University of Cincinnati prepares students for engineering careers by teaching NX CAD

On this episode of the Next Generation Design Podcast, our host Jennifer Piper talks to Dr. Sam Anand, professor at the University of Cincinnati (UC) and Director of the Siemens Simulation Technology Center about how UC utilizes NX and other solutions from Siemens Xcelerator to teach engineering students hands-on learning throughout their five-year program.

In this episode, he will help us understand the impact of the Siemens Simulation Technology Center on engineering education and research at the University. You will get to learn about Sam’s expertise and experiences in teaching digital manufacturing and design to students at the university level. And you will also hear more about using Siemens software and tools in the curriculum and the focus on solving real industrial problems through simulation.

Listen or read to the full episode: Integrating Siemens Software and Tools in Engineering Education

What you’ll learn in this episode:

How Dr. Sam Anand started his career in engineering

Sam studied Mechanics Engineering in India and a Master’s and Doctorate in Industrial and Manufacturing Engineering from Penn State. In 1990, he began his career at the University of Cincinnati to begin teaching. He has always been passionate in engineering since it allows us to be creative in solving new problems, with a big interest in manufacturing. He became a professor to be able to mix teaching, researching, interacting with industry, and bringing that back to the classroom.

UC Siemens Simulation Technology Center

The Siemens Simulation Technology Center was formed in 2016 with the goals of training students in the suite of Siemens software and infusing it into courses as they learn the fundamentals of engineering, as well as using the software for industry research contracts and bringing the learning back to the classroom. Currently, over 1400 students are exposed to Siemens software throughout different courses. In addition to just within the classroom, Siemens software is used across other parts of the University such as the new Industry 4.0/5.0 Institute and the Digital Futures lab facility for interdisciplinary research.

Siemens software at UC

Sam talks about the suite of software used to teach students, such as Simcenter, STAR-CCM+, MindSphere, Mendix, and more. The software is integrated into over 20 courses where it is used in homework, projects and demos. Students come out of the course with knowledge of the software and how to use it in their future jobs in the industry.

Sometimes, Siemens experts give lectures and presentations, or people industry will show the value of using Siemens software. Through the multi-pronged approach in learning about how to use and implement software in their jobs, students benefit from bringing software knowledge to their co-ops and full-time jobs, making for a smooth transition from school to work.

Teaching Siemens’ NX to university students

Through the academic partner program, students get free access to software that they can use on their personal computers. UC has also developed online training that people can access outside of the classroom. As students learn NX, they may take the NX certification course offered from Siemens.

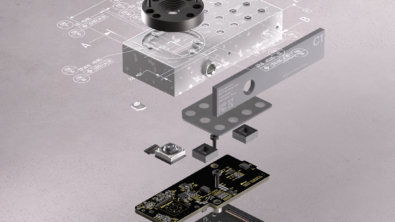

NX is used throughout student curriculum in all five years of the undergraduate experience. Software is not learned in one course and forgotten. In every course, students learn a software and build upon that learning, integrating it with other solutions through the interoperability of NX. NX CAD is needed in every course where a product is needed for analysis, whether they are using Simcenter, STAR-CCM+, or NX for manufacturing. UC also leverages the NX Application programming Interface (API) to build apps that they use to work with NX Additive Manufacturing.

Sam talks about how NX is taught in stages since it is a complex software that has many capabilities. They start with teaching simple modeling which helps in many aspects of an engineering job, and as they go through their coursework they ramp up to learn the more complex features, which takes time. Their learning culminates in senior design where students work on an industry problem. They use NX for product modeling and other Siemens solutions to do analysis.

Sam highlights the concept of generative design, where there are many options for a design that one can choose from, “One of the things is there is no one optimal design, there are sub-optimal designs, and there’s a suite of other designs that are close to optimal that one may want to pick.” He compares generative design to life itself, where there is no one solution but a suite of solutions in which different are applicable in different situations so you need to know how to generate those solutions and go from there.

He emphasizes that students need to be engaged, they need to do projects that are relevant to what they are learning and how to apply it to industry problems. They learn the basics and are given real-life examples to apply their learning of Siemens software. Gone are the days of just writing and running equations on pencil and paper.

Research projects at UC using Siemens software

UC does a range of projects in different industries, from aerospace to automotive to medical. One area that UC does research projects on is additive manufacturing design. They use NX for design, analyzing design, write their own graphic user interface within NX, and write their own manuals for algorithms for analyzing a part design and finding process parameters or problem area. They also do layer-by-layer analysis of parts.

Another area they work in is IIoT with gathering machine data automatically and pulling it into the cloud and doing analysis with that data to see if changes are needed. They also integrate AR (augmented reality) and VR (virtual reality) into their projects, for example being able to see parameters of the machine data on an iPad as you walk up to the machine.

A specific project they work on with the medical school at the University is using additive manufacturing for cranial flap repair for neurosurgery. This involves collecting CT scan data and analyzing it to make a 3D-printed part.

The University of Cincinnati also works with The Digital Manufacturing Design Innovation Institute. This institute began in 2016 and is based at University of Illinois Labs in Chicago, Illinois. It is government-funded to enhance the manufacturing competitiveness of the United States. The University of Cincinnati has done multiple projects through the initiative, one of which won an award for Best Paper at the North American Research Conference. Through their research projects they have worked with GE Global Research, University of Illinois Urbana-Champaign, Faurecia, Raytheon, Boeing, Siemens AG, and other

To anyone trying to learn NX, Sam offers advice: “Be patient. There is a learning curve. Once you get past a certain point, it will get much smoother and you will start enjoying it — the reason is now you’ll start exploring the features of NX, which are tremendous features… Once you master those things, you will start to enjoy it because now you can see the power of NX and the associated software to do so much analysis that 20 years ago people could not even imagine.”

Connect with Jennifer on LinkedIn

Continue listening to the Next Generation Design Podcast here

Want to learn more about NX CAD software, how to learn NX, and the NX Certification process? Check out our website or explore about NX student resources.