Part 2 of the integrated ship design & engineering series: Driving efficiency with multidisciplinary design

Multidisciplinary design is redefining how shipyards build the vessels of tomorrow. Modern shipbuilding demands speed and precision. Vessels must meet sustainability goals and integrate new technologies while managing growing design complexity. Every innovation adds more data and coordination across distributed teams. Managing that level of collaboration requires more than connected tools. It calls for a shared environment where every discipline designs, tests and communicates in real time.

When disconnected domains slow development

In many shipyards, each discipline still operates within its own software and processes. Structural engineers build the hull; mechanical teams handle propulsion, and electrical experts design control systems without any of them having visibility into one another’s work. The result is missed dependencies and late-stage clashes that delay delivery.

Even small design changes can ripple across the program. Adjusting a bulkhead might alter pipe routing or cable runs. Without real-time visibility between domains, resolving these changes becomes manual and time-consuming. Legacy methods, even when digital, still create friction.

How does multidisciplinary design help shipyards stay ahead of complexity?

Multidisciplinary design brings every discipline into one collaborative environment. Within this shared digital twin, teams can:

- Use common standards to align work across domains

- Visualize how structural, mechanical, electrical and production systems interact

- Keep data consistent from concept through detailed design

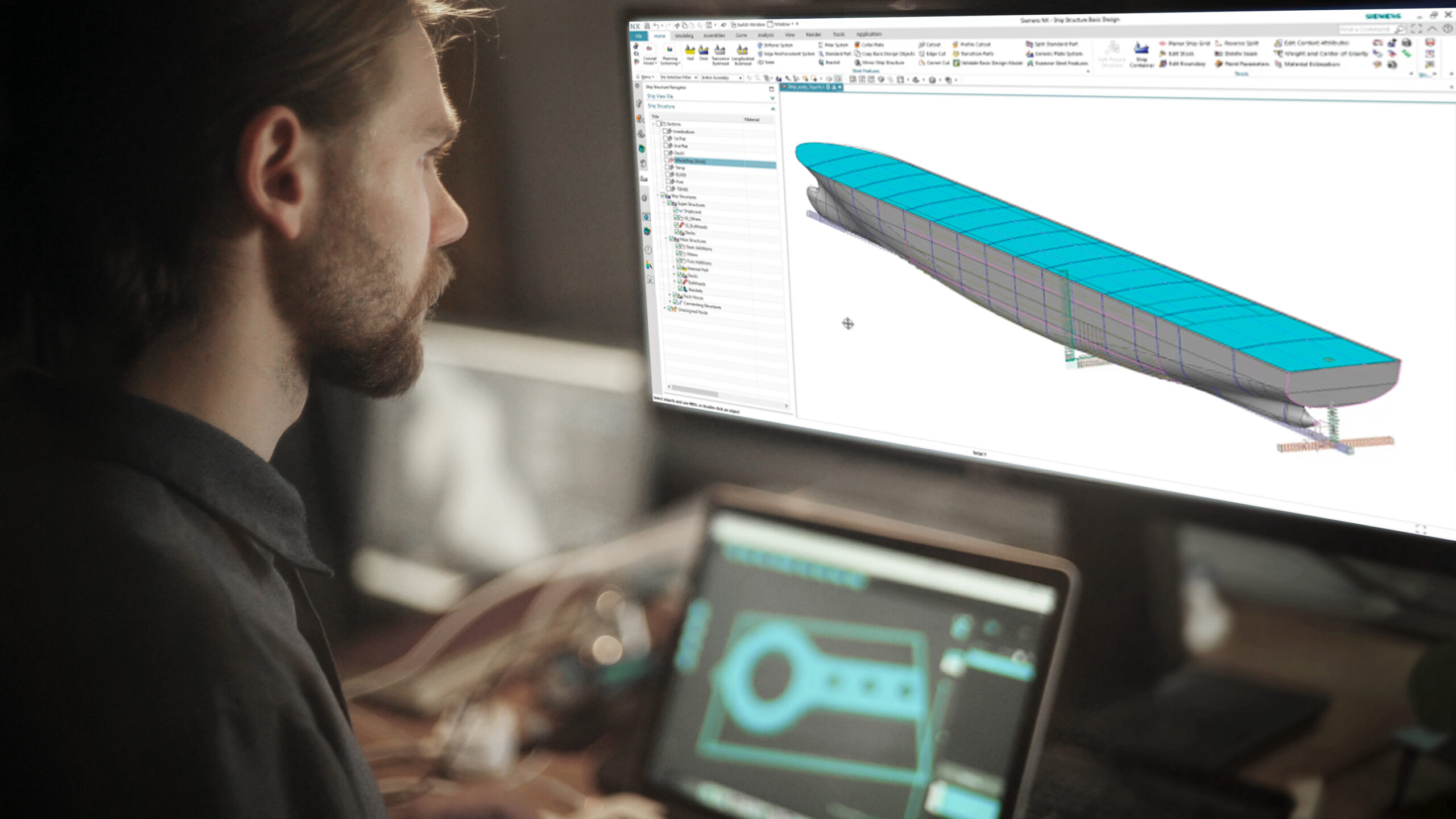

With NX as part of the Siemens Xcelerator business platform, shipyards can achieve this integration. The platform connects every tool and dataset in one digital environment, creating a comprehensive digital twin of the vessel. Engineers can model structures, route piping, simulate performance and evaluate manufacturability within a unified workflow that keeps data synchronized and accessible throughout development.

While cross-domain integration ensures information flows between systems, multidisciplinary design ensures the people behind those systems collaborate within a shared model.

When design intent, simulation results and production data exist in one space, teams can identify conflicts early and make decisions faster, reducing rework before manufacturing begins.

What scalable collaboration really looks like in shipbuilding

A connected design environment lets distributed teams operate as one, regardless of location. Changes made in one domain automatically update across others. Engineers can analyze performance while designers check manufacturability without waiting for handoffs or manual updates.

This visibility also strengthens partnerships. Shared access to accurate, current data keeps everyone aligned on the same version of the vessel. As projects expand, the environment adapts to include new disciplines, suppliers and regulations without adding complexity.

Beyond design to production readiness

Integrating design and production into one digital space bridges the gap between engineering and the shipyard floor. Manufacturing teams gain early insight into design intent, helping them plan production before handoff.

This alignment removes redundant work and accelerates preparation. Linking design and manufacturing data enables shipbuilders to move from concept to completion with fewer errors and shorter lead times.

Building a foundation for innovation

Multidisciplinary design goes beyond efficiency. It creates a framework for ongoing improvement. Within the Siemens Xcelerator ecosystem, shipyards can scale securely, integrate new simulation tools and extend their digital twin capabilities without disrupting existing workflows.

The result is an agile, future-ready shipyard where knowledge flows easily, innovation advances faster and every vessel benefits from continuous learning.

Stay tuned for part 3, which explores how simulation-driven design helps shipyards achieve efficiency targets and gain early insight into vessel performance.

Comments

Leave a Reply

You must be logged in to post a comment.

This article is really interesting! It’s great to see how technology can improve efficiency in shipbuilding. Siemens Xcelerator platform sounds like a game-changer. I wonder if it can be applied to other industries too!