The Future of Industrial Machinery Design is Here

Over the past several months, we’ve explored how industrial machinery companies are navigating a rapidly evolving landscape; one shaped by digital transformation, workforce shifts and the relentless demand for smarter, more sustainable machines. From computer aided design (CAD) in the cloud, to immersive engineering, value-based licensing and artificial intelligence (AI) assisting design, each innovation has brought us closer to a more agile, intelligent and connected future.

In a nutshell: The future of industrial machinery is here. Let’s review what that looks like and how to bring it all together into one integrated approach that continuously drives value across the enterprise.

Connected collaboration with cloud CAD

In our first post, we explored the power of the digital threads, a seamless flow of data across the entire product lifecycle, from design and engineering to production and beyond. A digital thread therefore provides a virtual backbone to a company’s operations. It can be customized to meet different user expectations; supplies a complete connection between a virtual machine mockup with the physical machine; and supports an open ecosystem where different software and tech-stacks can interact with one another without issue.

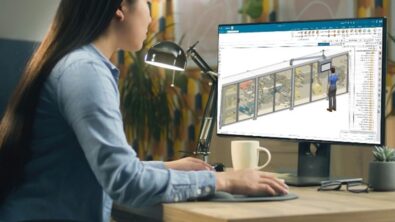

What makes a digital thread especially powerful though is when it’s used for cloud-based CAD. When designers migrate CAD workflows to the cloud, organizations can unlock new levels of collaboration, data management and flexibility. Specifically, CAD in the cloud empowers users to dynamically create, populate and share files across the company, driving real-time design collaboration. In turn, this significantly reduces the risk of miscommunications and mistranslations; furthermore, mistakes are caught earlier, reducing any potential costs that could have arisen with the introduction of hardware or other high-price assets.

CAD in the cloud realized through the digital thread thereby empowers machine builders and parts manufacturers to collaborate in real time, adapt to disruption and accelerate innovation.

From screens to headsets with Immersive Engineering

We then looked at how Immersive Engineering is transforming design workflows. Like several other markets, industrial machinery faces specialized labor shortages and must find unique ways to compensate. One such way is extended reality (XR) tools, where augmented, virtual and mixed reality tools can allow engineers to do more with less, thereby dramatically increasing their productivity and output.

This paradigm shift, from over-reliance on several flatscreens that zoom, pan and toggle between views, to gaming-style headsets that provide a completely interactive space, has completely redefined the design narrative: two or more engineers can virtually design a machine in-tandem to expedite the product development process; the infinite manipulation of space makes it possible to view every aspect of a machine for accuracy; the machine’s parts can virtually be checked against a virtual bill of materials to drive quality assurance; and so on.

In short, with XR technologies, engineers can increase their productivity with leaner teams, reduce errors, get products to market faster and lower costs as they conduct all work virtually.

Flexible access with value-based licensing

In our third post, we introduced value-based licensing, a smarter, more flexible way to access advanced CAD capabilities. Essentially, value-based licensing is a new approach to software access; rather than buying an outright license to use all features of a software, value-based licensing lets you pick and choose what features you have access to at any given time. In turn, organizations gain a customized CAD experience as they simply pay for what they need. It’s an ideal methodology for businesses with smaller budgets, or who wish to experiment with a software’s capabilities before committing to a full-service solution.

Value-based licensing works through a tokenization system. Different CAD features are assigned different token values based on their complexity and value. For example, basic operations like part modeling or assembly design require fewer tokens, while advanced capabilities like motion simulation, FEA analysis or automated manufacturing planning use more. With token-based access, teams can scale their toolsets without scaling costs.

Given all this information, the benefits of value-based licensing can be summarized as smarter financial management, enhanced engineering efficiency and a unique competitive edge as you can adapt to the market’s needs by adapting your capabilities on a whim.

AI-enabled design for smarter machines

Finally, we explored how AI is transforming industrial machinery design. Namely, there are three main forms of AI recognized today: narrow, general and super AI. Narrow AI is the only form to currently exist in modern society; it’s the type of AI that’s trained to complete specific small tasks, such as a spam filter catching and discarding bad emails in your inbox.

Beneath this broad categorization of general AI, there are two subfields primarily redefining the industrial machinery design space: predictive AI and generative AI. Predictive AI makes it possible to anticipate a design user’s needs and workflows by analyzing historical data and user intent. One good example of predictive AI is command prediction, where CAD software suggests commands based on how a user has used the tool in the past.

Generative AI, on the other hand, analyzes large datasets to create text, visuals or similar items. In practice, generative AI can suggest lines of code that optimize a design’s weight, structure, performance or other important characteristics. It can be further employed in relation to mesh modeling, providing important facets in the convergent modeling process.

From predictive modeling to generative geometry and mesh optimization, AI helps engineers reduce errors, accelerate development, and innovate faster.

Next generation design within industrial machinery

It is estimated that by 2050, manufacturing will be “close to complete automation,” according to the Society of Manufacturing Engineers (SME). Furthermore, by 2050, AI will influence 26% of global GDP – with an estimated 60% of current jobs requiring major changes to stay competitive, per findings in a 2023 report from PwC, McKinsey and the World Economic Forum. The very same report predicts that early adopters of AI and adjacent technologies could see 40% higher earnings.

Therefore, given the changing face of industrial machinery design that each of our blogs touched upon, it is of the utmost importance to weave all these facets together under one unified, technology-powered approach to stay relevant in the global market.

To take the next step in engineering design, organizations should opt for an advanced solution that connects every discipline through the cloud, integrates immersive with traditional engineering, offers reusable tokens for a flexible working environment and leverages AI as an auxiliary tool that supports yet never replaces designers. Siemens’ Designcenter is that solution.

Designcenter is a comprehensive product engineering suite tailored to the needs of industrial machinery manufacturers, combining:

- Designcenter NX, Designcenter X NX and Designcenter Solid Edge for scalable, interoperable CAD.

- Immersive Engineering for next-gen collaboration.

- AI-enabled design tools for smarter workflows.

- Value-based licensing for flexible access.

- Cloud-native infrastructure for global scalability.

For industrial machinery companies, this means:

- Speeding up design cycles by 20 percent

- Reducing design adjustment time by 30 percent

- Lower development costs

- Seamless collaboration across teams and geographies

- A future-ready platform that grows with your business

“The design and engineering capabilities in Siemens’ Designcenter suite enable us to document complex parts, components and 3D layouts more efficiently. This helps us streamline our processes and be more agile every step of the way.”

— Jan Griebner, Head of Research and Development, Tremonia Mobility GmbH

Build what’s next with Siemens Designcenter

Whether you’re designing complex machines, optimizing production lines, or reimagining service models, Designcenter is here to propel you to the forefront of innovation.

By unifying AI-enabled design, immersive engineering, and cloud collaboration in one powerful platform, we’ve created a solution that amplifies designer capabilities while reducing complexity.

Step into the future of industrial machinery design with Siemens Designcenter today!