Reduce heavy equipment downtime through accurate service planning

When you think about a service operations strategy for heavy equipment, the first thing to comes to mind is likely IoT, connected devices and predictive maintenance. But have you put the same thought into how to improve and optimize the actual serviceability of your heavy equipment?

In recent years equipment manufacturers have begun focusing on how to improve the manufacturability of their products and how to evaluate and plan for manufacturing earlier in the lifecycle to eliminate issues and shorten product launches. Few OEMs apply similar improvement concepts though for servicing the products – enabling earlier service planning and validation that results in first-time service rate improvements, reduced asset downtime, and customer satisfaction.

A comprehensive service lifecycle management (SLM) strategy

So, while a predictive maintenance strategy may help you identify problems more efficiently, have you considered the following:

- Can you quickly understand the service impact related to product changes, customer asset configurations or regional spare part differences?

- Is your heavy equipment optimized for service with early input from the required stakeholders?

- Are you able to quickly evaluate the overall service needs for a specific product?

- Do you have a clear understanding of the tasks and resources required to complete a defined scope of service?

- Are you able to optimize the performance of assets with knowledge of related service requirements?

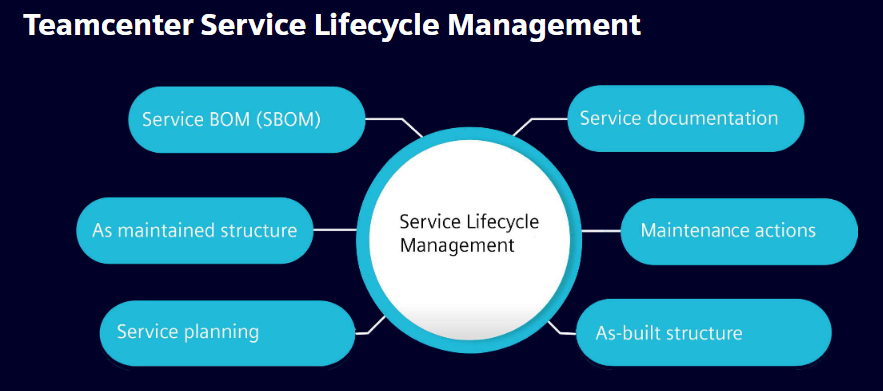

While connected assets with a predictive strategy is still important, it’s only one part of a comprehensive service lifecycle management (SLM) strategy. As the complexity of your heavy equipment increases, optimizing the serviceability of your products and efficiently managing changes will only become more critical.

How a lack of data continuity affects servitization

The details of what needs to be done to maintain a physical product is often captured in disconnected documents such as service manuals or repair procedures. This is frequently based on generalized information and does not necessarily represent the requirements of a specific physical asset. Or worse, it relies on the expertise of specific technicians and knowledge gained over many years of experience. These scenarios can cause delays and errors from incorrect interpretations or lack of experience by the technician.

Additionally, while many heavy equipment manufacturers have made efforts to improve the collaboration between engineering and manufacturing, service continues to be isolated with limited collaboration or data continuity. These disconnects limit the visibility across your enterprise which creates data redundancies and quality escapes, preventing collaboration, data sharing and reuse across your organization.

