How Siemens Real Estate leverages digital twin technology | CAD software for building information modeling (BIM)

Welcome to another recap of the Next Generation Design podcast for the episode: Digitalizing the Construction Industry with Building Information Modeling (BIM). You can watch the full video version of the episode below.

On this episode of the Next Generation Design podcast, our host Greg Arnot welcomes Thomas Reimann, Innovation Technology and Sustainability Expert at Siemens Real Estate and Derek England, NX Product Manager at Siemens Digital Industries Software to discuss integrating the BIM model with shop floor layout.

In this episode, you will learn more about the power of collaboration with BIM, how Siemens Commercial Real Estate incorporates Digital Twin technology, and what we can look forward to seeing in the future with regards to integrating virtual reality into the BIM workflow.

What you’ll learn about in this episode:

What is Siemens Real Estate?

Siemens Real Estate (SRE) is one of the world’s leading corporate real estate management. They care for all owned and rented spaces that Siemens uses, from offices to factories or even whole city districts like Siemensstadt Square. Thomas says that being part of Team Siemens means that digitalization and innovation is part of the DNA of the company. “We constantly try to drive new topics, be ahead of real estate trends, try new things, be Customer Zero, do things differently, dig into processes, and so on. We try to create together,” he says.

Utilizing BIM at Siemens Real Estate

Being digital-first, building information modeling (BIM) is incredibly important for SRE as it helps us combine the real and digital worlds, being a perfect foundation for building a digital twin. BIM is mandatory for all new construction for SRE, and is used throughout the operational phase of buildings as well.

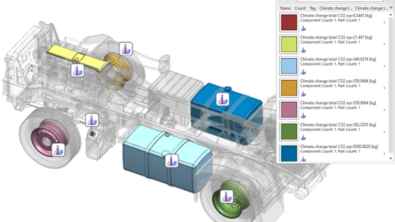

Greg asks Thomas about how SRE is using digital twin technology, and Thomas gives an example of the Digital Native Factory in Nanjing that was planned and simulated completely digitally. “We combined factory data, shop floor data, performance data, and even building data to create a complete digital twin of the building,” he explains. Though this project was a big success that even led to a Werner von Siemens award, they needed to improve their processes and make them more integrated so that they could scale and do multiple projects simultaneously.

The BIM and shop floor design and collaboration workflow

BIM and mechanical CAD are typically two separate design processes with separate teams, with BIM data owned by SRE and updated with help from facility managers, and shop floor equipment/planning owned by engineers on the shopfloor itself. This means that architects from Siemens Real Estate are responsible for typical structures such as walls, columns, etc. of the building itself and engineers are responsible for deciding where to position shopfloor equipment within the building. BIM data is first created and updated in traditional BIM software, then imported into NX where engineers will do the shopfloor planning of the equipment relative to the building plan. The shopfloor layout and designed is completed fully digitally.

After the first design review, edits need to be made. If an architect shifts a wall, the data from the BIM software needs to be handed back over to the engineers again by exporting it to the open IFC format. Then, the engineer will need to import and open the IFC file in NX, review the change, be aware of the change and adopt the shopfloor layout as needed. After updates have been made, the engineer must again export the shopfloor NX data to the IFC format to transfer it to the architects, who then import it all into Revit to review any issues or collisions and so on. These design reviews typically happen weekly or even daily, so this requires much transferring, importing and exporting of different data.

Challenges connecting BIM and CAD data for shop floors

The transferring, importing and exporting of data when changes are needed proves to be a challenge in the process of integrating BIM and CAD data. With the need to improve processes, collaboration and data integration, Siemens Real Estate connected with the Digital Industries Software side of Siemens. This led Thomas to Derek, and they discussed how to establish the connection between BIM files and shop floor planning and create a digital twin. This included working together on BIM data import to discover what works best for them, as NX allows you to preserve the BIM structure as an assembly structure, flatten the BIM structure into a single NX component or import the BIM data as a precise boundary representation or lightweight facet data.

