Redefining Electronic Design Automation, an IC Perspective

In January, Mentor will become Siemens EDA and this is exciting news for our EDA customers. Siemens enables us to bring high levels of investment in research and development, to build new products, and to acquire best-in-class electronic design companies. Mentor has always pioneered digitalization of electronic design and Siemens brings world-class digitalization to big systems like planes, automobiles, factories, and cities. Connecting electronic design to big systems is the vision for our customers.

Around the globe almost every industry is redefining themselves through digitization. And, as you know, the IC is the heart of digitalization.

If you look at the business press these days, it’s rare to not see a mention of digitalization, digital world, digital enterprise, or the digitalization of everything. And I think that’s because companies are looking to leverage semiconductor technology to change their business models, logistics, and finance, driving an incredible opportunity for the semiconductor landscape. Whether it’s startups or large system houses creating internal design teams, we are seeing new players in the IC design market every day and it’s clear that will drive tremendous growth in the EDA business.

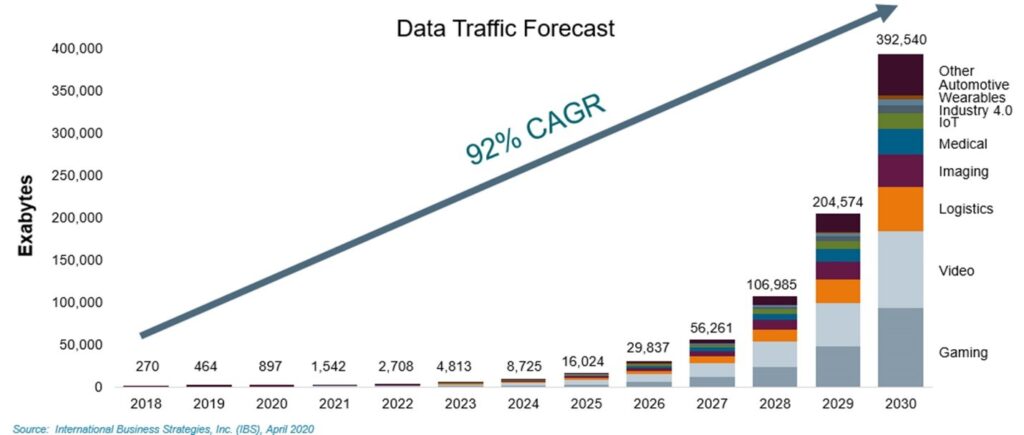

One way to see this is to take a look at the forecasting for data traffic which shows a 400X increase over the next few years. Whether the end market is a product in the gaming, video, IoT, automotive, or medical sectors, those markets are projected to be larger than the entire data traffic today!

It’s an amazing opportunity because that data needs to be processed and transmitted and those systems all rely on semiconductors.

In this large system scale, it is no longer sufficient to simply create and verify an IC, which in itself is a very complex process.

What is needed is a digital twin that can create, verify, validate, and simulate the entire electronic system running real software and interacting with the physical world. Designers need to not only ensure that their devices operate per the specification, but also ensure performance characteristics when running application software in the system context.

The digital twin redefines EDA

For over 35 years, IC designers have created a digital twin to manufacture their chips. But the digital twin Siemens EDA offers goes much further.

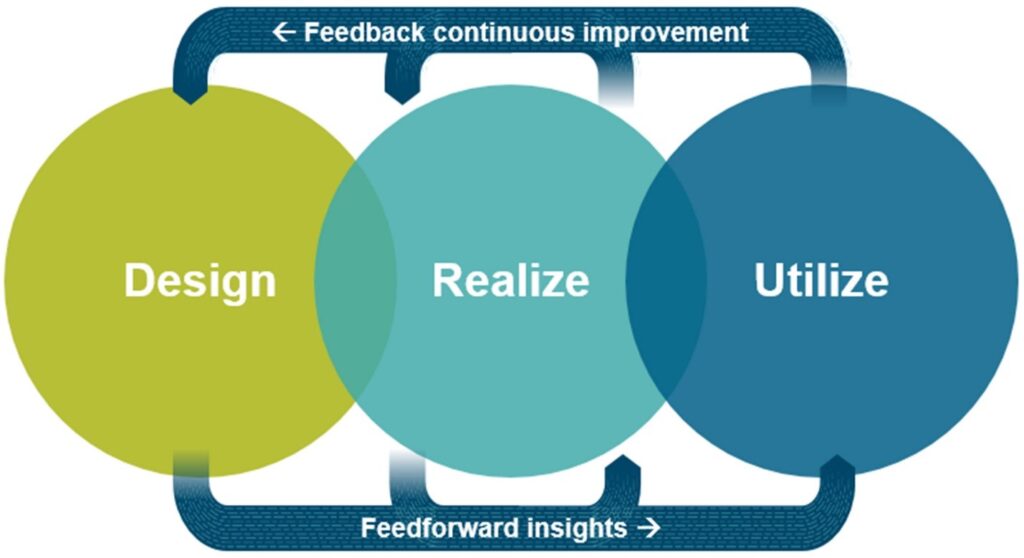

There’s not just a digital twin of the design that you can simulate. There’s also a digital twin of the manufacturing process to realize the design and there’s a digital twin of the device itself being utilized. These are all tied together in a way that allows us to enable feedback for continuous improvement from downstream and feed insights forward. With the product actually operating out in the field, issues can occur. That data can be fed back to the matching design digital twin that we can use to either improve the design or even send out a software upgrade to the product in the field.