Service excellence through planning

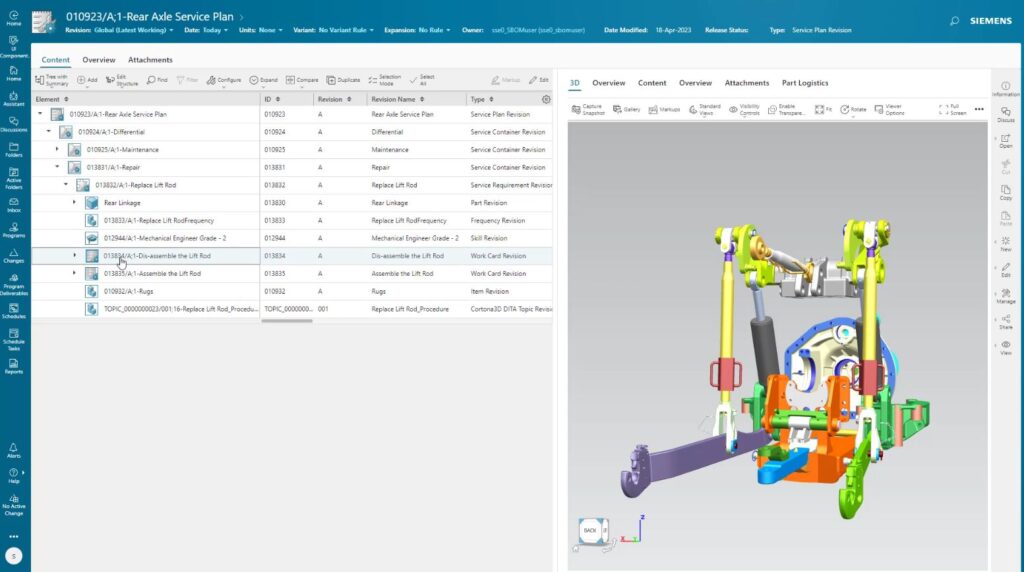

Service planning allows heavy equipment OEMs to manage all the service requirements for products within a fully integrated solution while evaluating service tasks collaboratively with design engineers to get earlier feedback that will improve the overall serviceability of products. Manufacturers will have the ability to define and manage service requirements with direct access to all available product data, like 3D models, drawings, and specification documents. This approach also provides clear visibility across all stakeholders to fully understand impacted service requirements, allowing for the full scope of potential changes to be quickly evaluated as your products evolve.

Service planning enables:

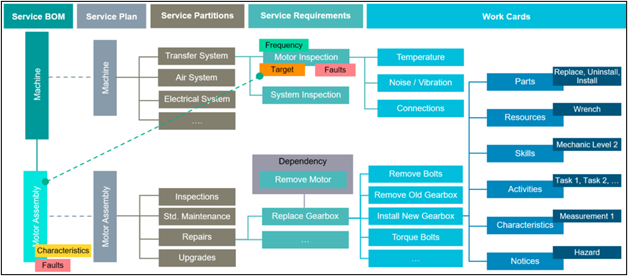

- Service requirements to be linked directly to associated parts and assemblies for clear traceability

- Dependencies between service requirements to ensure accountability of all requirements

- Detailed tasks with required resources, certifications and parts to accurately evaluate the full scope

- Linked fault codes and characteristics to ensure visibility of critical service details

Improving the serviceability of heavy equipment

To improve the overall serviceability of heavy equipment, you need integrated service planning that feeds into and leverages information from design and can be shared all the way to service execution. For example, design engineers can work with service engineers and planners early on in the product lifecycle to improve Design for Service (DfS). Service planners can link service requirements such as resource skillsets, required certifications and service tools to parts and assemblies.

The image below demonstrates integrated SLM visually with the many different aspects of service data and its relationship between functional domains, specific to a machine. Starting from the service BOM – to service planning and requirements – all the way to execution with Work Cards. Keeping the information in context and in sync will ensure that downstream users (service teams) will get accurate information, and upstream users (product design) can receive feedback from the field.

A model-based approach to service lifecycle management

Leveraging an integrated approach to service planning with service lifecycle management can significantly reduce the risk of identifying costly design issues too late in the product development cycle. You will also improve the overall traceability, visibility and reuse of all available data. Using a model-based and data-centric approach to service planning will allow heavy equipment manufacturers to:

- Reduce turn-around times by having clear visibility of service requirements for specific assets

- Increase quality and compliance with service requirements integrated into the change process

- Ensure the accuracy of information provided to the field through data-driven service documentation

The Siemens Teamcenter service lifecycle management (SLM) solution, based on a PLM backbone, provides a comprehensive approach to managing service planning and service activities across the machine lifecycle.

With Teamcenter SLM, you can create effective service plans to optimize service operations and reduce asset downtime. You can get detailed product and service information to teams that need to track and understand physical asset health. You can provide service technicians with a complete understanding of service needs so they are prepared to perform upgrades. And, you can feed service event data back to engineering, to close the loop between service and design for continuous product improvement. The image below shows the different capabilities available through service lifecycle management:

Learn how fully integrated Service Lifecycle Management can enhance the bottom line and turn heavy equipment service initiatives into increased revenue.

Additional resources for heavy equipment manufacturers about service lifecycle management:

Ebook: Service lifecycle management framework for heavy equipment

Blog: Improve heavy equipment serviceability with integrated service BOM management

Blog: PLM and CRM together: How to boost service revenue and customer loyalty