beads and dimples, normal cutouts, and contour flanges help you create the geometry you need in fewer steps with more versatility and control. From NX 11, bridge bends are available to all users within the standard sheet metal license.

Create the geometry you need in fewer steps with sheet metal design functions of NX 11.

Synchronous Technology

Giving you the ability to work on any model, regardless of origin, as well as the ability to add intelligence to dumb data, synchronous technology in NX leads the industry. Incremental improvements in NX 11 include the ability to replace a face with another that includes open edges. You can now delete faces to split a single body into multiple bodies. Finally, automatic face selection makes it easier to optimize faces.

Sketching

Designers spend a great deal of time creating and modifying the sketches that drive geometry. In NX 11, the sketcher has a number of enhancements that give you more control and make it easier to make changes and find the information you need. For example, you can now decide whether to display automatic dimensions, so you can make your screen less cluttered while still retaining the benefits of auto-dimensioning. When you move geometry in a sketch, you get an improved visual preview of the curves you are moving, and the associated dimensions move with the curves. It is also easier to scale sketch geometry. You have the option to scale around the sketch origin or on the first driving dimension. With the new scalable sketch group functionality, you can designate a group of features to be scaled, which is especially useful for re-usable objects that may not come in at the correct size.

NX 11 also gives you more control over how sketch geometry is constrained; points and vertices on curves can now be horizontally or vertically aligned with other points and vertices, and the midpoints of lines and arcs now have selectable vertices that can be used for constraints. The new sketch relations browser is a powerful tool for investigating and debugging sketch objects. It allows you to easily find associated constraints, dimensions and external references, a significant aid in diagnosing sketch issues. Enhancements to spline creation make it easier to achieve G1 and G2 continuity. Creating sketches is easier than ever with a simplified dialog box. Finally, performance is enhanced by giving you control over various display options.

NX 11 also gives you more control over how sketch geometry is constrained; points and vertices on curves can now be horizontally or vertically aligned with other points and vertices, and the midpoints of lines and arcs now have selectable vertices that can be used for constraints. The new sketch relations browser is a powerful tool for investigating and debugging sketch objects. It allows you to easily find associated constraints, dimensions and external references, a significant aid in diagnosing sketch issues. Enhancements to spline creation make it easier to achieve G1 and G2 continuity. Creating sketches is easier than ever with a simplified dialog box. Finally, performance is enhanced by giving you control over various display options.

Scale entire sketches or portions of sketches in one step.

NX Realize Shape

Since its introduction in NX 9, NX Realize Shape™ has been continuously improved and refined. An intuitive subdivision design tool that uses simple shape manipulation to create high-quality B-surfaces, NX Realize Shape is easy to use and more capable than ever. In NX 11, you can split and merge bodies and use the clipboard to copy Realize Shape features such as cages or geometry. This makes it easier to re-use and share information from models. The new connect capability gives you the ability to attach subdivision bodies to geometry created outside the Realize Shape environment. It even fills in any gaps between the bodies, so you can make use of subdivision shapes in any model. You also have more control over the elements of the subdivision model with the ability to delete part of a cage or move or copy single elements in a body. When creating a primitive shape, you can now specify the density and number of horizontal and vertical segments in the cage to get the exact shape you want. Exclusive selection simplifies the user experience by automatically deselecting the previous object when a new one is selected.

NX Layout

NX Layout is a 2D concept design tool that supports fast, intuitive concept design with full NX integration and easy adaptation to 3D. In NX 11, it is even more powerful. New functionality accelerates the creation of 2D layouts by automating the creation of 2D components from 3D parts and assemblies. By selecting a section or projection of a 3D object, you can easily create the 2D component. You can even select an assembly and preserve its structure in 2D. You also have more control over the display and hierarchy of the layout with new commands for reordering, drag-and-drop, and the ability to apply a user- or system-created order to your components. With better control, you can explore concepts in 2D more efficiently and quickly.

