Five ways Opcenter reduces TCO for medical device manufacturing

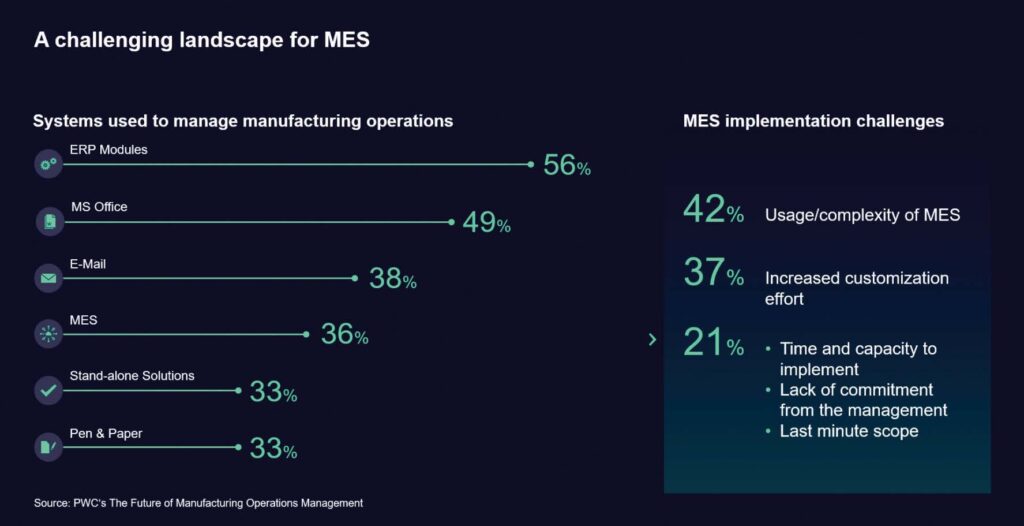

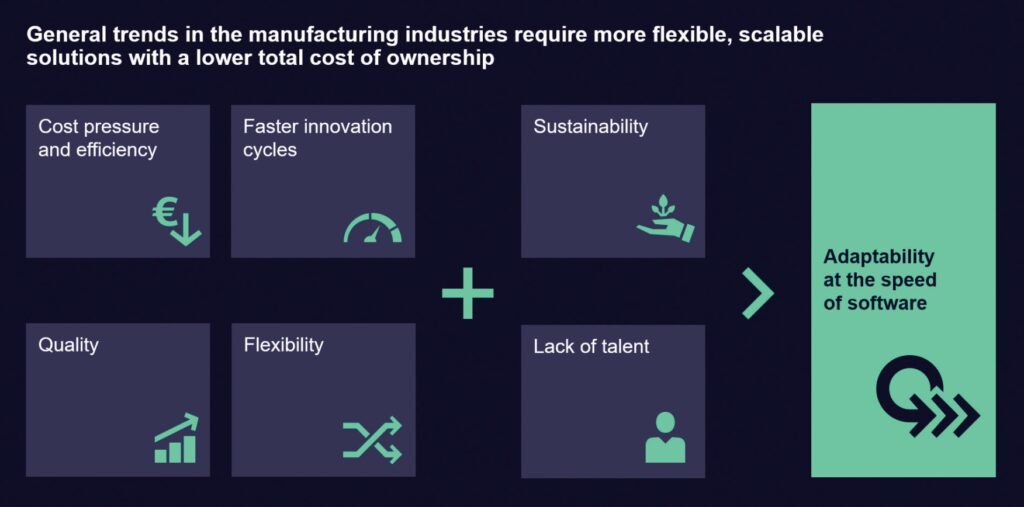

The cost of deploying and running a manufacturing execution system (MES) for medical devices depends not only on functional capabilities but also on what it takes to support the software and keep it performing at a high level. It’s this total cost of ownership (TCO) that’s a main point of comparison when it comes to machines and equipment for your production floors.

