Optimize the collaborative PCB manufacturing process

This white paper looks at 10 areas where electronic and mechanical designers working with printed circuit boards (PCBs) face the dysfunctional nature of their collaborative tools. Leverage the powerful capabilities in NX and Siemens Xpedition for solutions to the following:

- External and internal copper and solder mask/silkscreen data

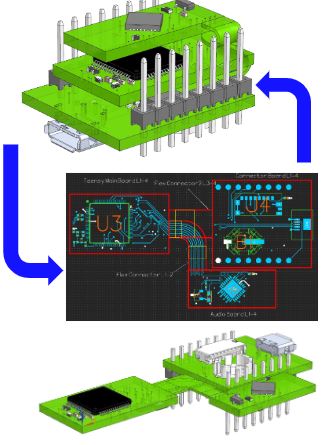

- True 3D model exchange and synchronization (pin 1 verification)

- Full 3D Interference checking

- Rigid-flex objects (multiple thickness boards, stiffeners, etc.)

- High density interconnects and miniaturization

- Variant exchange

- Design intent collaboration (ownership, frozen groups)

- Workflow synchronization

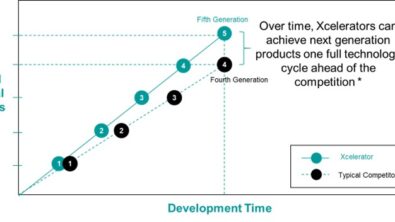

PCB design solutions provide cost savings and productivity gains

Electronics designers and manufacturers face a considerable challenge to find systems that provide a significant advantage. With the mechanical design power of NX and the innovative PCB design solutions in Xpedition, product designers and engineers have the tools to revolutionize their workflow. The cohesive solutions found within NX and Xpedition provide efficiency, cost savings and productivity gains that extend across organizations. Download the white paper to learn more.