Working in a complex layout with many parts can be a challenge, but NX 11 has tools to make it easier. Editing in isolation enables you to work on an individual component by itself, without the distraction of all the other components in the layout. When you need to view the full layout, the active component is highlighted in a different color while the background components retain their original colors. With the new automatic preview functionality, you can see a live preview of the component as you create or modify it to reduce the risk of errors and improve productivity. Copying components is faster and easier; you can simply press the CTRL key and drag a component to make a copy. NX Layout also delivers improved functionality with non-native 2D data, eanbling you to import “blocks” of data as re-usable NX 2D components.

Create 2D components from 3D parts.

PMI and Annotation

More and more companies are now taking advantage of Product and Manufacturing Information (PMI) to support their model-based definition (MBD) strategies. Leveraging PMI for downstream use in design and manufacturing, better quality control and faster access to critical product information provides significant benefits over traditional drawing-based processes. Many companies also tend to have large amounts of legacy 2D drawings, and to leverage this legacy data they must deal with the effort of recreating information from a drawing in the 3D model. This process can be time-consuming and must be manually verified to insure that relevant 3D information matches the information from the drawing. Using NX 11, you automatically convert drawing views and objects to model views and PMI objects. These objects include dimensions, geometric dimensioning and tolerancing (GD&T), notes and more. It is highly customizable, with options for drawings, sheets, views and annotation objects. Converting to PMI can be performed interactively or via an automated batch process. NX has always had a strong commitment to making legacy data useful without rework. With PMI conversion, you can use legacy NX drawings to add intelligence to 3D models quickly and easily.

Automatically convert drawing views and objects to model views and PMI objects.

With user interface (UI) and functional enhancements in NX 11, it is now faster and easier to generate dimensions. You can designate a secondary depth dimension for a hole callout to specify a hole or thread depth. You can also associate PMI dimensions to routed systems objects for improved interoperability. Improvements to sectioning and creating supplemental geometry provide greater flexibility for many common workflows. For companies that continue to produce drawings, a new derived section line type makes it easy to create section lines that are associative to PMI cutting plane symbols found on the model. These enhancements and others are designed to improve productivity in annotating models and leveraging them in downstream processes.

Drawings remain an important part of the design process for many companies, and NX Drafting remains a state-of-the-art tool for creating and maintaining them. In NX 11, smart lightweight views can take advantage of multithreaded processing to save time when working with large assembly views. The new drawing comparison toolset dramatically reduces drawing checking time by quickly and easily identifying changes, and helps eliminate manufacturing errors that may result from drawing changes. Using NX 11, you can also display multiple assembly arrangements on a drawing to provide more information about how the product is assembled, and to show internal details or alternative builds. The arrangement views can also be edited inside NX Drafting. NX 11 adds more settings to support a number of drafting standards and simplify the creation of standards-compliant drawings.

Reduce checking time with drawing comparison tools.

Teamcenter Integration and Active Workspace

NX and Teamcenter are better integrated in NX 11. It is easier for suppliers and OEMs to work together; OEMs can export attribute templates, enabling suppliers to use their customers’ attributes for better communication and fewer errors. Intelligent save automates decisions about how to save multiple modified parts in one session in a single dialog. Internal property names are now displayed to provide clarity when there is more than one property with one name.

Active Workspace in NX gives you easy access to critical product information.

Active Workspace in NX gives you easy access to critical product information.

NX users have had easy access to a broad range of PLM capabilities for several releases thanks to Active Workspace. This embedded client makes it easier to implement a complete PLM strategy by lowering barriers to entry. With mobile access, no separate license and no need for installation, Active Workspace enables any CAD user to see their critical product information anywhere. In NX 11, Active Workspace is faster than ever. New capabilities such as the ability to drag and drop parts to NX enable you to easily open or add parts to an assembly directly from Active Workspace. There is no need to open a separate application to access workflows such as release and change processes; in NX 11 you can do access them directly from within NX. You can select multiple objects in Active Workspace and they will be selected in NX, and vice versa. It is easier to investigate interpart relationships by opening the NX Relations Browser directly in Active Workspace. With easy access to the most important information about your product, you can make better decisions faster.