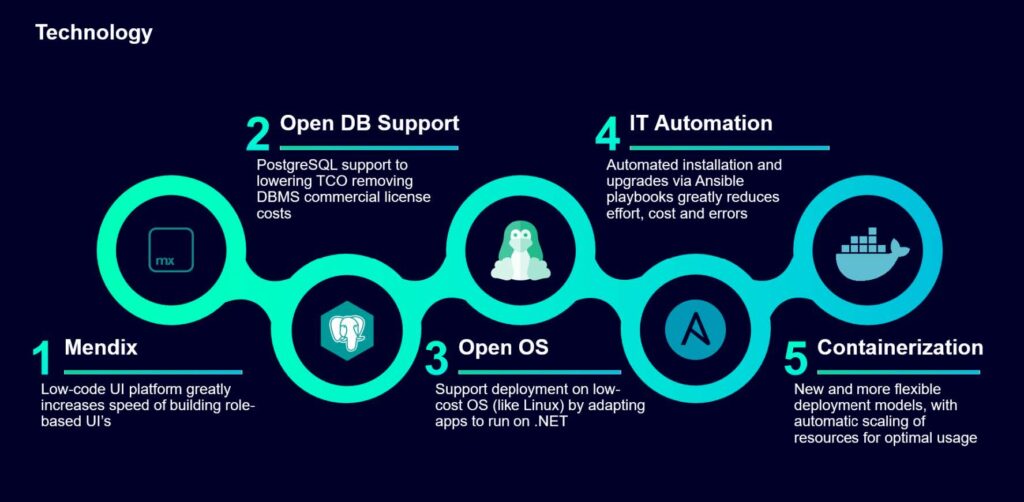

The Siemens Opcenter MES solutions portfolio has been designed with TCO in mind. We’ve identified five digital elements that ensure MES operations for medical device manufacturers are fully supported, constantly available, easily maintained and seamlessly upgraded as operations evolve and grow.

1. Low-cost flexibility with Mendix

Siemens offers an economical approach to MES flexibility with Mendix, our low-code multi-experience development platform. As products, processes and personnel change, Mendix enables you to easily adapt the UX of each team member to continuously optimize their productivity while leaving the core MES unchanged.

With Mendix, you don’t have to wait on highly skilled IT specialists to personalize new connections to needed data. Instead, Mendix helps to customize Opcenter templates with a few simple steps using low-code assembly tools.

- Snippets and widgets simplify and speed up screen creation

- App services provide domain-specific sets of capabilities

- Connectors enable users to extend workflows and experiences

2. Controlling data storage costs with open database support

One of the biggest costs associated with MES deployments is the database. Since medical device manufacturers typically have lower-volume production and limited automation, TCO could be reduced by using an open-source database.

That’s why Opcenter supports open-source PostgreSQL, which can lower the cost of database licenses and support by 70 to 85 percent. For many companies, this translates into a six-figure cost reduction.

3. Flexible system architecture and operating system options

A key TCO-reducing feature of Opcenter is that a manufacturer can serve multiple sites or factories while deploying the system only once in a centralized hub. Even geographically dispersed sites can be served by this multi-plant architecture.

To expand user options beyond Microsoft® Windows, Opcenter will now also support open operating system Microsoft .NET framework for deployment on lower-cost systems like Linux.

4. Automated software integration and upgrades

To reduce the costs of software installation and production downtime, Siemens has developed Ansible playbooks, which are scripts that enable a headless installation mode. This IT automation simplifies and expedites the process and reduces errors. Implementation can decrease installation time to as little as 30 minutes.

In addition, we’ve released an out-of-the-box (OOTB) tool that enables no-code creation of automated tests. Using dedicated documentation and sample scripts, continuous integration / continuous deployment (CI/CD) pipelines are fully supported, enabling project development teams to easily set up their infrastructure for automated build, deployment and test activities.

5. Improved efficiency with containerized, automated installation

A traditional MES installation model deploys the full software solution in a monolithic stack. However, replicating the full image, including the operating system and all installed software, is expensive and has a heavy digital footprint.

To reduce this element of MES, Siemens is modifying our system architecture to employ containerization and modularization. We take the key components of our application and break them apart so that each one can be deployed independently as an individual service.

- An application server executes all transactions, processes business logic and tracks execution success or failure.

- A notification server sends alerts to the user interface (UI) when certain events occur.

- A security server manages access to application deployment and deployment of master data.

Containerized, automated installation improves efficiency, which translates into additional reductions in TCO.

Learn more about MES TCO for medical device manufacturing

Siemens strives to provide the best MES value, which means we keep working to enhance the core capabilities of Opcenter solutions for medical device manufacturers. For greater detail of our five elements of TCO, read the full white paper. As part of the Operational Excellence for Medical Devices portfolio, Opcenter MES empowers manufacturers to be ready to efficiently produce high-quality, fully compliant medical devices through an integrated digital system. Our solutions help companies of all sizes leverage digital systems to produce innovations that meet tomorrow’s challenges.