With the collaborative process and different options for presenting BIM data in NX, Thomas outlines three of the main challenges they face in connecting the BIM and mechanical CAD worlds:

- Data format: BIM CAD data is stored in a single part file. In NX, data is in the form of components/parts and assemblies. BIM CAD workflows highly rely on BIM attributes for collaboration, so there was a need to preserve these attributes within NX.

- Positioning: BIM CAD workflows rely on everyone designing around the same project coordinate system and base points. This project coordinate system is essential when aggregating data from multiple CAD systems together.

- Complexity: Replicating the BIM structure within NX using assemblies adds a lot of complexity with long translation times, very large data sets and sometimes unnecessary parts (like doors or windows).

Elaborating on complexity, Derek notes that utilizing best-quality IFC translation options required hours for translation, thousands of NX parts and gigabytes of data. Part of this was due to that when importing the BIM data as IFC, each door or column that were essentially identical, would appear as individual, unique parts in NX as opposed to assembly instances. Whereas two columns that were the same other than height would be instances in BIM data, the two columns would not be instances in NX since they were different in shape. This posed a learning curve with importing BIM data into NX.

Thomas notes that another challenge in the design process includes different understandings from architects and engineers throughout the process, thus requiring multiple iterations to get to a common understanding, which slows down efficiency. Thus, they now begin any project with demand clarifications with documenting the engineers’ requirements for the shopfloor (such as floor size, ceiling heights, HVAC demands, etc.). With these requirements, an initial rough BIM model can be created and sent to the engineers who then make rough plans on where to place different equipment. They go through different iterations until they get the final building and shopfloor layout, adding more details each time.

As they have integrated CAD into the BIM workflow for shop floor layouts, Siemens Real Estate has worked through challenges as they come up. But Thomas says that they needed a more efficient way of importing data into NX, where ideally there wouldn’t need to be constant transferring back and forth, and that design updates would happen in real-time for both the BIM and mechanical CAD data. With all these traditional processes, companies like SRE need to develop new processes that allow the BIM and mechanical CAD worlds to work concurrently to create a complete digital twin.

Siemens’ plans for improving NX for BIM collaboration

Acknowledging SRE’s current challenges, Greg asks Thomas where he would like to see advancements in their collaboration processes. Thomas says that he’d love to interconnect both words, where “as soon as there is a change, for example, on the building side, the engineer gets an indication that there is a change and options on how to adapt to these changes, fully automatically and fully digitally; that would be my wish,” he elaborates. He would also like to see NX adapt to the BIM Collaboration Format (BCF) process. He concludes his thoughts with talking about VR, noting that while they are using it for visualization, simulation, collaboration and virtual decision-making already, our Immersive Engineering collaboration with Sony’s XR head-mounted display as well as the evolution of the Industrial Metaverse will help shop floor engineers even more. He hopes for the collaboration between Siemens Real Estate and Siemens Digital Industries to continue as they learn, adapt and drive further together.

Derek then talks about enhancements for NX that will benefit BIM workflows. He emphasizes Thomas’ point around Immersive Engineering, seeing it as an important part of design reviews and creation. He also says that we have plans to continue the work on improved translation, as direct translations can offer additional benefits over IFC. As of June 2024, NX Translator for Revit is available via token-licensing, enabling us to identify identical doors, windows, beams, etc. and create components as instances.

Derek also says we want to improve in performance as more detail will be included in models, and we need to be able to support these massive design projects. He concludes with collaboration being a focus for enhancement. While a simple interface that translates between disparate applications is not ideal for contractors and owner-operators, a solution that allows us to have a reflection of the shop floor and building together and immediately see changes is something that we would like to see. “We’d really love to see the ability to really integrate those two worlds and create some kind of associativity between those two,” he says, “We really want to be able to design and develop a single source of truth within NX.”

NX for BIM collaboration

At Siemens, we are committed to helping our customers improve their workflows. The NX solutions for BIM, including the NX for BIM module which allows you to quickly design buildings natively in NX, continue to address customer needs as it evolves over time. You can learn more about how NX helps industry-specific workflows like AEC on our website.

Continue listening to the Next Generation Design podcast.

Want to learn more about NX CAD software? Check out our website or try it for free.