Revolutionize design: How CFD simulation enables 100% virtual critical equipment development

Engineers across energy, chemicals, and infrastructure sectors face the complex challenge of designing equipment that meets rigorous customer demands, regulatory requirements, sustainability targets, and budget constraints—all while racing against critical delivery timelines.

With competition and volatility growing, how can engineering teams make better design choices to meet project requirements and accelerate time-to-market? Here’s the answer: Embrace computational fluid dynamics (CFD) simulation from the beginning of your design cycle.

In our recent webinar, industrial combustion systems leader ClearSign Technologies Corporation presented its ultra-innovative, simulation-driven, CFD design processes, allowing it to design an extremely low-emissions burner 100% virtually without any physical testing.

Scroll down for webinar highlights and hear a remarkable success story from the world of simulation-driven design.

Introduce engineering simulation early on to improve design decisions and reduce costs

Pressure is growing on businesses to bring critical application equipment to market faster.

As presented by Giulio Camauli, Simcenter Industry Lead for Industrial Machinery at Siemens Digital Industries Software, front-loading engineering simulation empowers designers to verify assumptions and eliminate equipment defects early in the design process.

The result? Significant business cost savings and shorter development cycles.

Evaluate and optimize designs quickly using automated design exploration

Improving the efficiency of equipment such as burners has traditionally been very time-consuming, as engineers must manage multiple concurrent objectives at the same time.

By automating design exploration, engineers can quickly evaluate hundreds of solutions to optimize performance. Watch the clip to learn how advanced design automation increases engineering productivity while freeing resources for innovation-driven work.

Apply strategic CFD simulation to accelerate development while eliminating costly testing

When developing combustion equipment like burners, companies have relied heavily on costly, resource-intensive physical prototyping and testing.

As discussed in the webinar highlight by Matthew Martin, Chief Technology Officer, for ClearSign Technologies Corporation, the company relies on strategic CFD simulation to design and validate products virtually while eliminating physical testing.

Watch the clip to learn how businesses can embrace strategic CFD to:

- Accelerate equipment development timelines

- Optimize products digitally without extensive testing and prototyping

- Reduce overhead and development costs

Watch how ClearSign Technologies used Simcenter STAR-CCM+ CFD software to 100% virtually design a burner

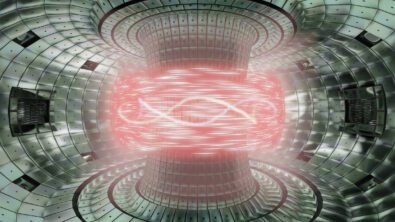

Using advanced complex chemistry modeling capabilities in Simcenter STAR-CCM+ CFD software, ClearSign Technologies successfully developed an ultra-fuel-efficient and sustainable burner 100% virtually without physical testing.

Watch the clip for an overview of how CFD-driven virtual development enabled ClearSign to achieve a perfect first startup and an unprecedented two ppm NOx emissions performance.

Embrace CFD simulation to revolutionize equipment development

By leveraging CFD simulation early in the design process, energy, chemicals and infrastructure businesses can design and optimize innovative equipment faster while reducing costs.

As industries continue to discover and embrace virtual product development, the insights shared by Siemens Digital Industries Software and ClearSign provide a roadmap to achieve dramatically improved design outcomes.

To learn how CFD software can help your engineering team and business, watch the full webinar.

Comments

Leave a Reply

You must be logged in to post a comment.

The charm of Poor Bunny is that it combines humor with danger. You’re controlling this adorable little bunny, but the game keeps throwing deadly obstacles in your way. It’s funny, challenging, and frustrating all at the same time. That mix of emotions makes it stand out from other arcade games I’ve played.

The article highlights the transformative power of CFD simulation in engineering, showcasing ClearSign’s success in creating innovative, sustainable designs. Embracing such tools can revolutionize industries. For more insights and solutions, visit bounce path—your pathway to innovation!

Players may concentrate on having fun instead of waiting around for lengthy downloads or intricate menus thanks to Cool Games Free‘s rapid play feature.

This post on CFD simulation blows my mind! I’ve seen similar tech really streamline processes in my own engineering projects, reducing wheelie life errors before prototyping. Excited to see how this evolves!