Harnessing clean hydrogen

On the road to a profitable hydrogen economy

The H2 economy is gaining momentum, and it’s hard not to see why.

As a low-carbon fuel source, hydrogen is vital to reducing emissions and achieving sustainability goals. While more governments are rolling out their billion-dollar hydrogen strategies, an increasing number of companies are looking to capitalize on new business opportunities. At the same time, startups and new players are entering the scene—challenging the norms and driving competition. According to a McKinsey & Company research, by 2050, the demand for clean hydrogen could account for up to 73 to 100 percent of total hydrogen demand.

Industrial hydrogen production: Challenges and opportunities

But can hydrogen save the planet? Experts believe it depends on how it is produced. Today, more than 80% of hydrogen production relies on fossil-fuel-based processes, emitting significant emissions.

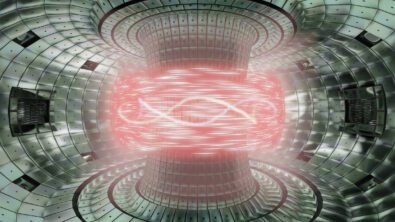

Enter clean hydrogen, a zero-emission fuel that can replace many of the high-carbon fuels across industries. Developed through the process of electrolysis using renewable or nuclear energy, clean hydrogen is considered to be a promising solution for the world’s decarbonization efforts, particularly in industrial sectors, such as steel, chemicals, and power generation.

According to research estimates, clean hydrogen projects have seen a dramatic increase worldwide, from 228 projects in 2021 to 1,572 in 2024, indicating a seven-fold increase. As a result, the manufacturing of electrolyzers, crucial for clean hydrogen production, is also expected to grow strongly in the coming years. In fact, it’s estimated that by 2026, the global electrolyzer capacity will reach 8.7 gigawatts due to large-scale hydrogen electrolysis projects planned across the globe. However, the long-term viability of these projects depends on addressing several challenges, including high capital costs, infrastructure availability, and the need for abundant renewable energy supplies.

“Digitalization can save the power industry about $80 billion per year by 2040, or 5% of total annual power generation costs.”

Digitalization and Energy, IEA

Accelerate digital transformation

Accelerating digitalization is crucial to overcoming these challenges. Suppose you’re an owner-operator, equipment manufacturer, or an engineering, procurement, and construction (EPC) business in the hydrogen industry. In that case, your success largely depends on how quickly you can speed up digitalization efforts and adapt to the evolving hydrogen market while taking advantage of new business opportunities. However, concerns remain. Most capital project teams struggle with project delays, time and cost overruns, interoperability issues, and document-driven legacy processes. But with the right tools and the latest technologies, you can make significant strides in this promising industry.

At Siemens, we thrive on challenging the status quo and turning complexities into a competitive advantage. With decades of experience with leading firms in the energy, chemicals, and infrastructure market, Siemens is uniquely positioned to help companies make the most of their technology investments and deliver their hydrogen projects on time and budget. Our solutions on enterprise asset management, adaptive hydrogen production, process automation, and cybersecurity, combined with next-generation design and collaboration software, can help you accelerate your digital transformation efforts and drive innovation and sustainability across the enterprise.

Staying adaptable in the hydrogen economy

Several organizations are exploring hydrogen applications with some claiming to have built thriving businesses. While they may be using advanced technologies to get there, only some take an end-to-end approach that true adaptability requires. Streamlining engineering and design processes, integrating operations and connecting the entire lifecycle of a plant or equipment using a robust digital foundation are essential prerequisites for the adaptability required today to successfully navigate the hydrogen economy of tomorrow. We recommend three digital threads to help you get there.

A digital thread is an integrated approach to solving your business challenges, combining the latest digital technologies to get organizations where they need to go, faster.

Scroll down to read more about each of the digital threads:

Integrated Design and Configuration

Begin by industrializing your engineering design processes, using multidiscipline design and reuse capabilities to engineer better designs, faster. Take a more modular and repeatable approach to power plant design and use advanced design automation to rapidly engineer custom solutions, while meeting industry regulations with an integrated, systems-driven approach.

Operational Excellence

Harness your industrial energy management data to continuously optimize and adapt your production in real time. Use an open industrial IoT platform to integrate core production processes, take advantage of the latest advances in process automation, and empower your engineering teams to collaborate seamlessly using an executable digital twin.

Digital Lifecycle Excellence

Take the pain out of integrating your engineering and project data and enable real-time collaboration throughout the asset lifecycle. Use enterprise asset management software to build a robust digital foundation and transform the performance of your capital projects to lower operational costs, maximize profitability, and achieve more predictable outcomes.

Roses are red; violets are blue, hydrogen too has many hues

Did you know different colors are used to label different types of hydrogen? Here is a breakdown of each color and what they mean:

Green hydrogen: Hydrogen is produced using renewable energy to electrolyze water into hydrogen and oxygen. Green hydrogen manufacturing relies on 100% renewable energy, making it the ideal fuel source to reach net-zero emissions goals.

Grey hydrogen: Hydrogen produced from fossil fuels, that release emissions such as CO2.

Blue hydrogen: Hydrogen produced through natural gas through steam methane reforming. However, the CO2 is captured, stored, and reused (carbon capture storage). It’s often seen as a cleaner option compared to grey hydrogen.

Pink hydrogen: Hydrogen produced via electrolysis, powered by nuclear energy. This type of hydrogen is considered environment-friendly due to its low emissions.

Read this infographic to learn more about the different colors of hydrogen.

Ready for a deeper dive?

Explore our white papers, ebooks and in-depth articles on hydrogen and stay informed on what’s shaping the next era of clean energy.

Discover more

Comments

Leave a Reply

You must be logged in to post a comment.

The H2 economy’s growth is indeed impressive, and it’s exciting to see the shift towards clean, low-carbon hydrogen fuels. With so many businesses and startups entering the space, it’s creating both opportunities and challenges. While you’re exploring emerging markets, it’s also important to consider a wide range of safety and compliance factors, including background checks for personnel.

A great overview of hydrogen’s role in decarbonization. The emphasis on digitalization and lifecycle integration is key—without tackling costs, infrastructure, and efficiency, the hydrogen economy can’t scale sustainably. Exciting to see how technology can accelerate this transition.

Great read on hydrogen’s growth—clean H2’s potential for decarbonization is exciting! Love that it highlights digitalization as a key fix for cost/infrastructure hurdles. Quick, insightful breakdown of opportunities (and colors!)—spot-on for anyone following the H2 economy. https://sora-2-ai.com/

Caution: Each jump must be timed perfectly to avoid obstacles, making every moment in geometry dash meltdown thrilling and intense!

The old rules of Titan Reforged Classic gold farming still apply, but only partially. In Titan Reforged, the smartest players are those who anticipate market trends, invest in high-demand professions, and leverage new systems like Titan Embers.

In a world of fluid motion and falling stars your arrows trace the silent path of fate while ragdoll archers unblocked dance through the weightless grace of every shot.

Digitalization is the only way to make the hydrogen economy actually profitable—Siemens really nailed the end-to-end approach here. https://squido.ai/