High-performance rendering

Knowing what your product will look like before you make it is a great advantage in any industry. Photorealistic rendering helps you make decisions about aesthetics, function and materials early on, when those decisions are less costly. NX 11 extends visualization capabilities with the new Lightworks Iray+ rendering engine. Fully integrated into NX Ray Traced Studio, the Lightworks Iray®+ engine boasts a large library of materials and scenes, and is multi-threaded to take advantage of modern microprocessors and GPUs. If you need results even faster, you can utilize other computers to assist with the heavy work of rendering. It’s also progressive, meaning that it will continue to improve the quality of the image indefinitely, giving you more control over rendering completion. With the Lightworks Iray+ rendering engine, NX Ray Traced Studio is easier to use than ever, helping you to make product decisions faster.

Photorealistic rendering shows you what your product will look like before you make it.

Point Cloud Processing

Point cloud data is used in many industries to capture the as-is status of products, factories, plants, buildings and infrastructure objects. NX 11 introduces point-cloud processing using Bentley® Pointools™. Now you can import cloud point data in the standard POD file format, make simple measurements and perform editing functions such as show/hide, transforming, deleting, and editing of parameters. This makes it easier to access reference data, particularly for applications including plant and line design, without needing to create 3D data.

Point cloud data makes line design easier and more accurate.

Usability

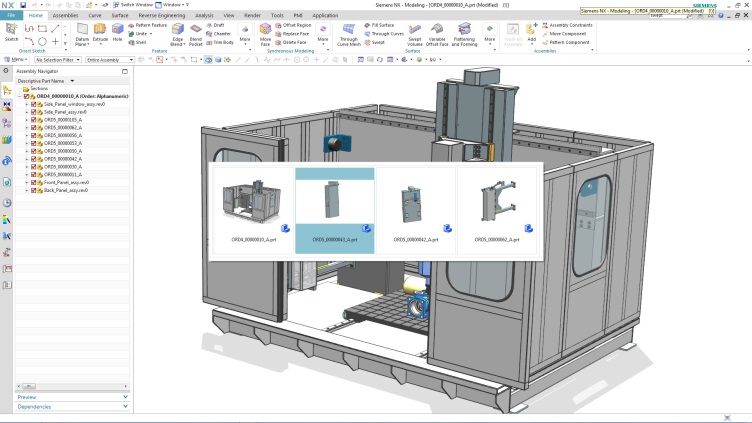

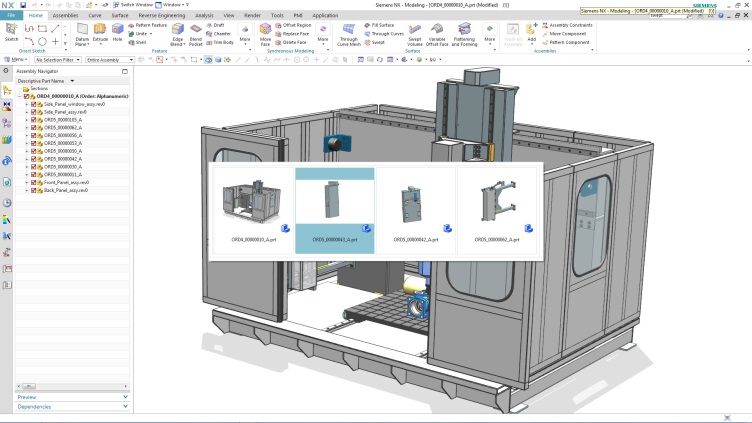

NX gets faster, more efficient and easier to use with every release. In NX 11, switching between windows is fast and intuitive with CTRL-Tab and a window with thumbnails of all active parts. In addition, parts now open in the NX application they were last saved in. The detailed part information you need is now much easier to read and navigate with HTML information windows. Improved touch functionality and 4K monitor support all contribute to making NX easier to use so you can get the job done faster.

Ctrl-Tab window switching saves time and clicks.

NX on the Cloud

For some configurations of NX 11, you have the option of deploying and running NX in a cloud-managed environment. This enables you to take advantage of new NX features while also gaining many of the benefits offered by cloud-based offerings, such as reduced complexity, time, cost and risk involved in installation, maintenance and upgrades. It also means that NX will still perform and respond as you are accustomed to. Additionally, your IT team can focus on core business functions instead of managing the environment. NX on the cloud gives you flexibility, scalability and reliability that helps you match business demands as they change.