Fall Semiconductor Series: How integrated software and automation transform fab sustainability

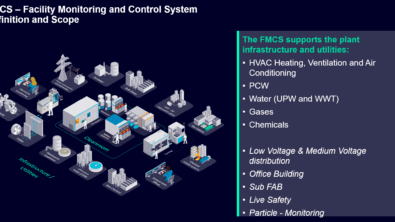

(Part 4 of 5): How the Siemens Facility Monitoring and Control System (FMCS) moves sustainability forward

In our Fall Semiconductor Series, we discuss the sustainability challenges faced by semiconductor fabs and why an integrated software and automation solution is the right solution to address these challenges. If you missed our earlier posts, just click on Part 1, Part 2 or Part 3 of the Series.

In this week’s blog, we focus on the integrated Siemens FMCS and how it moves sustainability forward by equipping fabs to streamline workflows, enhance quality control, optimize resource and plant efficiency, and boost throughput.

Lowering energy consumption, eliminating waste generation, reducing chemical usage and regulating process cooling water (PCW) are critical points on the sustainability journey. Next steps such as selecting environmentally friendly materials and less regulated substances, properly sizing electrical equipment and sourcing alternatives to polyfluoroalkyl substances (PFAS) can significantly decrease the environmental impact.

Water: essential to life and semiconductor lifecycles

Water is the lifeblood of semiconductor manufacturing, with a single chip requiring thousands of gallons of ultra-pure water (UPW) during production. Each chip undergoes hundreds of cleaning steps using deionized water that is 1,000 times purer than tap water, since even microscopic contaminants can cause device failure.* With fabs consuming millions of gallons daily for cleaning, cooling and maintaining ultraclean environments, water conservation and recycling are critical for sustainable manufacturing.

That is why we must safeguard this most essential resource of all, by incorporating water-efficient technologies to minimize high-volume usage of UPW and wastewater creation with wastewater treatment processes (WWP).

Informed by real-time fab and subfab performance data, the digital twin can create highly effective models for use in carbon reduction, material selection, energy and resource management, chemical usage, usage of gases, water conservation and other vital steps to reduce environmental impact and help improve your sustainability KPIs.

Sensors and dashboards monitor the pulse of progress

MES and semiconductor specific dashboards provide sustainability analysts with the real-time information they need to both monitor the status of gas levels and to plan any changes in gas usage needed to improve the manufacturing process.

As mentioned above, about 30 percent of semiconductor fabrication emissions result from using process chemicals that enter the atmosphere during manufacturing.

As a result, manufacturing emissions must be carefully monitored and processes that produce emissions must be optimized. A sizable portion of the process chemicals used in a semiconductor fab are gases, which play critical roles in various stages of semiconductor manufacturing, including deposition, etching, doping and cleaning.

Each process gas must be managed carefully. Due to the miniaturization of semiconductor components, most gases must be available at the highest levels of purity. Not surprisingly, some of these gases are potentially hazardous to personnel and the environment.

Gases stored in the subfab and used throughout the fab require stringent safety measures and leak detection systems. Sensors must be strategically positioned throughout the fab and subfab to measure both the purity and security of gases stored in the subfab, while tracking and minimizing the gases used and discharged during the fabrication process.

Emissions from semiconductor fabrication are strictly regulated under international laws, and in the U.S., under both federal and state laws. This is where sensor data, sensor dashboards and Siemens sensor technology become critically important tools for optimizing sustainable processes.

Smart manufacturing puts the right data at your fingertips

Process engineers using AI can leverage the full spectrum of sensor data to fine-tune MES to run more efficiently while maintaining performance and quality.

Fortunately, change scenarios involving gases can be evaluated virtually using the digital twin at a fraction of the cost of testing different scenarios during the actual process.

Ion implementation, a common process used in semiconductor fabrication to implant dopant atoms into semiconductor materials, requires a variety of gases. Typically, gases such as boron trifluoride (BF3), arsine (AsH3), and phosphine (PH3) are selected. Each of these gases must be monitored for safety, since they can be highly toxic and corrosive, and for process control, since a stable and clean process environment is essential.

The search for sustainable alternatives

Fortunately, there is a growing emphasis on minimizing the environmental impact of gas usage, including the reduction of greenhouse gas emissions. For example, the growing use of fluorine, which has a global warming potential of zero,** can help to reduce the use of other greenhouse gases currently used to clean chemical vapor deposition (CVD) chambers. In addition, recycling systems for gases like neon are also being implemented, where gases are captured and purified, enabling their reuse in semiconductor manufacturing while reducing environmental impact and ensuring supply chain resilience. This circular approach, which can be modeled during sustainability planning with the digital twin, transforms what was once waste into a valuable resource, demonstrating how sustainable practices can enhance both environmental and operational efficiency.

Next week, we will explore the story of integration farther to detail why smart manufacturing is the key to synchronizing software, data sets and automation.

Read the eBook, “Using integrated software and automation to transform fab sustainability.”

To discover more, download our compelling eBook, “Using integrated software and automation to transform fab sustainability.”

*X Future-Bridge.US Blog: “Water Systems in Semiconductor Fabs,” May 16, 2025, https://future-bridge.us/di-water-systems-in-semiconductor-fabs/#:~:text=Water%20purity%20to%20the%20parts,%2C%20and%20silica%20%3C0.5%20ppb

**Leading to a Cleaner World, The Linde Group, Pages 2, 3, https://static.prd.echannel.linde.com/wcsstore/FR_RES_Industrial_Gas_Store/Assets/produits-et-approvisionnement/Linde-On-Site-Fluorine-Generation-Brochure_tcm201-17647.pdf