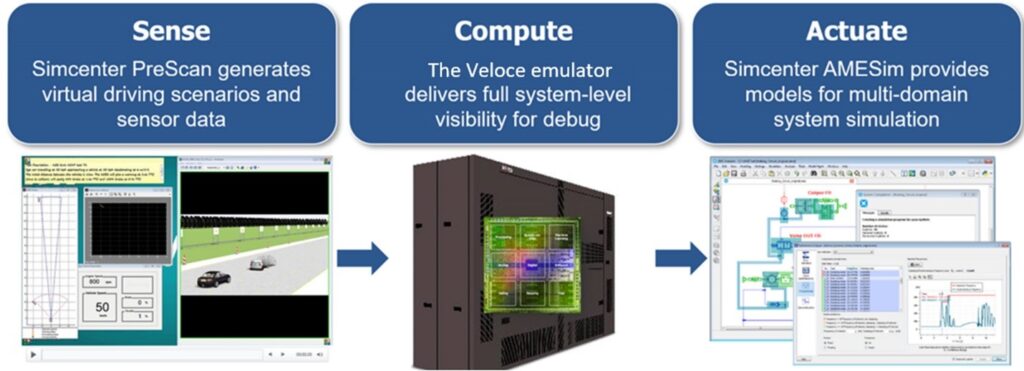

PAVE360 is a great example built on the digital twin concept. It is a complete autonomous vehicle verification and validation environment modeled at the system level that represents a twin image of the physical vehicle and its driving surroundings.

This digital twin combines Siemens EDA solutions with tools from Siemens Digital Industries Software. Simcenter PreScan generates driving scenarios and the associated sensor data, which are fed into a model of the vehicle’s E/E architecture and compute system running on the Veloce platform. Simcenter AMESim provides a multi-domain mechatronic system simulation platform to form a closed-loop environment that includes mechanical, electrical and hydraulic subsystems. Pre-silicon validation of an autonomous vehicle design is a real possibility today.

Because Siemens Digital Industries Software is the leader in the market, we can explore acquisitions that together with our tools, can offer the industry a unique digital twin. We caused a few eyebrows to raise within the verification community when we acquired Sarokal. At the time, it looked like a strange match. What that community did not figure out at the time was that Sarokal is the leader in 5G testing and has a seasoned team of people that have work closely with leading telecommunication companies to provide hardware and software solutions for fronthaul system testing. But, the key to these 5G telecommunication products is design and verification of custom SoCs, and that is where we shine.

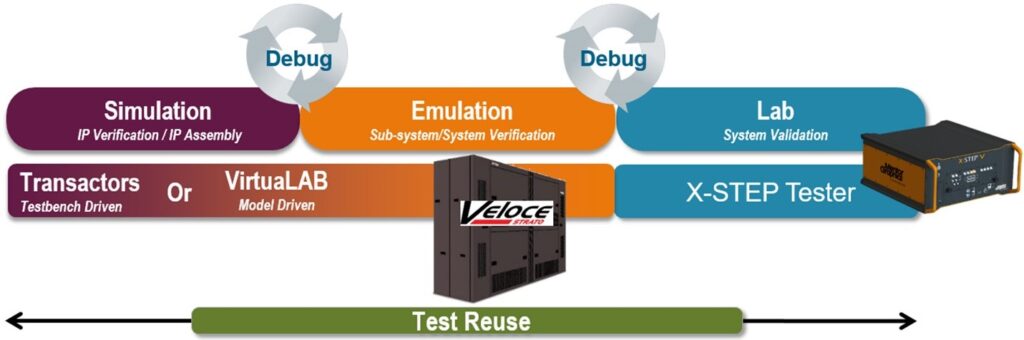

5G SoCs demand a new verification approach that meets the challenges of the exponential rise in required tests driven by the flexibility and configurability possible in the 5G radio access network. We offer a unique digital twin for the SoC design and verification flow for pre- and post-silicon. This bi-directional flow means that even when silicon is available, you can reuse tests in Veloce Strato to ensure that the system works as designed. When the system is available in the lab, you can run the same tests using X-STEP. With X-STEP, partners can exchange fronthaul test configurations in an executable format. This enables ecosystem-wide cooperation, thorough verification, and interoperability between devices from different vendors.

It is an exciting time to be in EDA. Providing digital twins is incredibly complex, but we view complexity as an opportunity to leverage our vast portfolio of products to meet the challenges of electronic systems today and tomorrow.

Comments

Leave a Reply

You must be logged in to post a comment.

This Siemens EDA news is fantastic! Connecting electronic design to big systems via digitalization is so powerful. It just shows how critical good guides are, whether for complex engineering or even gaming. For me, a solid Kingshot Guide has totally helped me conquer my current intricate game!