What’s new in NX | Simulation Driven Design

Welcome back to the latest instalment of our what is new in NX™ software series. Our previous entry into the series explored new capabilities within Model Based Definition (MBD); If you typically deploy Model Based Definition in your workflow (or are looking to in the future), head on over to our blog to see new features!

The following instalment will look at Simulation Driven Design, comprised of new enhancements to our Topology Optimizer and Design Space Explorer. A combination of these two products enables you to create a comprehensive digital twin of your 3D model, whilst validating multiple design options with ease. Let’s dive in!

Topology Optimizer

WHAT IS THE TOPOLOGY OPTIMIZER?

A generative design solution for designers to lead the product design process from concept to production, converting design requirements and specifications to a manufacturable design

New functionality with the solver

An improved and faster convergent scheme

We’ve listened to the community and added key functionality to the solver. Firstly, we’ve implemented a trust region scheme within the solver to allow move limit adjustments to the optimizer, whilst enabling you to use the restart strategy when the solver fails.

What does this mean for you? Well, the vibration analysis convergence has significantly improved; your test cases now converge in less than 200 iterations, whilst the Max Stress and Max Displacement constraint will also converge faster.

Material Penalization update

An additional solver improvement revolves around the material penalization functionality within NX. We’ve worked on and updated the material penalization scheme for a more gradual 0-1 distribution. What we’ve done is focused on discontinuities in the design space/ disjoint bodies, focused on test cases with many sub cases, and multiple loads with big differences in order of magnitude.

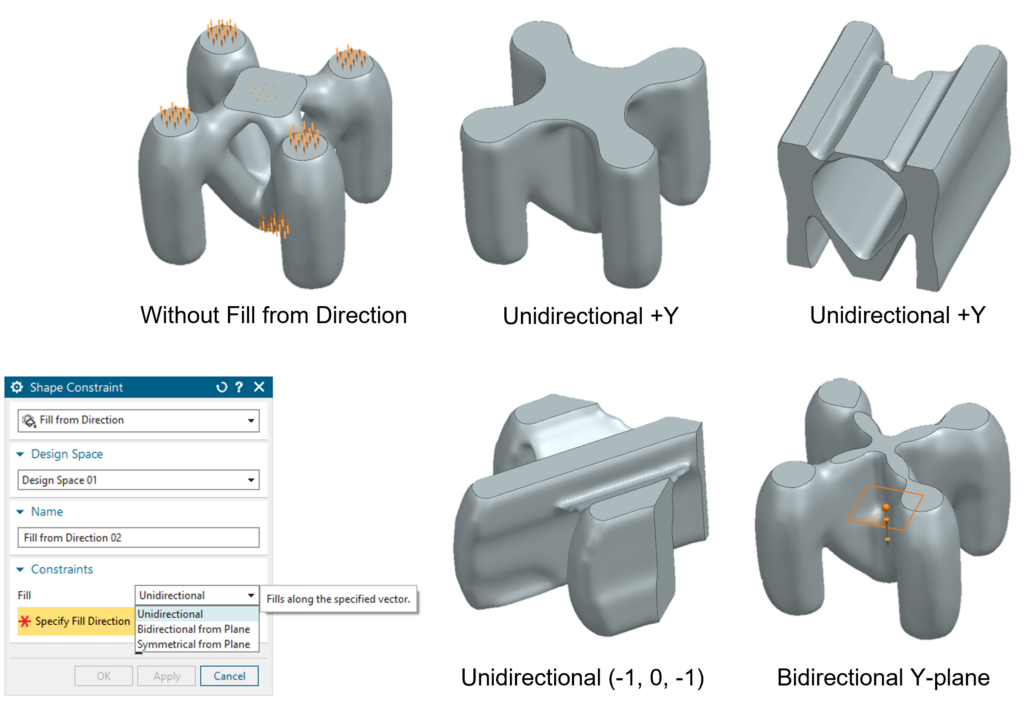

A new manufacturing constraint – Fill from Direction

Further feedback from our users indicated that new shape constraint functionality was a must. So, we’ve added a Fill from Direction feature. This new functionality can be used to impose fabrications requirements such as castability, where it is important that a part does not “lock the mold”. Additionally, material can only be added in a region by “filling up” in each direction from a base plane. Implementing Fill from Direction into your geometry lays the groundwork for greater design optimization to meet functional requirements earlier in the design phase.

