Realize LIVE blog series: Natilus | Visualize at scale with immersive engineering

In the rapidly evolving world of aviation, disruption and innovation are key to differentiating yourself from the competition. One company leading this change is Natilus, spearheaded by its CEO and co-founder, Aleksey Matyushev. At Realize LIVE 2024, Aleksey shared insights into the company’s vision, groundbreaking technology, and partnerships, shedding light on how Natilus is shaping the future of air cargo. Here’s a closer look at their journey and the exciting developments ahead.

A new era in air cargo

Natilus was founded in 2016 with a mission to innovate where there has been little innovation for a long time — cargo aviation. As Aleksey points out, “We saw something shift in the marketplace and specifically three key changes really driving a need for something new.”

These changes include:

- E-commerce revolution: The advent of companies like Amazon has significantly shifted consumer expectations towards almost instantaneous delivery of goods, emphasizing the critical role of air freight in the supply chain.

- Sustainability: Environmental goals set by airlines to reduce or eliminate CO2 emissions by 2030 or 2050 are pushing for new, sustainable aircraft designs.

- Pilot shortages: A significant shortage of pilots, amplified by the growth in the passenger sector, is impacting the cargo industry first.

The blended wing body design

To address these challenges, Natilus has moved away from traditional tubular aircraft configurations to a more innovative blended wing body design. This design, which was initially studied by McDonnell Douglas, Boeing, and NASA in the late 1990s, offers substantial benefits for cargo transport.

Aleksey explains, “The blended wing body offers one and a half times more revenue cargo for the same trip. It is about volume, not weight, that drives air freight today.” Furthermore, this design coupled with scalable autopilot systems and sustainable aviation technology can reduce operational costs by up to 80%.

Pioneering unmanned aircrafts

A significant milestone for Natilus is the certification of large, unmanned aircraft by the FAA. “For the first time ever in 2013, the FAA has allowed for a large, unmanned aircraft certification into the national airspace system,” Aleksey notes. Natilus is among the few companies capitalizing on this, pushing forward the concept of autonomous air cargo transport.

Meeting market demand with innovative products

To showcase the efforts towards unmanned aircrafts, Natilus has developed a range of diversified aircrafts. Here are some of the key products:

- Kona: A four-metric ton payload aircraft for regional cargo, designed to connect smaller regional airports to larger hubs.

- Alisio: Designed to replace Boeing 767 and Airbus A330, it offers transatlantic capabilities, ideal for intercontinental routes.

- Nordes: The most profitable among Natilus’ offerings, this 100-ton aircraft is poised to replace the Boeing 777, designed for heavy cargo transport.

What sets these products apart is their design. Unlike traditional aircraft with upper and lower decks, Natilus aircrafts feature a single deck layout with high ceilings and a 45-degree inclined cargo bay, maximizing volume and efficiently accommodating various cargo types from e-commerce packages to oversized machinery.

Embracing sustainability

Natilus is at the forefront of integrating sustainable aviation technologies. While their aircrafts are compatible with traditional jet fuel, they are also engineered to operate with Sustainable Aviation Fuels (SAF) and potentially hydrogen in the future. Their partnership with ZeroAvia highlights this commitment. Aleksey elaborates, “We believe that in the next 10 to 15 years, there’s an opportunity for hydrogen.” The blend of wing body design is particularly well-suited for this transition as it can house hydrogen without compromising cargo space.

Innovations with Siemens and immersive engineering

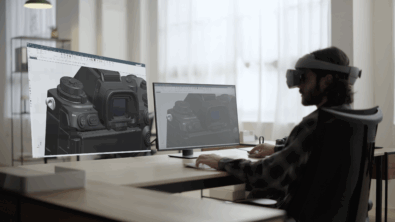

Collaboration between Natilus and Siemens has been instrumental in implementing advanced engineering tools. Aleksey shares, “The thing I like about NX the most is the amount of tools that it gives you.” The immersive engineering demo has allowed Natilus engineers to visualize the physical scale of their designs in real-time, facilitating better design and assembly processes.

The future of aviation with augmented reality

Looking ahead, Natilus envisions heavily leveraging augmented reality (AR) for more efficient design and manufacturing processes. This technology promises to revolutionize how engineers collaborate, visualize parts, and even interact with customers. As Aleksey emphasizes, “Imagine coming into a customer’s hangar and essentially putting on that headset…size and scale all come together.”

Conclusion

Natilus is not just building aircrafts — they are restructuring the very fabric of air cargo transportation. Their innovative designs, focus on sustainability, and use of cutting-edge technology position them as a real player in the aviation industry. With an impressive order book and substantial market potential, Natilus is set to transform how goods are transported around the globe. Check out the links below to learn more about what Natilus presented at Realize LIVE 2024.

Comments

Leave a Reply

You must be logged in to post a comment.

Natilus, led by CEO Aleksey Matyushev, is revolutionizing cargo aviation with innovative designs and technology. At Realize LIVE 2024, Aleksey highlighted their mission to address e-commerce demands, sustainability goals, and pilot shortages. Natilus’ blended wing body design and unmanned aircrafts promise substantial benefits. Web Gate here is also for design.