Adopting a digital ship construction strategy – Part 1: Integrate engineering and manufacturing for smarter builds

In this series, we explore how connected, data-driven solutions are transforming ship construction. In this three-part series, each post will tackle a critical opportunity to improve collaboration, reduce risk and build smarter. Topics include:

- Connecting engineering and manufacturing with a digital backbone

- Improving process planning and quality management

- Optimizing shipyard strategy with a virtual shipyard approach

Disconnected processes cost you more than you think

Shipbuilding is one of the most complex forms of manufacturing, yet many shipyards still operate with disconnected engineering, building and logistics teams. Communication gaps, manual data transfers and version control issues aren’t just nuisances, they’re liabilities.

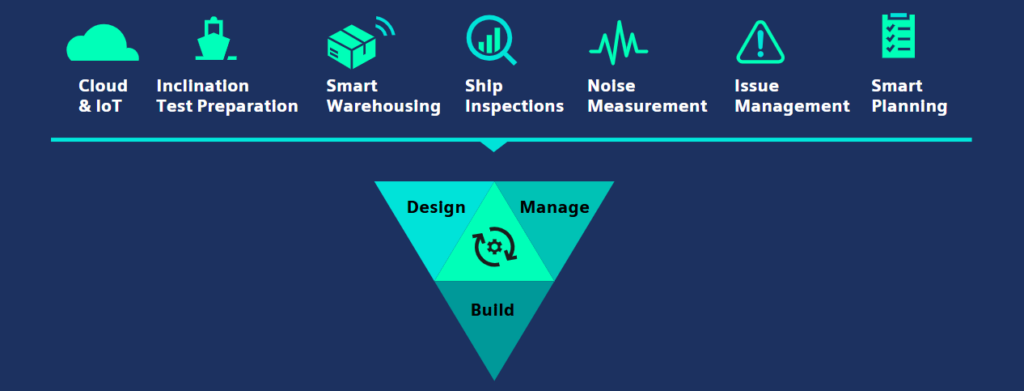

A connected digital backbone with PLM

Connecting your engineering, resource planning and manufacturing teams with a digital backbone powered by product lifecycle management (PLM). PLM is more than just a document control system. It’s a centralized hub that unites critical data and processes across the enterprise.

When integrated with enterprise resource planning (ERP) systems, PLM enables shipbuilders to:

- Link bills of materials (BOM), design files, quality data and procurement activities in real time

- Reduce costly errors caused by outdated or duplicated data

- Eliminate manual handoffs between teams

- Access live progress updates anytime, anywhere

“Isn’t PLM just for engineering?”

That’s one of the most limiting assumptions in shipbuilding today. PLM isn’t just for managing CAD files or design revisions. It’s the connective tissue between engineering, manufacturing, procurement and quality. When PLM is used only within engineering, you miss its full potential. Implementing a PLM backbone across your organization enables real-time visibility for production teams, streamlined handoff to procurement and lessons captured to inform future builds.

Seamless collaboration from design to delivery

PLM is the engine behind true collaboration. With Siemens Digital Ship Construction, powered by the Siemens Xcelerator portfolio, shipyards can bridge every phase of ship construction —from concept to delivery.

By integrating your engineering and manufacturing data through a digital thread approach, you gain real-time visibility, streamline decision-making and build smarter, ensuring your ship is built right the first time.

What’s next in the series

In upcoming posts, we’ll explore:

- How to focus on manufacturing process planning and quality management

- Why optimizing your shipbuilding strategy with a virtual shipyard helps future-proof your business

In the meantime, you can explore more resources and FAQs here.