Immersive engineering

Welcome to the Designcenter NX blog! If you happened to land here looking for the Minecraft mod re: Immersive Engineering, we’re sorry to disappoint—we won’t be covering pickaxes or power lines this time ‘round. THAT SAID, we’ll be diving into something just as creative—but with real-world implications: immersive engineering technologies.

Unlike Minecraft, this isn’t about creating a fictitious world—it’s about how augmented reality (AR), virtual reality (VR), and mixed reality (MR) are currently transforming design, simulation, and collaboration for engineers in the real world.

Immersive Engineering has now become an essential tool of Industrial Metaverse. A space where the Digital Twin mirrors what is—and eventually will be—be brought to life within the virtual canvas of Designcenter NX. Keep reading to learn more about this next evolution in engineering…

What is Immersive Engineering?

Immersive engineering speaks to the use of immersive technologies—such as AR, VR, and MR—in real-time engineering practices. These technologies enable engineers to visualize, simulate, and interact with designs in a virtual environment, enhancing understanding and collaboration across multidisciplinary teams and workflows. Thereby reducing physical prototypes and optimizing spending while promoting smarter engineering workflows.

Applications include:

- Virtual prototyping

- Immersive simulations for training

- AR overlays for maintenance and repair tasks0

- MR for blending the two in collaborative workflows

Capabilities of Immersive Engineering

Virtual Prototyping and Simulation

Build and test digital twins at full-scale, walk through designs, and reduce physical prototyping costs.

Collaborative Design Reviews

Bring dispersed teams into the same immersive design review with shared annotations.

AR for Assembly and Maintenance

Overlay instructions in real-time to reduce errors and training time.

Virtual Testing & Validation

Virtually simulate stress, wind, and thermal conditions on designs before physical production.

Remote Monitoring via Digital Twin

Monitor and optimize real-world systems with live-updates of digital twins.

3D Visualization & Human Interaction

View CAD models in context—evaluating ergonomics and optimizing workspaces

The Future of Engineering is Immersive

The line between digital and physical workspaces is blurring. Engineers now have the ability to collaborate in shared virtual spaces, test prototypes in safe environments, and accelerate product development and time-to-market. This is no longer science fiction —it’s becoming the new standard in engineering.

Applications of Immersive Engineering

- Remote field operations

- Architecture and construction

- Product design and prototyping

- Manufacturing workflows

- Engineering education

Benefits of Immersive Engineering

Enhanced Visualization and Design

Better spatial awareness, faster iteration cycles.

Improved Collaboration

Remote teams work together seamlessly.

Realistic Simulations

Safer, faster, cheaper than physical testing.

Training & Education

Risk-free, hands-on learning.

Problem Solving

More intuitive human + machine interfaces, featuring improved AI commands and reasoning.

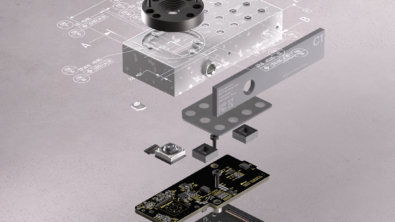

Immersive Engineering in Product Design

When CAD meets VR/AR, engineers can evolve their engineering by stepping inside their models. This not only accelerates decision-making but reduces costly prototype redesigns and enables collaboration with stakeholders in more natural and intuitive ways.

Watch the video below to see how industrial engineers use Siemens’ NX Immersive Designer to optimize a racing bicycle’s performance specifications.

FAQ: Immersive Engineering questions

Is Siemens’ Immersive Engineering the same as the Minecraft mod “Immersive Engineering”?

No. The Minecraft mod is a game extension, while Siemens’ Immersive Engineering refers to advanced AR, VR, and MR tools used in real-world engineering, product design, and simulation.

What Siemens software supports Immersive Engineering?

Siemens offers a portfolio of immersive tools. NX Immersive Designer lets engineers step inside CAD models for collaborative reviews and virtual prototyping. NX Immersive Explorer provides lightweight 3D model viewing for non-CAD stakeholders, making design intent accessible across the organization. On the simulation side, Simcenter XR tools bring immersive visualization to stress, thermal, and acoustic analyses—helping teams understand performance results in context. Together, these tools connect design and simulation in immersive environments that speed decision-making and reduce the need for physical prototypes.

How does immersive engineering connect to the Industrial Metaverse?

Immersive engineering is a key enabler of the Industrial Metaverse, where the digital twin mirrors real-world systems and allows engineers to test, validate, and optimize designs virtually before production.

What industries benefit most from immersive engineering?

Automotive, aerospace, architecture, manufacturing, and even sports engineering (like cycling and motorsport) are leveraging immersive technologies to improve design speed, safety, and collaboration

How can I try Siemens’ immersive engineering tools?

You can start with a trial of Siemens DesigncenterX NX and book a demo of its Immersive Designer module. Visit the Siemens Designcenter page to learn more and request access