How Additive Manufacturing Combines Design, Manufacturing, and Simulation

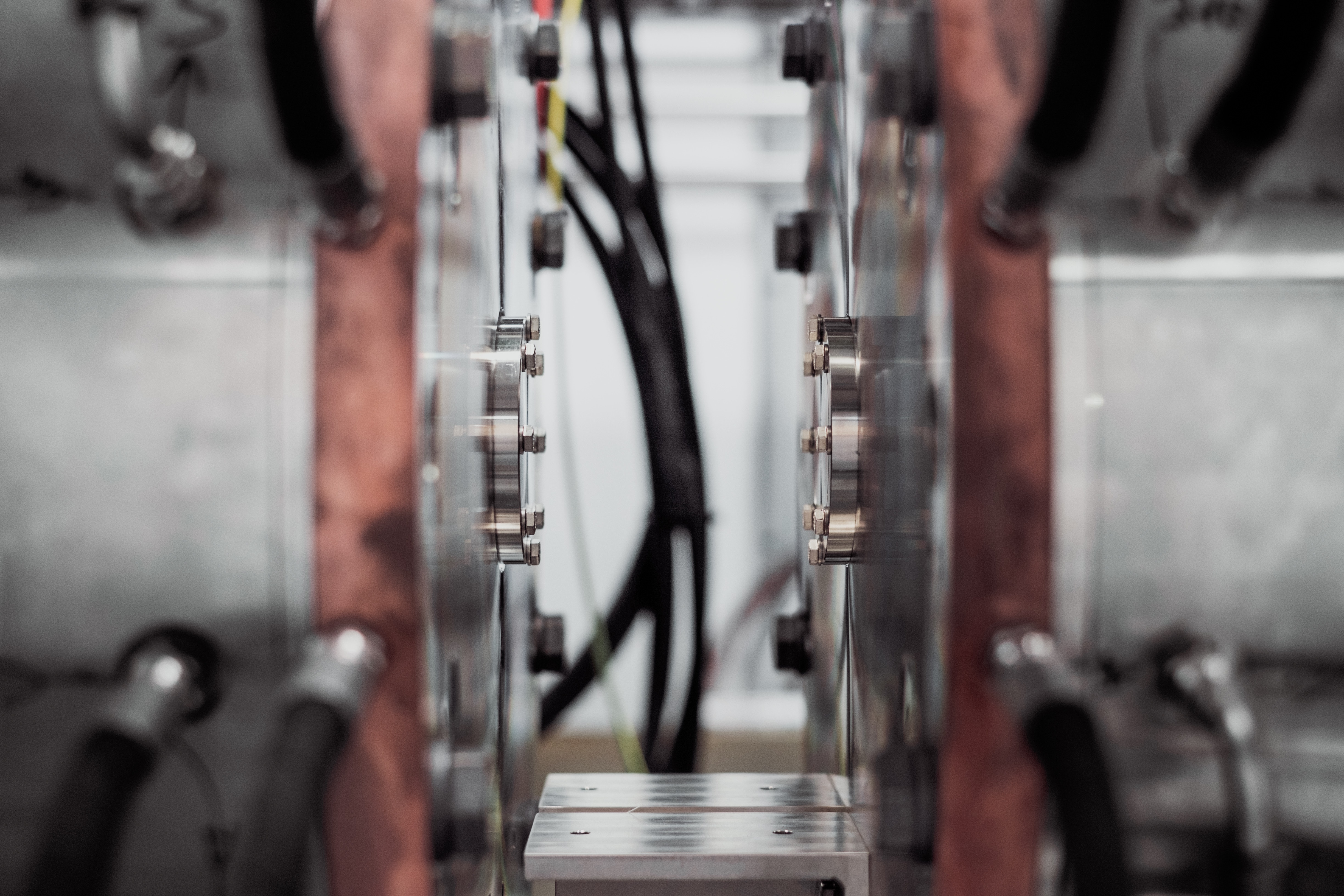

By design, NX creates a holistic system that combines all elements of the design process. This forms the foundation for NX’s game-changing additive manufacturing capabilities, which inherently require interdisciplinary capabilities. Additive manufacturing is great for producing unconventional parts as well as reducing resource costs.

Computer Aided Design (CAD) is essential for creating your ideal, optimized part. NX offers excellent tools in its design suite including convergent modeling, lattice structures (for lightweight designs), and design validation. Not only can users complete the CAD modeling in NX’s design suite, but they can easily transfer designs to the NX’s simulation suite and manufacturing suite. This supports a truly end-to-end workflow very efficiently.

Simulation is essential for verifying and optimizing the part. This allows for the correction of errors within the design process itself, which eliminates downstream issues.

After designs are validated, Computer Aided Manufacturing (CAM) fills a crucial part of the process: the physical creation of components via 3D printing. Unlike traditional manufacturing, this new process only requires the amount of resources needed to complete the specified design. Parts can now be cheaply produced at small-scale, and unconventional designs (such as those containing lattice structures) no longer pose the production challenges they once did.

NX’s CAD, simulation, and CAM capabilities weave together to enable users to design, verify, and produce components. NX users can create designs with confidence, knowing that NX can take them through the entire process of additive manufacturing, from ideation and design, to validation, to creation.

Additive manufacturing comes with a host of benefits, including:

- Unconventional parts and small orders can be created quickly and cheaply.

- The amount of material required to create a component is greatly reduced compared to traditional manufacturing, thus raising efficiency and lowering costs.

- Users can manufacture new parts when needed, reducing need for back-up components. Instead of a storehouse of back-up parts for machines, all you need is a 3D printer and the appropriate digital designs.

How will you leverage additive manufacturing in your design workflow?