Top 3 Tips for Machine Designers

Machine Design lays out a full top tips for machine design.

1.) Embrace Multi-Disciplinary Design Functionality:

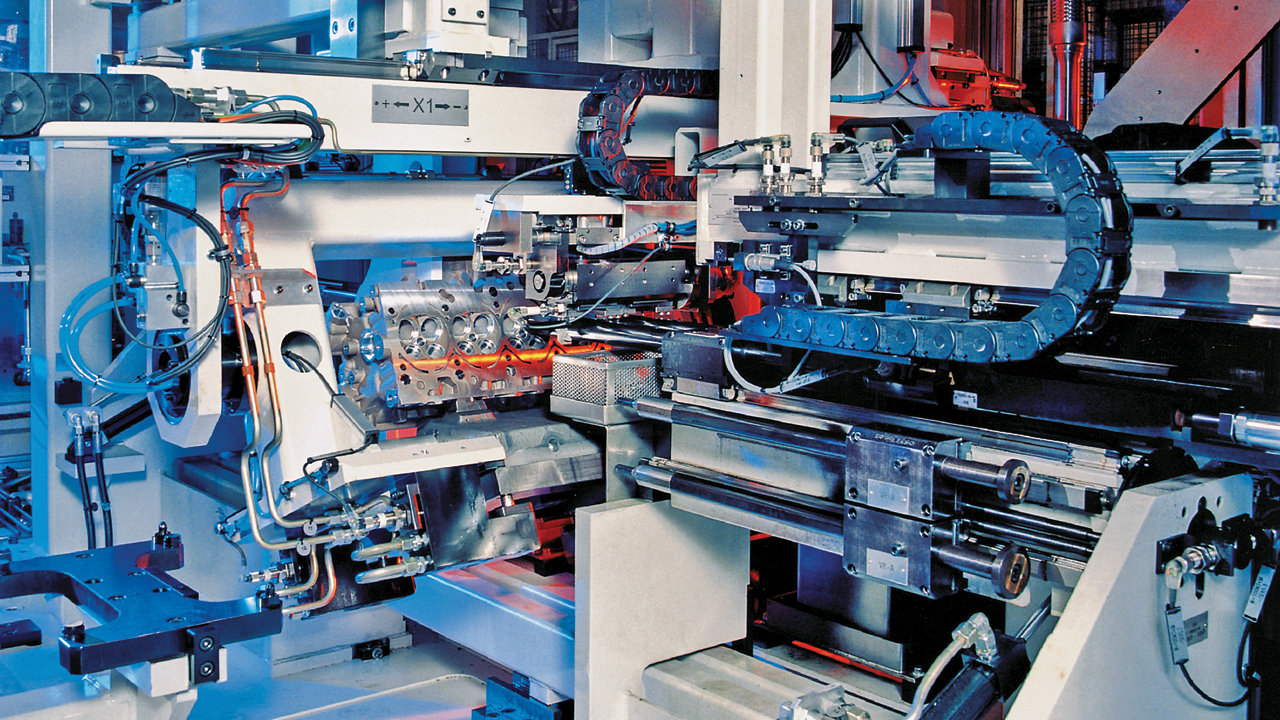

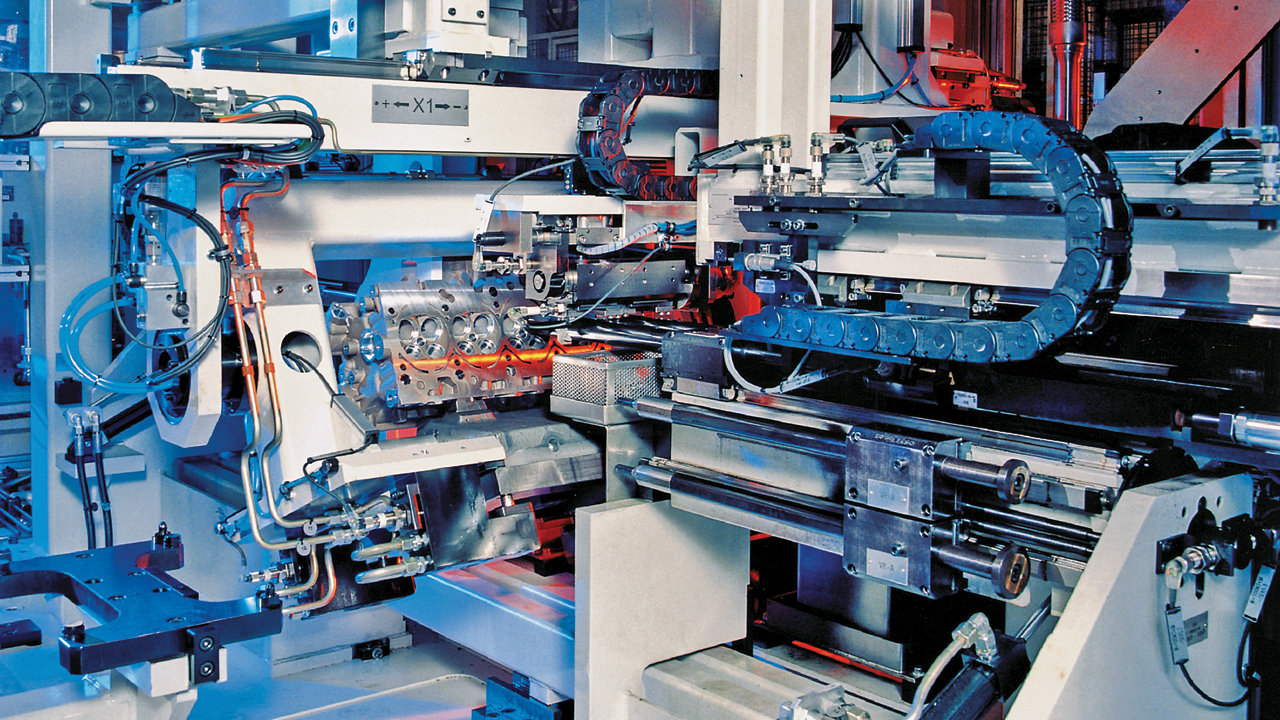

NX allows for multi-disciplinary engineering to reduce the time between your first concept to the delivered machine by integrating with other engineering groups. It offers a complete set of designer-level validation and fast design exploration tools. The technology breaks down the barriers between electrical, mechanical, and automation engineers. Mechatronics design continues to revolutionize the machine design process. It helps you design faster with higher quality, providing an end-to-end solution that enables multi-discipline collaboration, reuse of existing knowledge, reduced time to market, and better decision making at all levels from concept to production validation. This allows your company to move from 3D to Mechatronic the same way you moved from 2D to 3D.

Machines are evolving just as the industry is. Since it is nearly impossible to act on every aspect, you need to be able to use one tool for all your disciplines. The technology is out there and it is called NX. You get the benefit of quick evaluation of multiple concepts early in the design phase, as well as eliminate errors from data re-entry to allow for complete system validation. Leveraging solid models with true kinematics helps obtain a realistic demonstration of how the machine operates. Flexible design solutions provide an average of 30% shorter development time, as well as efficient construction through reuse. Users can also perform 3D analysis without leaving the CAD tool.

2.) Understand the Value of Additive Manufacturing:

The additive process allows you to re-imagine your products, re-invent your manufacturing, and re-think your business. You can add generative and additive capabilities to develop critical components that improve strength while removing weight. You can also quickly print long lead time or obsolete parts to support your customer base on a perpetual basis. Finally, you can provide valueengineering by combining expensive assembly components into a single additive part.

3.) Get Acquainted with Fully Collaborative Design Management:

There is no denying the value of providing PLM across engineering, manufacturing, and service operations connected to industrial IoT. This is because the level of technology needed is highly variable and can extend from standard products and configure-to-order all the way to engineer-to-order, where final product specifications are defined up front by the customer. In this case, you must decrease project engineering time as well as increase data re-use, eliminating mistakes through specification error.

NX provides a modular platform with a set of multi-domain solutions that allows a variety of operations to provide additional value at the assembly level and through part re-use. Configuration management is the key to profitability. With configuration management software, you have complete access to configurations across your organization, including custom views and BOM for each customer. Simulation tools provide results in hours rather than weeks.

| Read the report to get an insight into the Advanced Machine Engineering solution that enables to incorporate customization into the industrial machine design process. |

Have any thoughts? Suggestions on more tips to add? Let us know by leaving a comment.

Comments