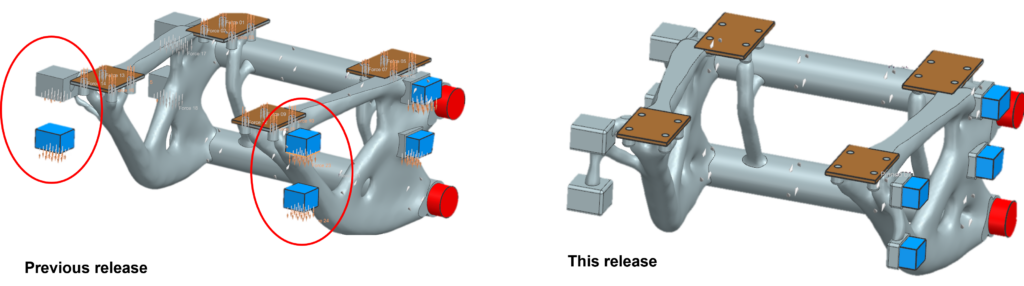

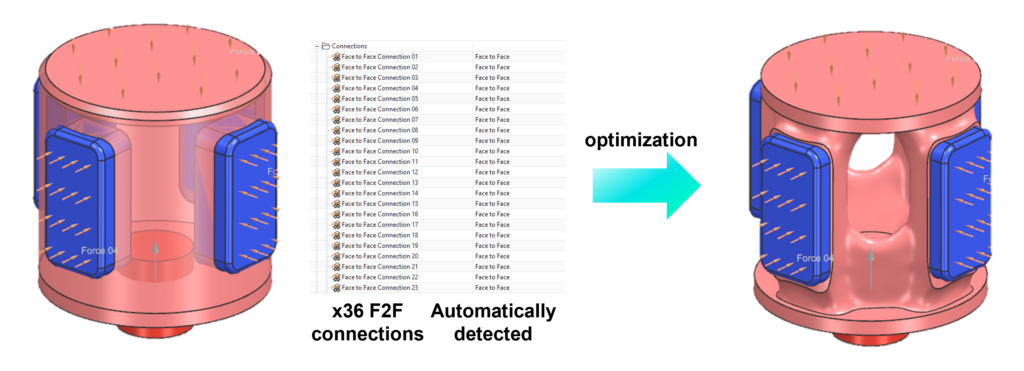

Auto detection of connections

Let’s look at another feature added to our Topology Optimizer. We have created and developed the ability to auto-detect connections; this means existing connections between scenery bodies and design spaces are automatically detected. You can use this feature for face-to-face and body-to-body connections, whilst also having the ability to cycle through pairs options to review and create a connection. It’s a great tool to solve complex design constraints automatically to reduce development (or setup) time.

Design Space Explorer

WHAT IS DESIGN SPACE EXPLORER?

“An application that modifies the specified design variables, complying with design constraints to achieve the specified design objectives.” Design Space Explorer is an optional add-on module you can implement into your workflow that automatically explorers broader design spaces to more rapidly discover better designs.

Let’s take a look at the latest enhancements we’ve added to Design Space Explorer for this latest release!

SHERPA methods

First and foremost, let’s take a look at SHERPA as a concept:

“SHERPA employs multiple search strategies at once and adapts to the problem as it learns about the design space. SHERPA requires significantly fewer model evaluations, enabling greater design optimization and reducing design time by days, or even weeks!

With that in mind, what are the two exploration methods we have added into this release?

Weighted Sum of all Objectives

The method takes all objectives into consideration and provides solutions based on the weighted sum of all the objectives in question. If all objectives get better or worse when combined, this method is the best approach to finding the optimal solution. SHERPA is efficiently learning about the design space and adapts so as to effectively search a range of design spaces, no matter the complexity

However, if the objectives conflict (weight and load-carrying ability), the trade off can be explored using the next study option, ‘Multiple Objective Tradeoff Study.’

Multiple Objective Tradeoff Study

This option is perfect when working on a project with multiple objectives that clash with one another. It broadly works the same as the weighted sum of all objectives but has the advantage of handling multiple objectives independently of one another. Objective trade off studies, or ‘pareto optimization’ selects the optimal designs based on whether they dominate other designs.

WHAT IS A DOMINANT DESIGN?

“A design is said to be dominate another when it is better in at least one objective and not worse in all other objectives.“

Feasible designs that are not currently dominated by any other designs are given the first rank. The remaining designs are re-ranked and those that are not dominated by any other design in that group are given the second rank. The procedure is repeated and so on. You’ll then be left with a ranked list of design options, giving you the opportunity to determine the best fit solution to your needs, or whether further exploration is needed.

SHERPA methods are a vital tool to use within any workflow. The aim of the enhancements to this tool are to ultimately make life easier for you when using NX, no matter your level of experience. Non-experts can successfully apply automated optimization the first time they use it, whilst enabling all users to find better solutions the first time without the need to iterate or identify the best method to use.

Units support through expressions, Constraint violations plots

We’ve added new functionality to the Design Space Explorer, where you can refine and more accurately determine your constraint responses. Constraint responses contain the limiting performance factors for the search. They enable the user to codify the product requirements so designs that do not meet them can eventually be eliminated. As an example, you might be working to a structure which will be subjected to a certain amount of force, resulting in that structure needing to support x pounds. NX enables you to set multiple constraint limits to eliminate designs that are not suitable, thus allowing you to save time by quickly identifying the most suitable designs to implement. Anything that sits outside of an ‘Acceptable Range’ will be deemed as an error and eliminated from the design.

REMEMBER:

The default values for the Acceptable Range fields are a very negative minimum number (-1.0d300) and a very large maximum number (1.0d300). This is usually fine, but some studies may require a little customization to eliminate designs that should be errors.

Conclusion

And that concludes our latest entry into the what is new in NX for the December 2022 release! As a recap, we’ve taken you through the latest enhancements for Simulation Driven Design, with close attention on the Topology Optimizer and Design Space Explorer. These new features are with the user in mind, and we hope you are able to implement these capabilities into your workflow.

If you liked this entry, why not continue your journey with NX…