Nuclear innovation unleashed: The role of simulation in small modular reactor (SMR) design, optimization and safety

The need for reliable yet sustainable energy is growing steadily, particularly with AI data centers requiring significantly more power from existing grids each year. In this fast-changing energy landscape, nuclear power has reemerged as a crucial player as today’s only viable grid-scale source of carbon-free electricity.

Despite several notable accidents, nuclear power is the statistically safest form of energy and is emissions-free. However, traditional nuclear power plants have long delivery times of 10 to 15 years and very high costs.

Enter small modular reactors (SMRs), nuclear fission reactors that are smaller, more compact and faster to construct than traditional nuclear power plants. In this on-demand webinar, X-energy, a leader in the nuclear energy space, highlights how they use cutting-edge simulation software to design SMRs with enhanced safety features that can be constructed in only two to three years.

Scroll down for webinar highlights and learn how X-energy uses simulation to optimize SMR designs while improving safety and lowering costs.

X-energy wants to deliver nuclear reactors in faster timeframes and with higher cost certainty

A startup company whose goal is to change the nuclear power industry, X-energy was selected by the US Department of Energy to participate in its Advanced Reactor Demonstration Program using its Xe-100 nuclear reactors that it describes as simple, meltdown-proof and “walk-away safe.”

Along with helping provide electricity, X-energy wants to support decarbonizing other industries, including process. In this clip, Dr Martin van Staden, PhD, Vice President of Reactor Development at X-energy, provides an overview of this ultra-innovative nuclear company’s strategic goals.

Fuel pebbles are key to X-energy’s meltdown-proof small modular reactor design

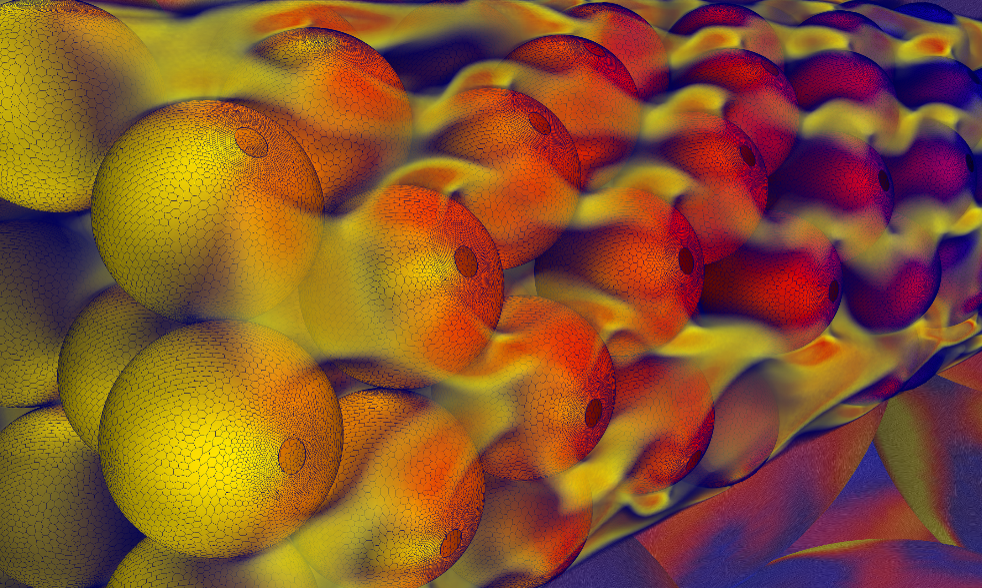

Unlike nuclear reactors that place traditional nuclear fuel pellets into zirconium steel tubes, X-energy’s reactors use tri-structural isotropic (TRISO) particle fuel pebbles that are individually approximately the size of a billiards ball.

Each pebble is made of graphite and silicon carbide particles that coat the uranium fuel while their melting temperatures are more than 3,000 degrees centigrade. These fuel pebbles are the key to X-energy’s reactor designs and enabled the company to design a meltdown-proof small modular reactor. Watch this webinar highlight for an overview of the fuel and reactor design.

Engineering simulation software was crucial for enabling X-energy’s intrinsically safe reactor design

X-energy used engineering simulation software to design a versatile yet simple reactor that can use steam to create electricity by adding a turbine. It can also connect to process heat plants and provide carbon-free steam directly to petrochemical and chemical plants.

A key benefit to X-energy’s reactor design are its built-in passive safety mechanisms. No operator action, active system or electrical power is required to ensure public safety.

In a scenario similar to Fukushima, where the facility loses power and cannot add cooling, the X-energy reactor would remain safe because it won’t burn down. The reactor would automatically shut down due to a low excess reactivity while maintaining a strong negative temperature coefficient. Discover more by watching this clip:

To analyze and optimize its reactor design, X-energy used Simcenter STAR-CCM+ CFD software

X-energy wanted to optimize its reactor design, control costs, and not compromise safety. It used Simcenter STAR-CCM+ CFD software to meet this goal, which lets engineers model complexity and explore the possibilities of products operating under real-world conditions.

Watch this clip to observe the capabilities of Star-CCM+ in helping X-energy simulate reactor safety in the equivalent of a Fukushima-type scenario.

Simulation is crucial in helping bring SMRs and advanced nuclear reactors to market

With carbon-free energy demands increasing every year, especially with the rapid growth and power requirements of AI data centers, small modular reactors are rapidly growing in importance.

Helping lead the way in SMRs, companies like X-energy are demonstrating the crucial role simulation will play in helping both nuclear power and non-nuclear power businesses achieve their power plant design and industrial energy management goals while bringing next-generation carbon-free energy solutions to market.

Ready to learn more about this subject? Watch the full webinar.

Comments

Leave a Reply

You must be logged in to post a comment.

drift hunters is a realistic car drifting game that lets players customize and drive powerful cars to perform smooth, stylish drifts. With detailed physics, multiple tracks, and tuning options, it’s perfect for racing and car enthusiasts.

It’s fascinating to see how X-energy leverages simulation software like Simcenter STAR-CCM+ CFD for safer small modular reactor designs. The emphasis on reliability and sustainability in nuclear innovation is truly commendable. This article sheds light on the crucial role!

wheelie life